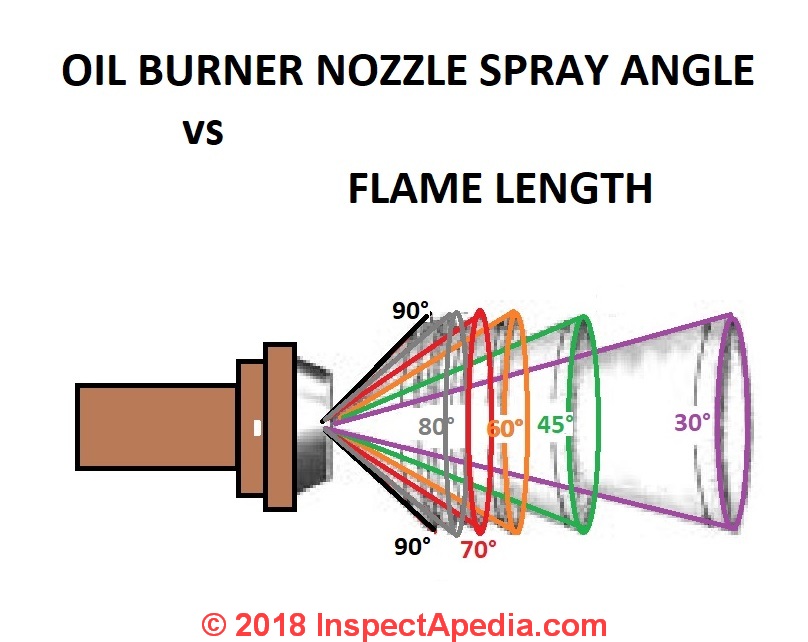

Our burners are suitable for a multitude of needs. Beckett recommends a hago.65 60° “b” nozzle for my burner/boiler combination. After reading/researching, i have found that these are recommended more for larger commercial type systems and also have a louder burn volume. Web here's how to figure the right nozzle: This is a solid cone type pattern.

Your chart sparked me to do some more research and i found the hago site that outlines their nozzles. Web see figure 2 above. Light oil ratings based on no. Cf500 oil burner | 1.75 to 5.50 gph | ac power and cf800 oil burner | 3.00 to 8.00 gph | ac power. This is a solid cone type pattern.

