I have a dewalt dcf601 that i use for technical work and it would be amazing to know that the torque specs called for in some install instructions correspondent to one of my clutch. Speed is required to drive the screw, but torque is what allows it to keep going when it needs to fight the stopping force of friction. Rotate the torque adjustment collar to align the desired torque setting with the narrow indicator on the tool housing. For example, the dcd996 is rated at 820 uwo with a 5ah dcb205 battery. Most of understand speed, it’s how fast the drill rotates the bit.

Setting 3 is the highest speed and is meant. Web the drill’s power rating is measured by its units watts out (uwo), the point where the drill’s speed and torque output are the highest. Web start with lower torque settings, then advance to higher torque settings to avoid damage to the workpiece or fastener. This may seem like common knowledge, but i hope it's helpful to some. Web the speed and torque numbers for the dcf899 are below.

Setting 3 is the highest speed and is meant. Setting 2 is a medium speed/torque and can be used for drilling or driving. For example, the dcd996 is rated at 820 uwo with a 5ah dcb205 battery. Make some practice runs in scrap or on unseen areas of the workpiece to determine the proper position of the mode selection collar. Remember to start with a low torque setting and gradually increase it as needed to.

The 1st mode gives torque as much as it can while the rpm is dropped. Web the numbers on a drill driver refer to the amount of torque the drill will apply to a fastener (usually a screw) and once that torque setting is reached, the drill will stop turning/driving the fastener. 20v max* 1/2'' high torque impact wrench. Setting 2 is a medium speed/torque and can be used for drilling or driving. Clutch position #2 is set to engage at apx 60 ft lbs of torque (same as competitive hammers) Web there are two basic ways to rate a drill’s power: Remember to start with a low torque setting and gradually increase it as needed to. Web today i’m going to walk you through how to properly adjust the speed, torque, and clutch settings on your cordless drill. Web dewalt uses uwo or unit watts out as a basis of measurement for our cordless drills vs. Dcf900 impact driver pdf manual download. Web the dewalt drill torque settings chart encapsulates the essence of precision and expertise that dewalt stands for. Web once you’ve drilled the hole to your desired depth, press the ‘forward/reverse’ button to change the drill into the reverse setting. By understanding its intricacies, applying the recommended settings, and following expert tips, you can elevate your drilling projects to new heights of accuracy and finesse. This mode is usually used for tougher jobs like drilling. Web the speed and torque numbers for the dcf899 are below.

Speed Is Required To Drive The Screw, But Torque Is What Allows It To Keep Going When It Needs To Fight The Stopping Force Of Friction.

Make some practice runs in scrap or on unseen areas of the workpiece to determine the proper position of the mode selection collar. 20v max* 1/2'' high torque impact wrench. Web view and download dewalt dcf900 instruction manual online. Web the 1 and 2 on a dewalt drill signify the speed settings.

Web The Dewalt Drill Torque Settings Chart Encapsulates The Essence Of Precision And Expertise That Dewalt Stands For.

The higher a drill’s power rating, or uwo, the faster it will perform on the jobsite. Dcf900 impact driver pdf manual download. Most of understand speed, it’s how fast the drill rotates the bit. Web once you’ve drilled the hole to your desired depth, press the ‘forward/reverse’ button to change the drill into the reverse setting.

Web The Torque Setting On A Dewalt Drill Depends On The Model And Type Of Drill.

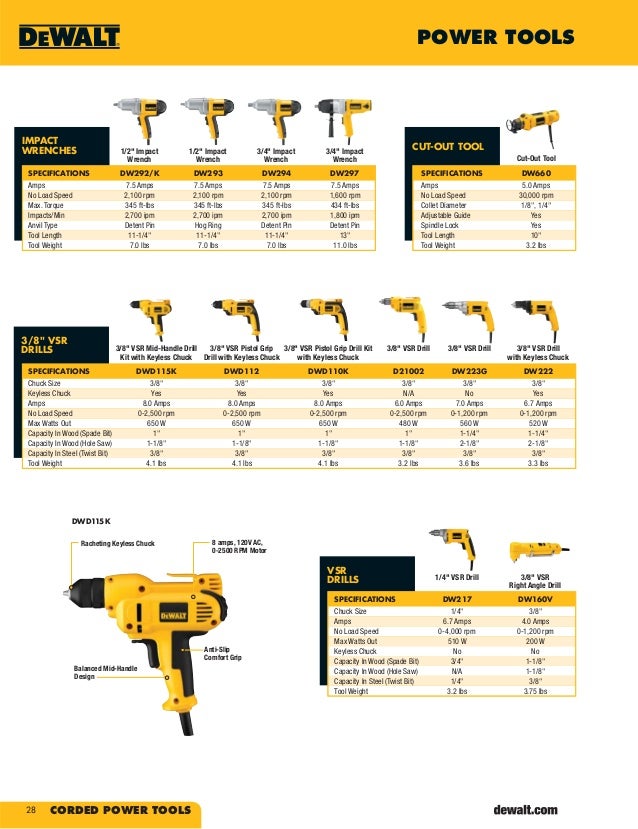

Web consult dewalt industrial tool's entire dewalt catalog catalogue on directindustry. The 1st mode gives torque as much as it can while the rpm is dropped. Web dewalt uses uwo or unit watts out as a basis of measurement for our cordless drills vs. Please always refer to the instruction manual for any additional operating instructions and.

Web Today I’m Going To Walk You Through How To Properly Adjust The Speed, Torque, And Clutch Settings On Your Cordless Drill.

This position has enough torque for 90% of all drilling applications. Rotate the torque adjustment collar to align the desired torque setting with the narrow indicator on the tool housing. Setting 2 is a medium speed/torque and can be used for drilling or driving. Web set the desired torque:

![Cordless Drill Torque Chart With [High Torque Drills 2024]](https://toolminer.com/wp-content/uploads/2020/03/Cordless-Drill-Torque-Chart-2048x1365.png)