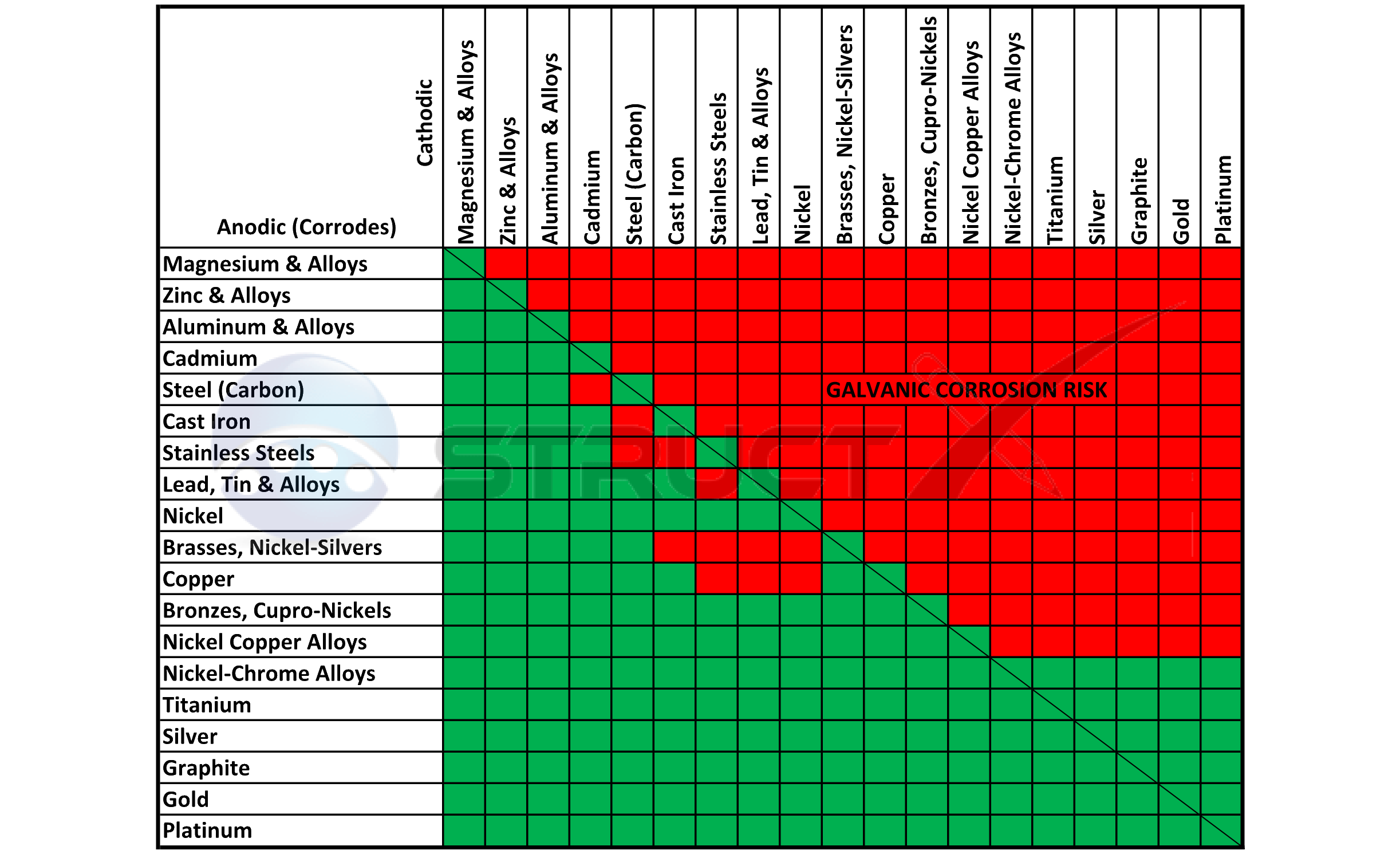

Web this article examines how dissimilar metals can lead to galvanic corrosion. Web below, we give a brief overview of galvanic corrosion and provide a galvanic corrosion chart to help fabricators and machinists avoid using the wrong metal. Contact a corrosion specialist to determine the best. Web there are two primary types of galvanic cells that cause corrosion: Web a phenomenon known as galvanic corrosion occurs when dissimilar metals, subjected to the same environment, comprised of a conducting solution, are in direct electrical contact.

