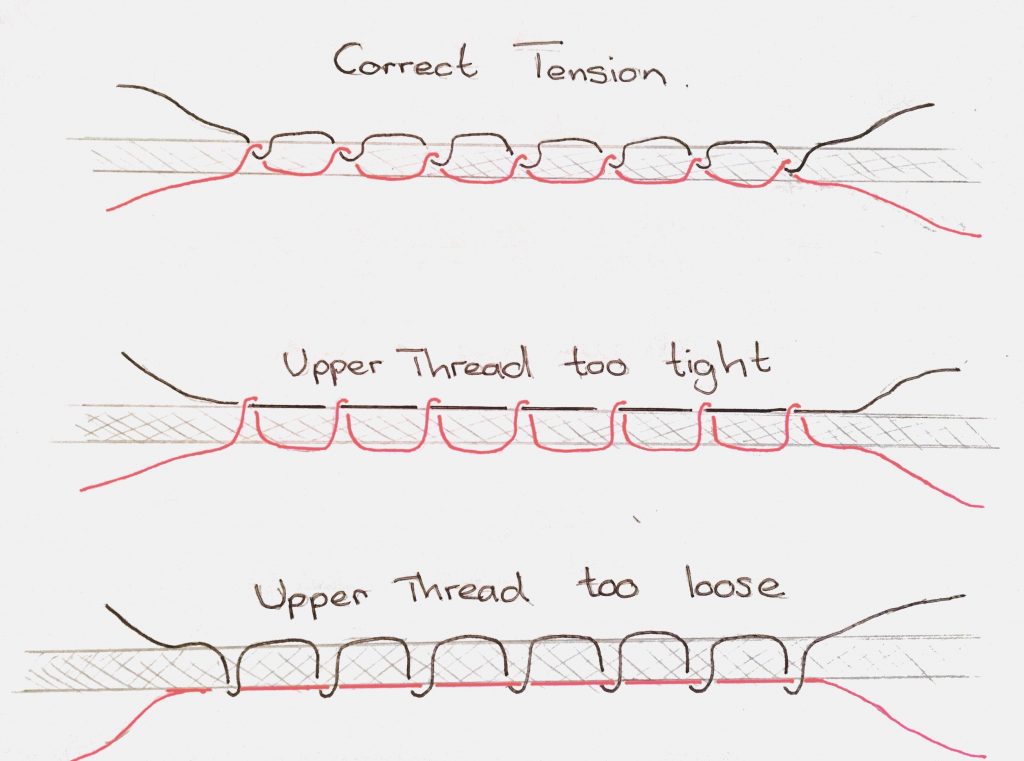

Are your stitches just looking wonky and not very strong or even? Web the bobbin tension is only a part of the sewing machine tension and must work in conjunction with the needle tension. Sounds like your sewing machine tension is out of whack or your bobbin is behaving badly! Bobbin thread showing up on the top side + the top thread stays straight = upper t is too tight. Web bobbin tensions should be 18 to 22 grams (up to 25 grams when embroidering caps).

Proper tensions for satin stitches should reveal 1/3 bobbin and 2/3 top thread color on the underside of the embroidery as seen on the image above. Web bobbin tensions should be 18 to 22 grams (up to 25 grams when embroidering caps). This is very helpful as it allows you to quantify the amount of tension placed on a bobbin thread, so you have a benchmark to base bobbin tension. Web the towa bobbin tension gauge puts a numerical value to the amount of tension placed on a bobbin. And turn the screw in tiny increments as you adjust.