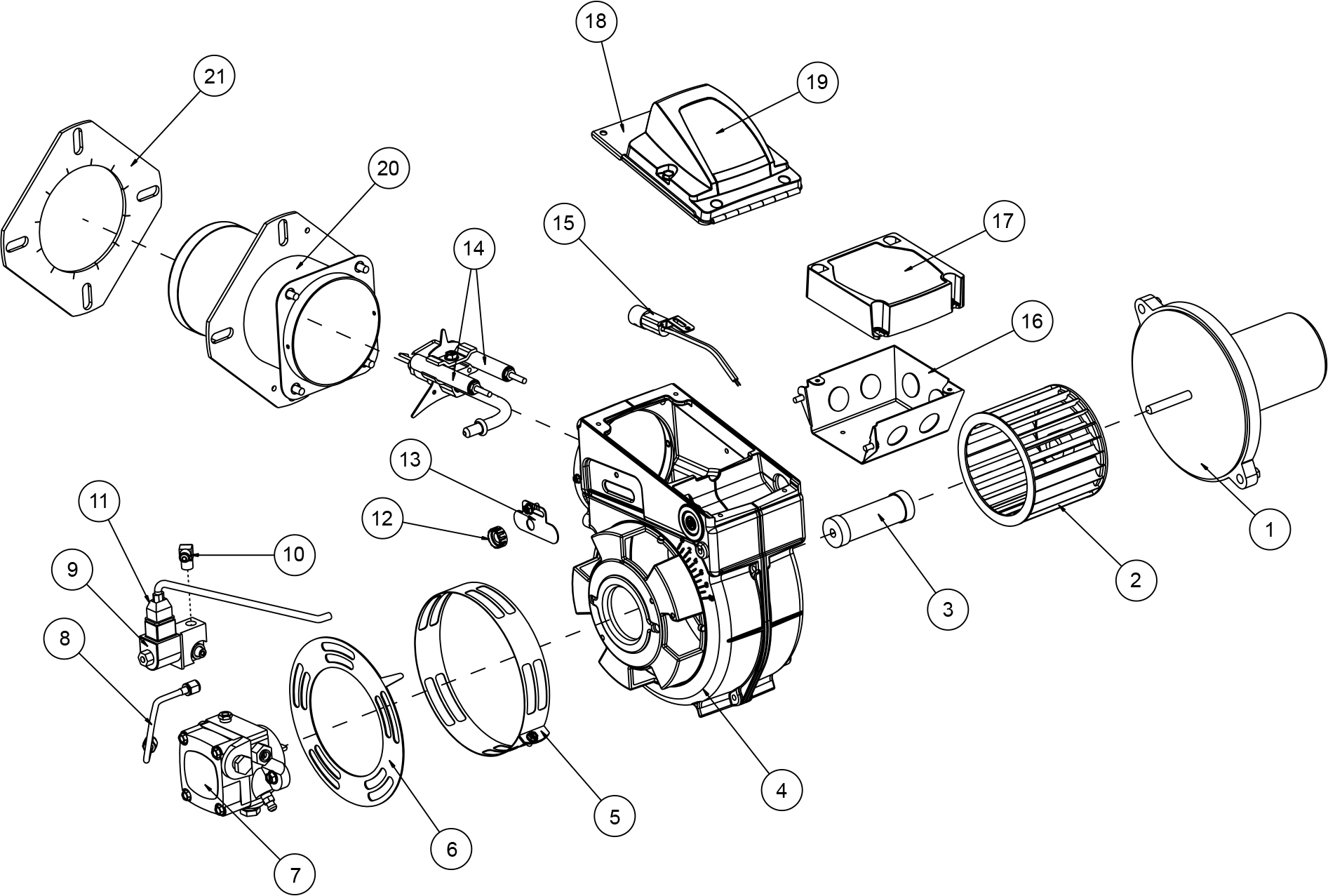

That is the way the correct nozzle is determined in the laboratory. Web the cross reference chart provides a quick look up of different manufacturers nozzles. Here are some other factors. Web the important ‘z’ dimension is the distance from the face of the nozzle to the fl at face of the head (or heat shield, if applicable). Our utilization of advanced components results in higher efficiency and reliability, all while reducing carbon emissions.

Web the cross reference chart provides a quick look up of different manufacturers nozzles. Web you can use our handy oil separator sizing tool to calculate a sizing report. After reading/researching, i have found that these are recommended more for larger commercial type systems and also have a louder burn volume. Then, you'll be taken right to the product that will work best. That is the way the correct nozzle is determined in the laboratory. The important z dimension is the distance from the face of the nozzle to the flat face of the head (or heat shield, if applicable). One of those, often the oil burner, will include the recommended oil burner nozzle size and pattern type. Web see figure 2 above. Our burners are suitable for a multitude of needs. Our utilization of advanced components results in higher efficiency and reliability, all while reducing carbon emissions. The flare fitting appears to be seated firmly before tightening back up, but i see the beginning threads of the assembly are slightly stripped. Web actualy the 60.80p is the exact spec nozzle from and allover my cmf80po's directions and spec sheet on the burner it self. Web how to diagnose oil burner smoke, smells, or odors: Web beckett is a managing partner of the firm and leads the estate planning and probate department where he practices in the areas of estate planning, probate and trust administration, as well as real estate, tax law, and commercial law. These diagnostic questions and answers can help you diagnose heating oil burner odor or smoke complaints.