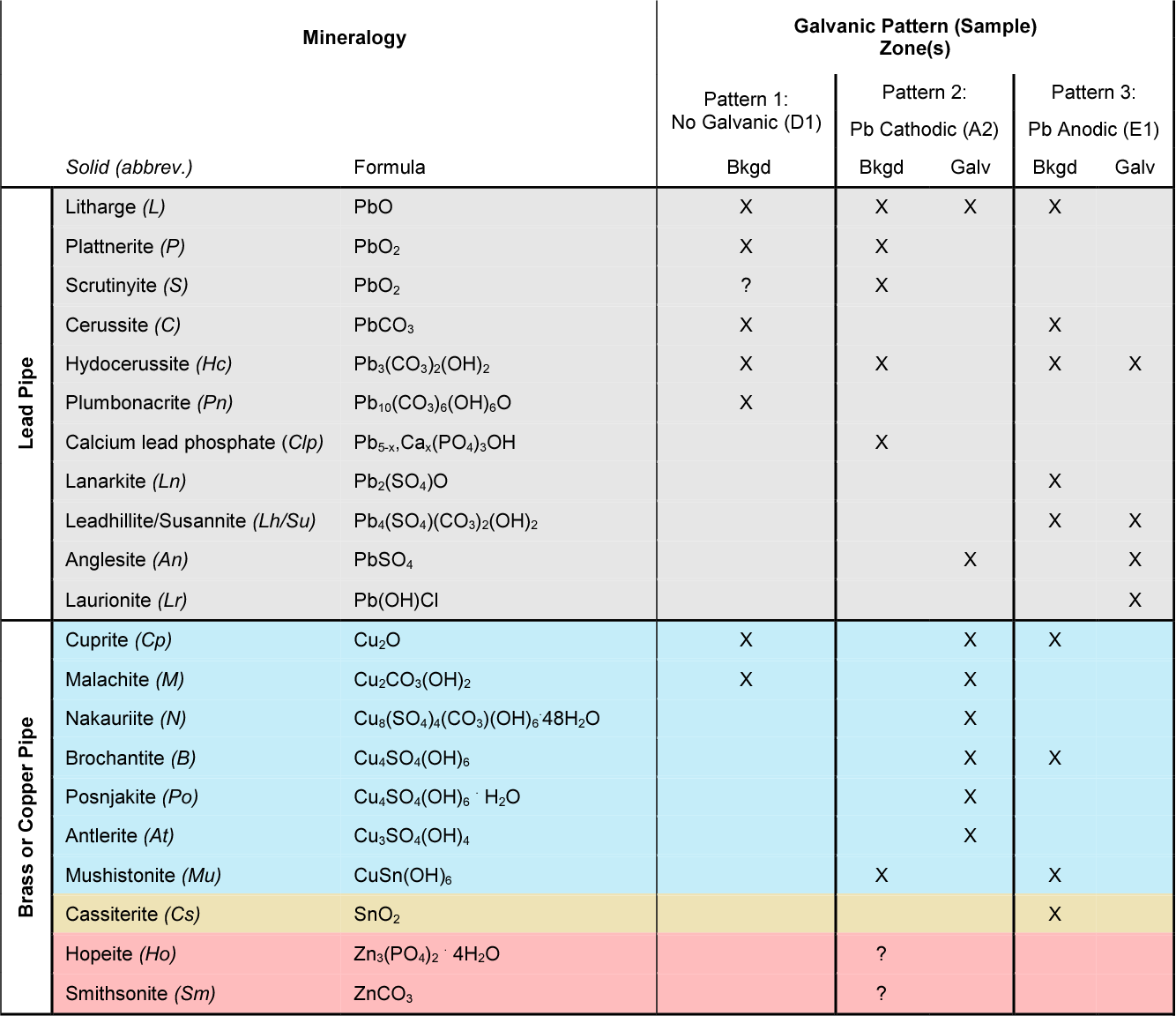

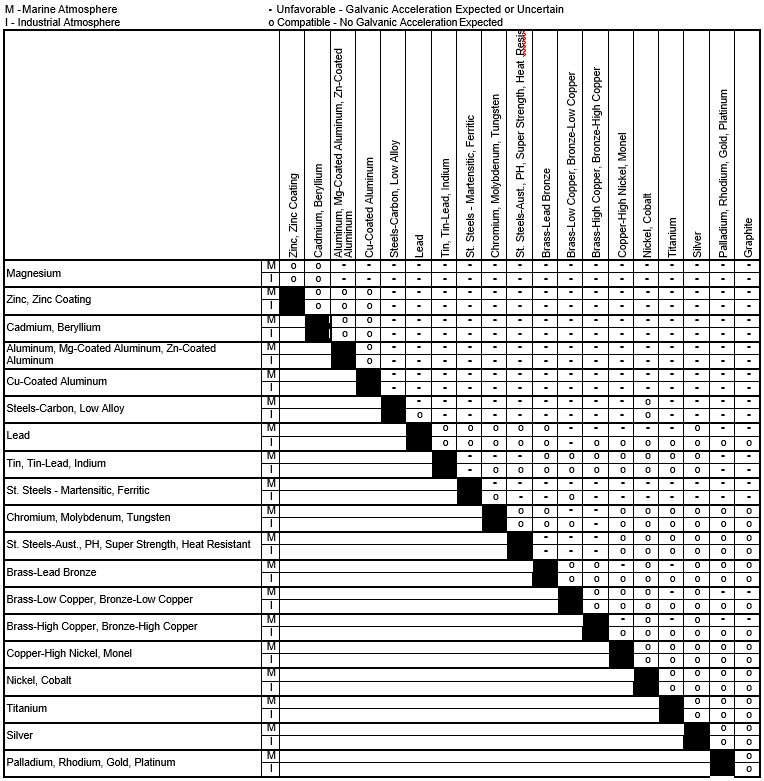

Galvanic corrosion (also called bimetallic corrosion or dissimilar metal corrosion) is an electrochemical process in which one metal corrodes preferentially when it is in electrical contact with another, in the presence of an electrolyte. Web below, we give a brief overview of galvanic corrosion and provide a galvanic corrosion chart to help fabricators and machinists avoid using the wrong metal. When dissimilar metals are used together in the presence of an electrolyte,. Web galvanic corrosion occurs when two different metals or alloys with different nobilities and therefore different electrochemical potentials come into contact with each. Web the following documents provide different points of view regarding the ranking of metals and coatings in practical schemes for preventing galvanic corrosion.

