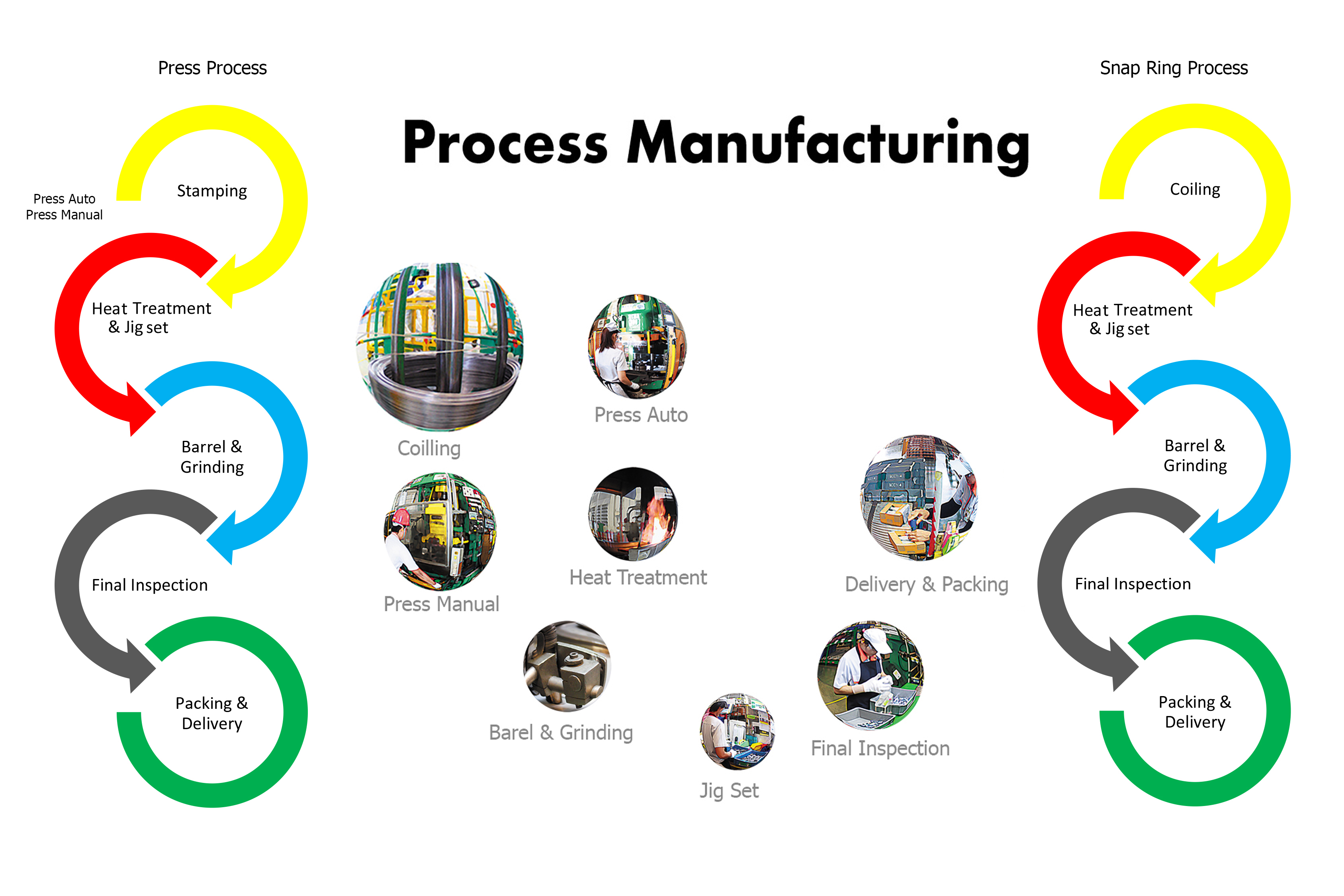

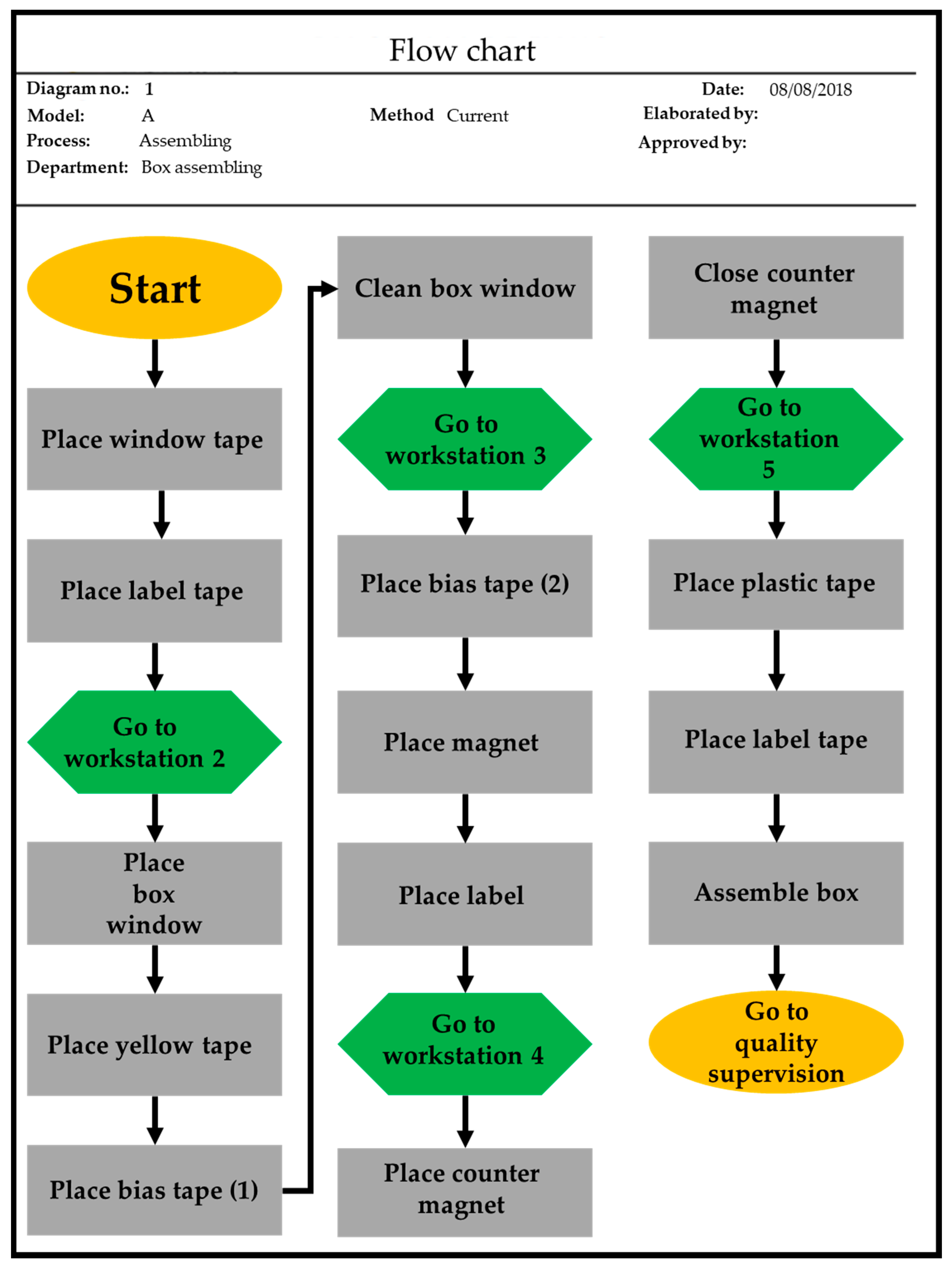

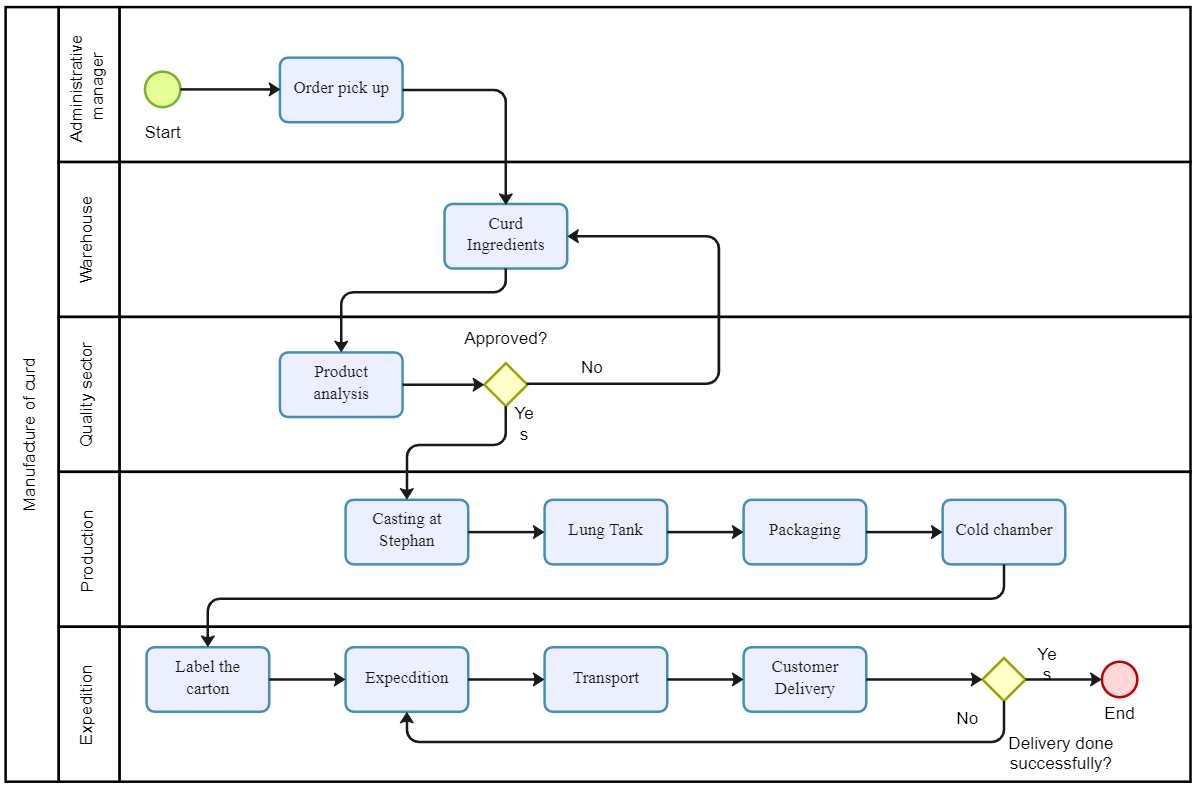

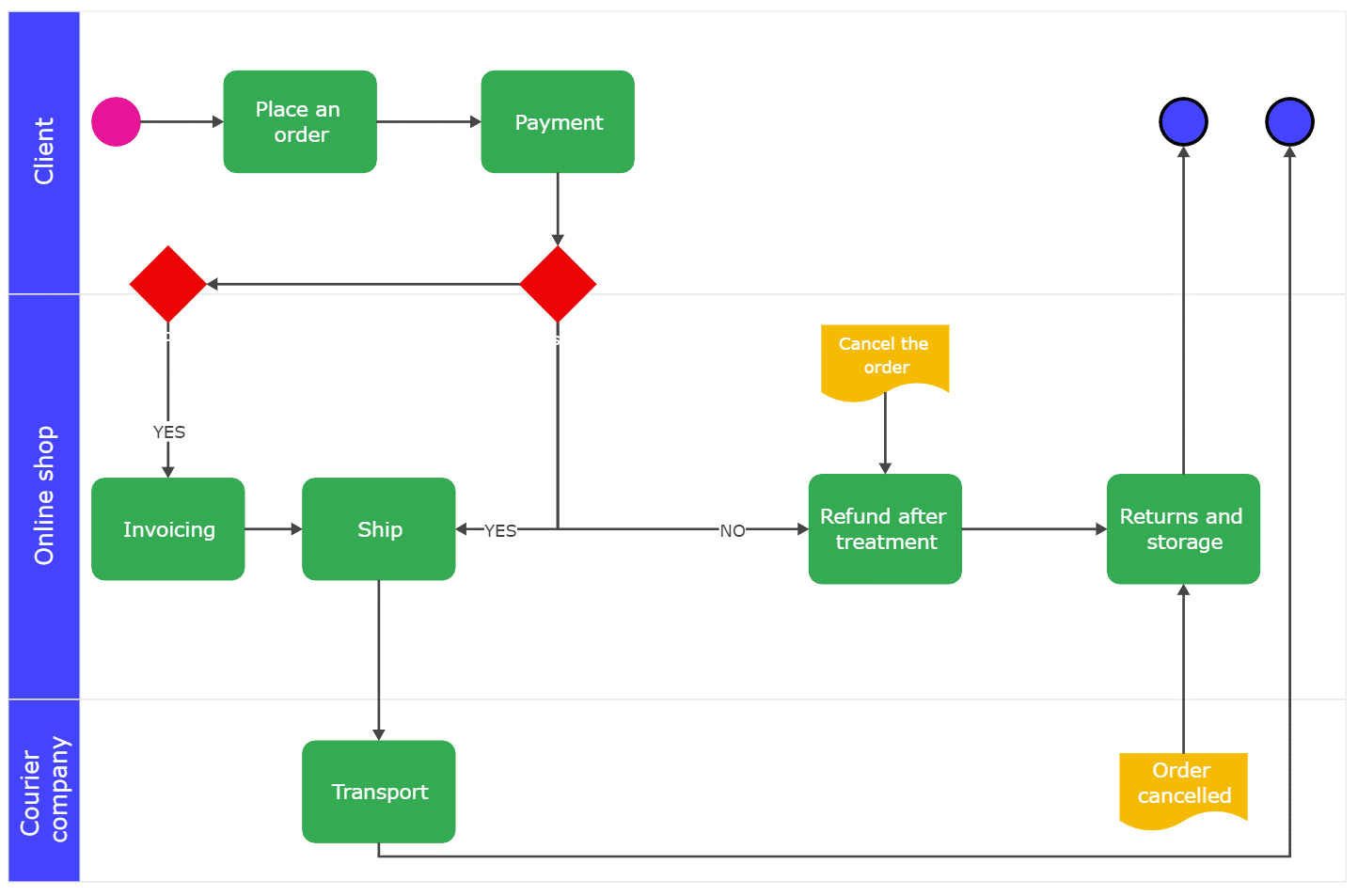

Creating a new product or service. Pfc also