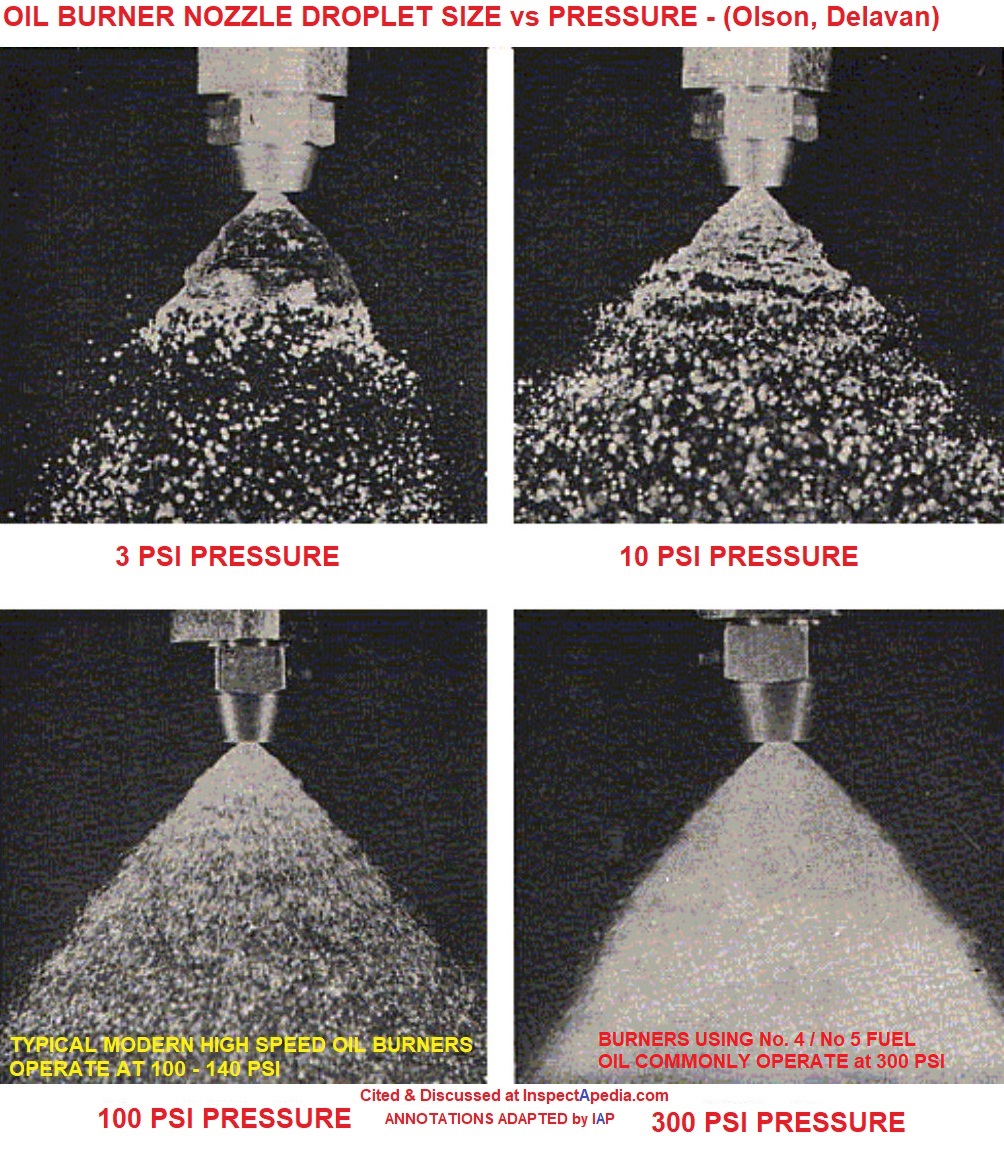

Using The Chart In The Back Of The Oem Guide Will Helpe You Determine Flow Rates At Elevated Pump Pressures.

A/c equipment a/c condensing units residential. The burner combustion system is a factor as is the chamber size and shape. Beckett recommends a hago.65 60° “b” nozzle for my burner/boiler combination. Details about oil burner nozzles are.

Our Burners Are Suitable For A Multitude Of Needs.

Then, you'll be taken right to the product that will work best. Cf500 oil burner | 1.75 to 5.50 gph | ac power and cf800 oil burner | 3.00 to 8.00 gph | ac power. Web when changing the burner nozzle (75/80 a) i have a small leak at the flare on the beckett afg nozzle assembly. Web see figure 2 above.

Web Use The Flow Rate Chart In The Back Of The Oem Guide, Page 100.

These diagnostic questions and answers can help you diagnose heating oil burner odor or smoke complaints. This is only a starting point in determining the proper replacement nozzle. Slide the nozzle if the air tube has a line forward or back until this dimension is 1 the acorn nut. 2 fuel oil with heating value of 140,000 btu per gallon.

Web The Important ‘Z’ Dimension Is The Distance From The Face Of The Nozzle To The Fl At Face Of The Head (Or Heat Shield, If Applicable).

I can confirm that it has a loud burn sound. Our burners are suitable for a multitude of needs. This article series describes the cause and cure for just about any odor or smell at or near an oil burner, where it comes from, what it means, and what needs to be done about it. That is the way the correct nozzle is determined in the laboratory.