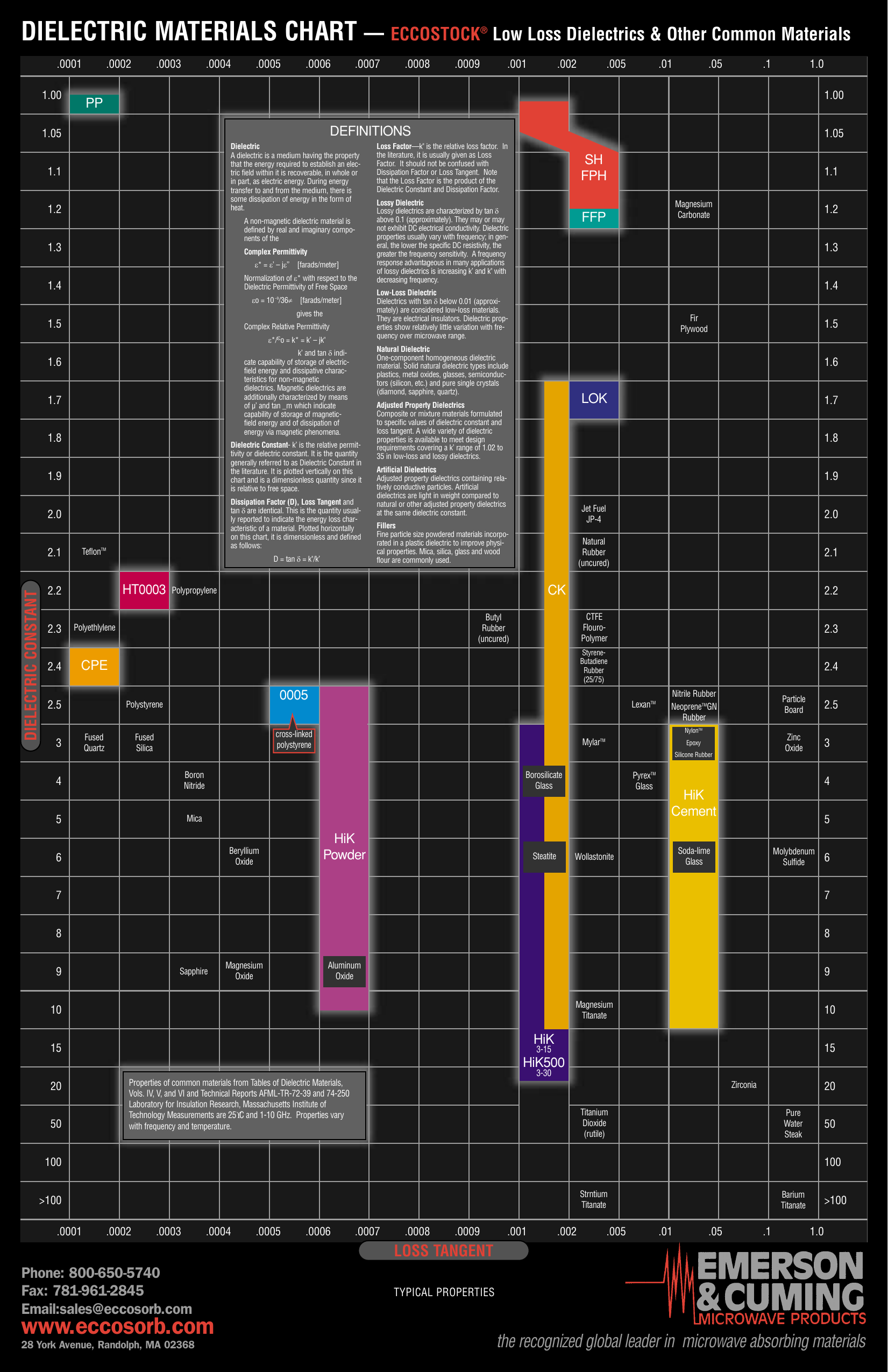

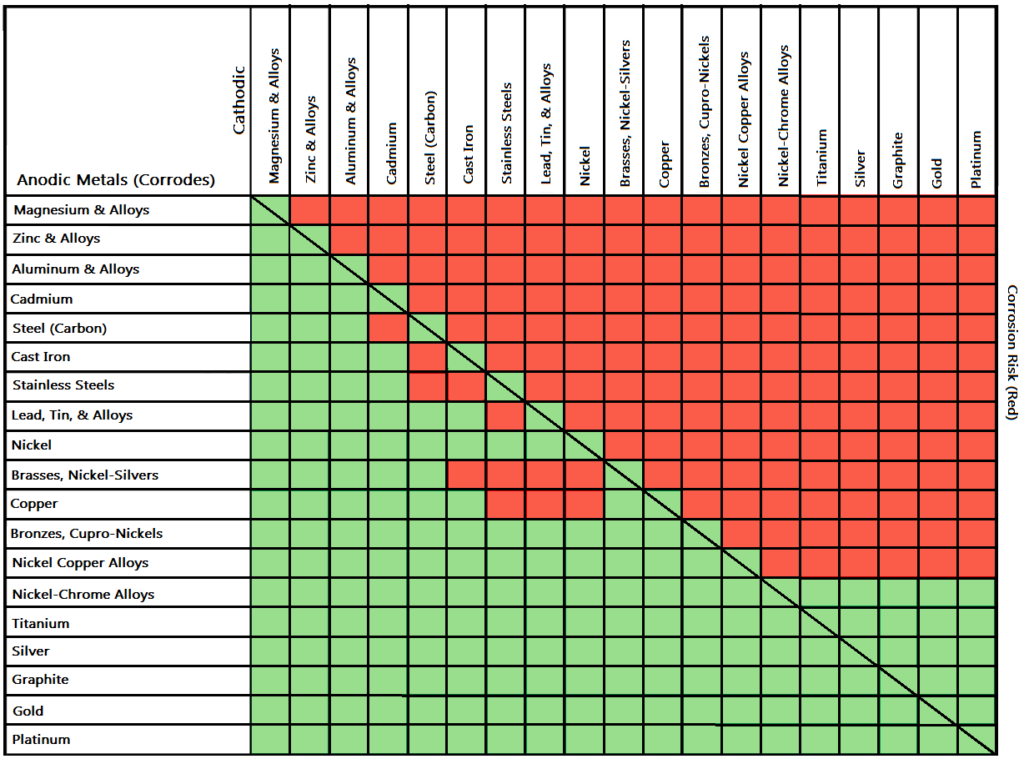

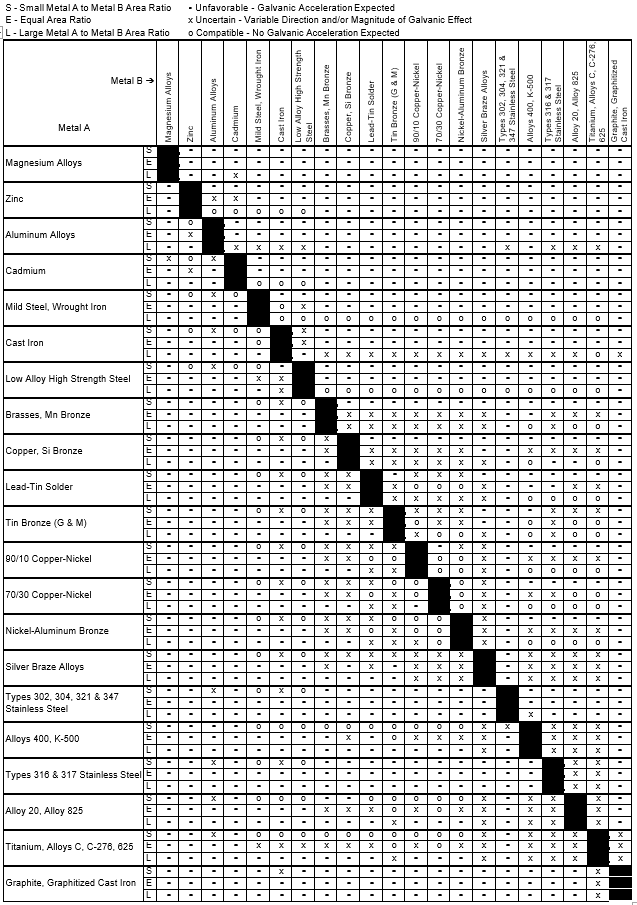

Web the following documents provide different points of view regarding the ranking of metals and coatings in practical schemes for preventing galvanic corrosion. For any combination of dissimilar metals, the metal with the lower number will act. See the chart with anodic, cathodic, and neutral. Web galvanic corrosion is the damage of metal due to an electrochemical reaction between dissimilar metals in contact with an electrolyte. Web find out how different metals will corrode when placed together in an assembly based on their galvanic corrosion potential.

Web galvanic corrosion, also known as bimetallic corrosion or dissimilar metal corrosion, is an electrochemical process that occurs when two different metals are in. Web metals listed on the top of the chart (anodic) will corrode faster than the metals on the bottom of the chart (cathodic). Contact a corrosion specialist to determine the best. Web galvanic corrosion (also called ' dissimilar metal corrosion' or wrongly 'electrolysis') refers to corrosion damage induced when two dissimilar materials are coupled in a corrosive. Web galvanic corrosion is the damage of metal due to an electrochemical reaction between dissimilar metals in contact with an electrolyte. Web galvanic corrosion occurs when two different metals or alloys with different nobilities