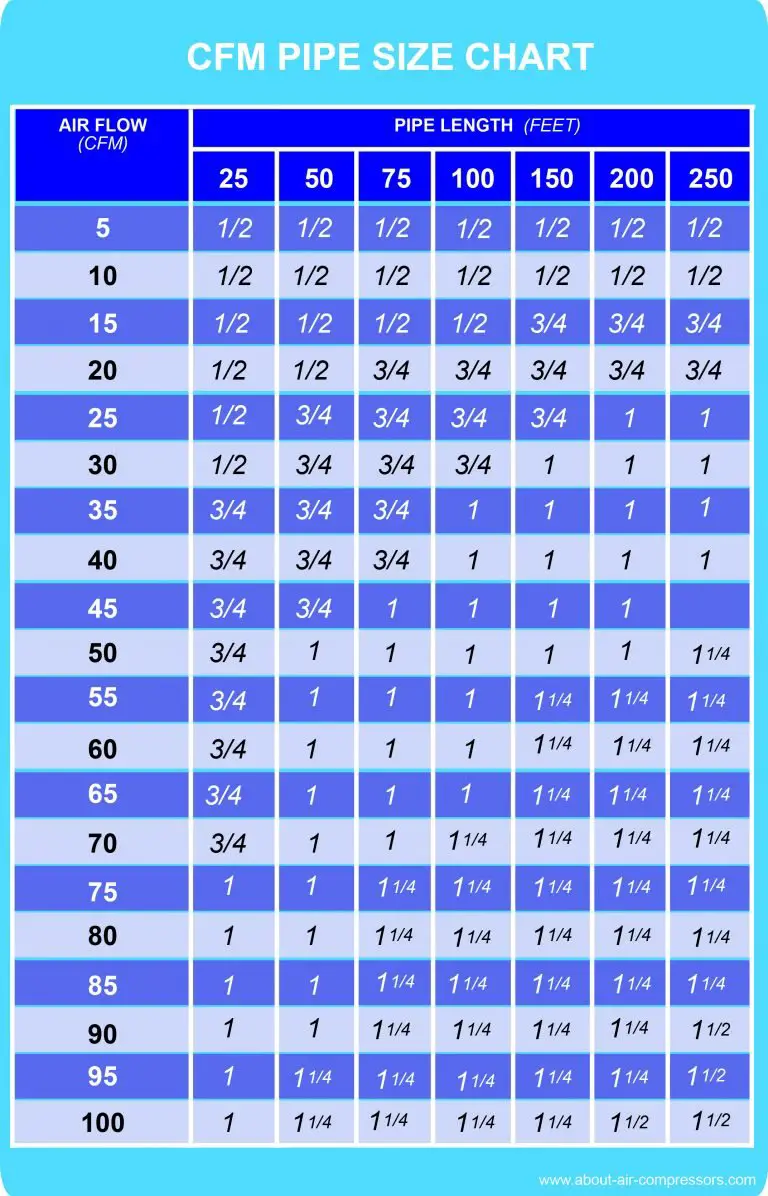

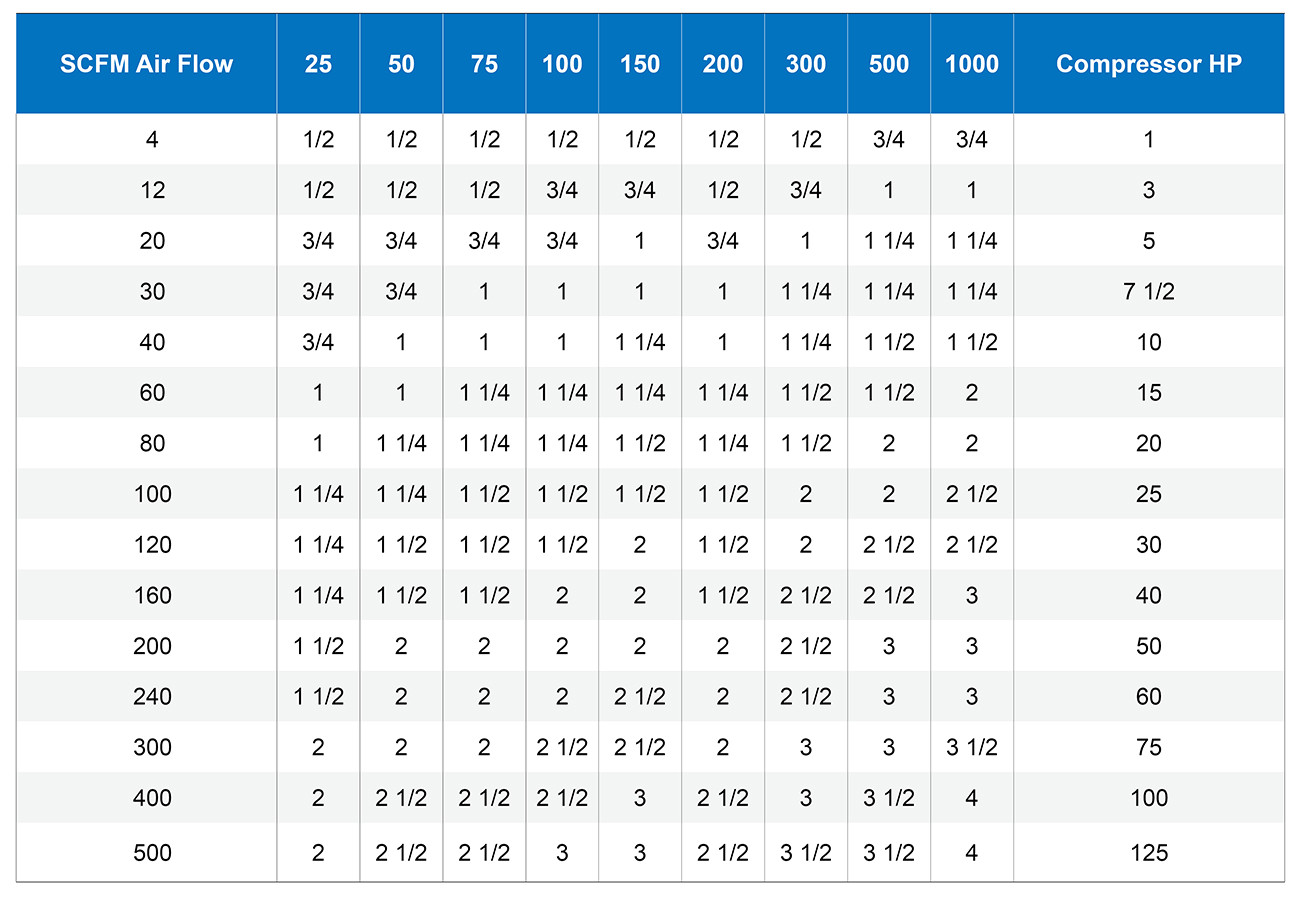

Measure and write the corresponding lengths of pipe on your schematic, then total the length of all straight pipes needed and note that on your. So, you want to know the correct pipe size for your compressed air installation? Air pipe lines capacities at pressure 100 psi (6.9 bar). With these two values, you can refer to an air compressor pipe size chart to. [ninja_tables id=”3644″] the table above measures airflow in cfm (cubic feet per minute) and measures the length of the pipe in feet.

Web to know what size compressed air pipe you need, you must know the length of your intended system and the cfm you intend to flow through. Draw a piping schematic and show all pipe fittings, valves, etc. It's easy, i'll explain how. Web calculate the correct pipe size for your compressed air system. Determine your air compressor’s maximum cfm.