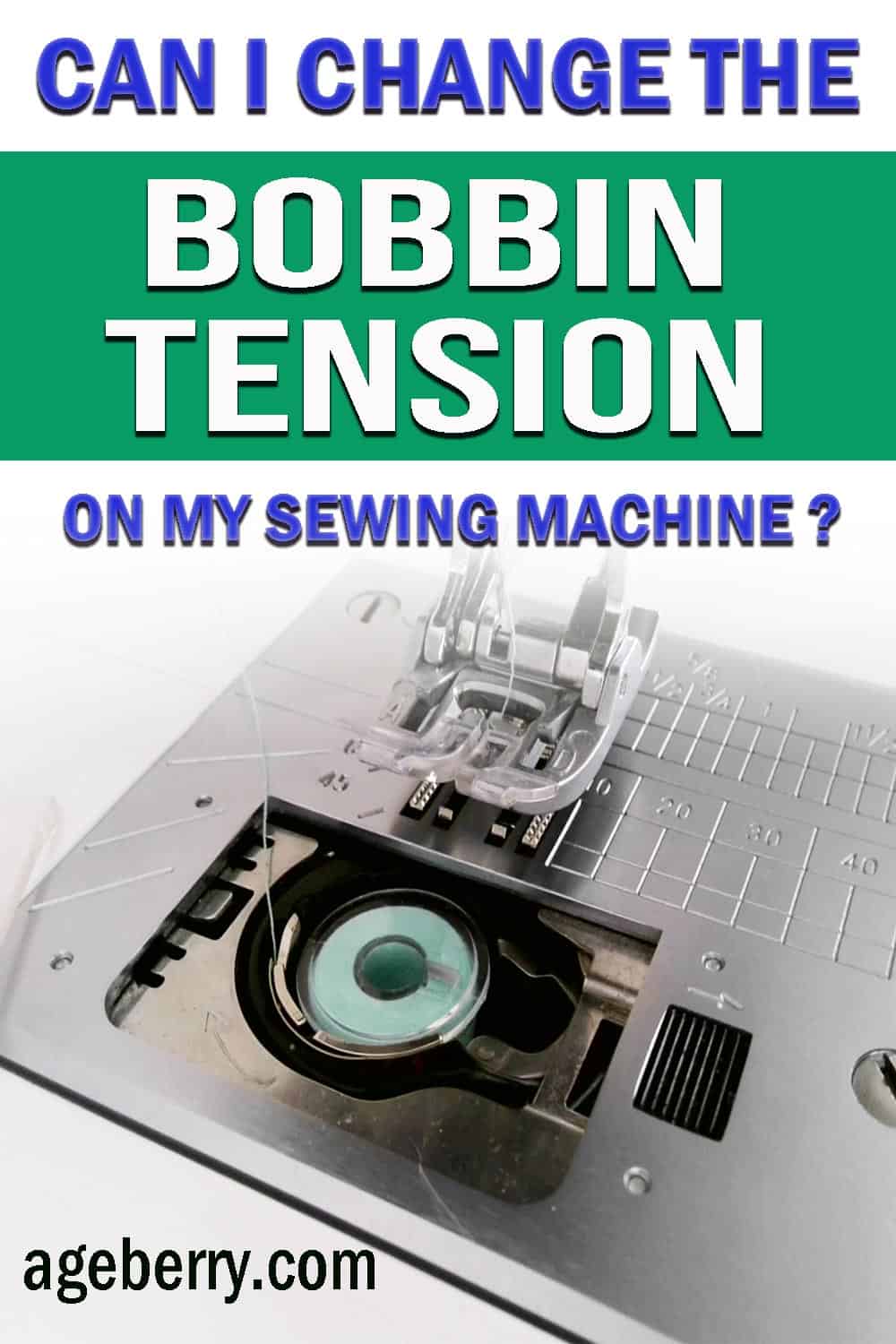

Let’s talk about how to check to see if it is and how to fix bobbin tension on your sewing machine. Web you can adjust the bobbin tension in your sewing machine by turning the tension spring screw in the bobbin case to the right to tighten the tension and to the left to loosen tension. Web we used our superbobs prewound bobbins in our towa to determine the optimal tension number (settings). Proper tensions for satin stitches should reveal 1/3 bobbin and 2/3 top thread color on the underside of the embroidery as seen on the image above. Web follow this sewing machine tension guide to learn how to make the most of your sewing machine’s tension mechanism!

This is very helpful as it allows you to quantify the amount of tension placed on a bobbin thread, so you have a benchmark to base bobbin tension. Set it, put the bobbin case into your machine, and forget it. If the top thread is a thick, 30 wt. Bobbin tension (otherwise called bottom tension) is usually set at a factory for all standard sewing threads. Find the screw for tension settings. Follow the video to learn the “drop” test to set your bobbin tension. Top thread showing up on the underside + the bobbin thread stays straight = upper t is too loose. Proper tensions for satin stitches should reveal 1/3 bobbin and 2/3 top thread color on the underside of the embroidery as seen on the image above. Web shop for towa bobbin tension gauges at superior threads and enjoy free shipping on orders over $50 within the u.s.! Bobbin thread showing up on the top side + the top thread stays straight = upper t is too tight. Web we have a video that shows these 6 steps to perfect tension. Web it is important to keep a total balance between your upper thread (top thread) and your lower thread (bobbin thread). Web to make it easy to understand: Are your stitches just looking wonky and not very strong or even? Bob purcell (chief threadologist of superior threads) discusses when adjusting the tension on a bobbin case is necessary.

The Bobbin Tension Used For Each Circle Is Shown In Grams.

Web to make it easy to understand: Are your stitches just looking wonky and not very strong or even? Web bobbin tensions should be 18 to 22 grams (up to 25 grams when embroidering caps). Proper tensions for satin stitches should reveal 1/3 bobbin and 2/3 top thread color on the underside of the embroidery as seen on the image above.

By Doing So, You’ll Be Able To Sew Beautiful, Even Stitches Every Time.

Find the screw for tension settings. Simply turning the tension screw on a bobbin case a. To obtain the correct tension setting, perform a test with the fabric and thread you plan to use for your Web if you’re having trouble with your stitches looking uneven, the chances are that your bobbin tension is not set correctly.

You Would Not Need Any Adjustment For A Greater Part Of Your Journey.

When your tensions are correct, you will see three fairly evenly divided sections on the back of your lettering or embroidery in each segment. Proper tensions for satin stitches should reveal 1/3 bobbin and 2/3 top thread color on the underside of the embroidery as seen on the image above. Let’s talk about how to check to see if it is and how to fix bobbin tension on your sewing machine. A clean bobbin case is essential for proper tension settings.

A Clean Bobbin Case Is Essential For Proper Tension Settings.

Bobbin thread showing up on the top side + the top thread stays straight = upper t is too tight. Web we have a video that shows these 6 steps to perfect tension. Essentially, the metal case you put the bobbin in before you load the whole thing in your machine has a tiny screw on the side. If the top thread is a thick, 30 wt.