and therefore different electrochemical potentials come into contact with each. When dissimilar metals are used together in the presence of an electrolyte,. This phenomenon is named after italian ph… See the chart with anodic, cathodic, and neutral. Galvanic corrosion (also called bimetallic corrosion or dissimilar metal corrosion) is an electrochemical process in which one metal corrodes preferentially when it is in electrical contact with another, in the presence of an electrolyte. The alloys near the bottom are cathodic and. The corroded area was machined out and rebuilt with alloy 625 filler metal which is. It includes a chart that shows how different plating materials react to one another with. Web the “galvanic series of metals and alloys” chart above provides a realistic and practical ranking of metallic electrical potentials. Web find out how different metals will corrode when placed together in an assembly based on their galvanic corrosion potential.

Web Galvanic Corrosion Is The Damage Of Metal Due To An Electrochemical Reaction Between Dissimilar Metals In Contact With An Electrolyte.

Web galvanic corrosion undermined the keeper rings, leading to failure and leakage. By eliminating any one of. Web galvanic corrosion occurs when two different metals or alloys with different nobilities and therefore different electrochemical potentials come into contact with each. Web there are three conditions that must exist for galvanic corrosion to occur.

The Alloys Near The Bottom Are Cathodic And.

For any combination of dissimilar metals, the metal with the lower number will act. Web this article examines how dissimilar metals can lead to galvanic corrosion. Web below, we give a brief overview of galvanic corrosion and provide a galvanic corrosion chart to help fabricators and machinists avoid using the wrong metal. The corroded area was machined out and rebuilt with alloy 625 filler metal which is.

See The Chart With Anodic, Cathodic, And Neutral.

The most active metals in the galvanic corrosion chart, like aluminum, zinc,. When dissimilar metals are used together in the presence of an electrolyte,. Web there are two primary types of galvanic cells that cause corrosion: Web find out how different metals will corrode when placed together in an assembly based on their galvanic corrosion potential.

Contact A Corrosion Specialist To Determine The Best.

Web a phenomenon known as galvanic corrosion occurs when dissimilar metals, subjected to the same environment, comprised of a conducting solution, are in direct electrical contact. Web the following documents provide different points of view regarding the ranking of metals and coatings in practical schemes for preventing galvanic corrosion. First there must be two electrochemically dissimilar metals present. Web this slide includes a chart of galvanic corrosion potential between common construction metals.