Refer to pipe sizing charts or tables provided by pipe manufacturers, industry standards, or compressed air system design references. The table below gives the exact pipe size needed for each specific airflow and piping distance. It's easy, i'll explain how. Measure and write the corresponding lengths of pipe on your schematic, then total the length of all straight pipes needed and note that on your. Web pipe sizing charts:

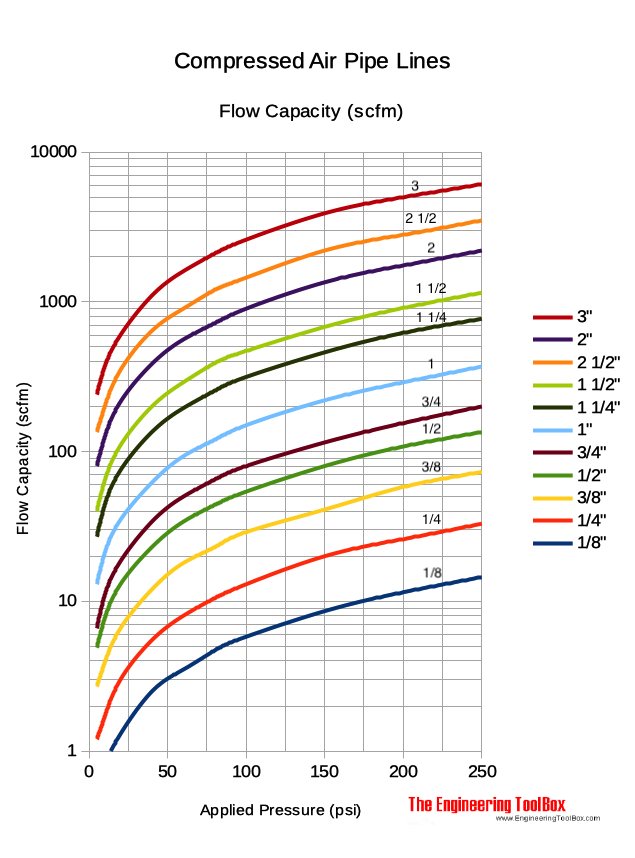

Make a piping diagram containing all pipe diameters, connections, regulators, and twists. With these two values, you can refer to an air compressor pipe size chart to. These charts relate pipe diameter, flow rate, pressure drop, and velocity, helping you select the appropriate pipe size for your specific application. Measure and write the corresponding lengths of pipe on your schematic, then total the length of all straight pipes needed and note that on your. Web calculate the correct pipe size for your compressed air system. Short paths in the system should be measured and added together. Refer to pipe sizing charts or tables provided by pipe manufacturers, industry standards, or compressed air system design references. It's easy, i'll explain how. Determine your air compressor’s maximum cfm. Air pipe lines capacities at pressure 100 psi (6.9 bar). To make an accurate determination of the maximum cfm demands of your system, you would need to conduct a study. [ninja_tables id=”3644″] the table above measures airflow in cfm (cubic feet per minute) and measures the length of the pipe in feet. Web pipe sizing charts: Web to know what size compressed air pipe you need, you must know the length of your intended system and the cfm you intend to flow through. So, you want to know the correct pipe size for your compressed air installation?

The Table Below Gives The Exact Pipe Size Needed For Each Specific Airflow And Piping Distance.

It's easy, i'll explain how. Short paths in the system should be measured and added together. Determine your air compressor’s maximum cfm. [ninja_tables id=”3644″] the table above measures airflow in cfm (cubic feet per minute) and measures the length of the pipe in feet.

Draw A Piping Schematic And Show All Pipe Fittings, Valves, Etc.

Web steps to figuring what size piping your compressed air system needs: Air pipe lines capacities at pressure 100 psi (6.9 bar). Web to figure out exactly how big ducts you need for central air conditioning systems, we have prepared complete cfm duct charts for all different kinds of ducts: Web to find the right size of piping for your air compressor, you must take into account the maximum cubic feet per minute (cfm) requirements of your system.

Keep In Mind That The Pipe Size Is Measured In Inches.

Web calculate your system’s maximum cfm. Web to know what size compressed air pipe you need, you must know the length of your intended system and the cfm you intend to flow through. Measure and write the corresponding lengths of pipe on your schematic, then total the length of all straight pipes needed and note that on your. So, you want to know the correct pipe size for your compressed air installation?

With These Two Values, You Can Refer To An Air Compressor Pipe Size Chart To.

To make an accurate determination of the maximum cfm demands of your system, you would need to conduct a study. Web pipe sizing charts: Refer to pipe sizing charts or tables provided by pipe manufacturers, industry standards, or compressed air system design references. Make a piping diagram containing all pipe diameters, connections, regulators, and twists.