known as process flow. Web how to make a process flow diagram. This approach helps minimize losses by assuring better quality. Web a production flowchart is a visualization of an order process from beginning to end.

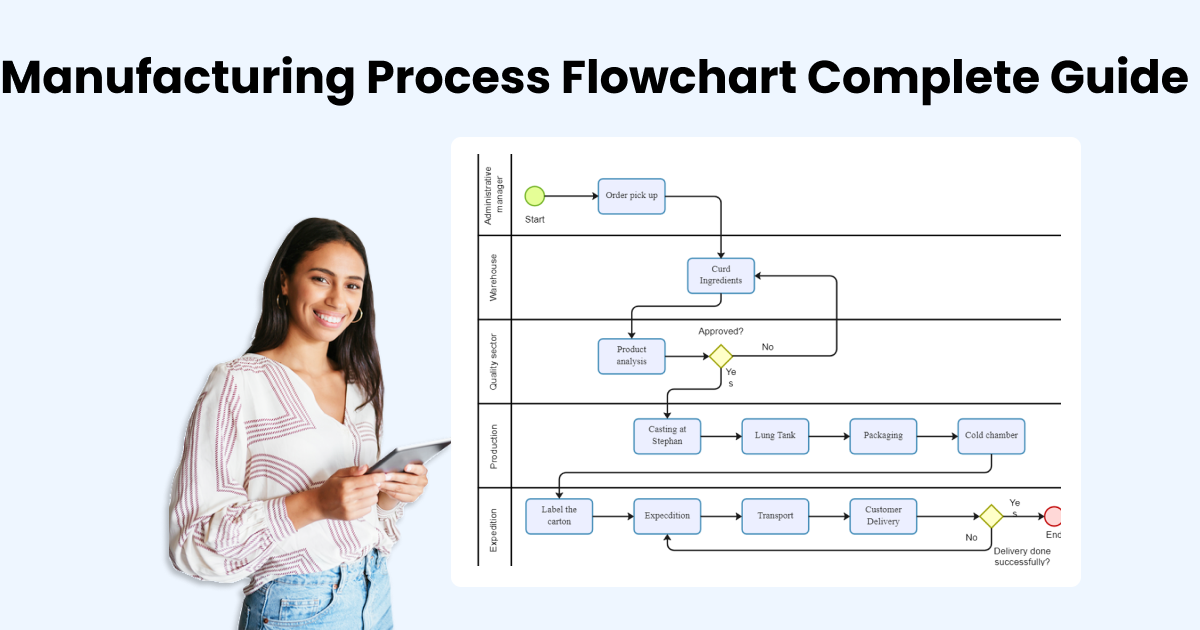

Web check this complete guide to know everything about flowchart, like flowchart types, flowchart symbols, and how to make a flowchart. The process begins with the receipt of raw materials, which are then. So you want to learn flowcharts? It uses symbols and arrows to show the flow. Our production flowchart template allows you to build out and customize your entire.

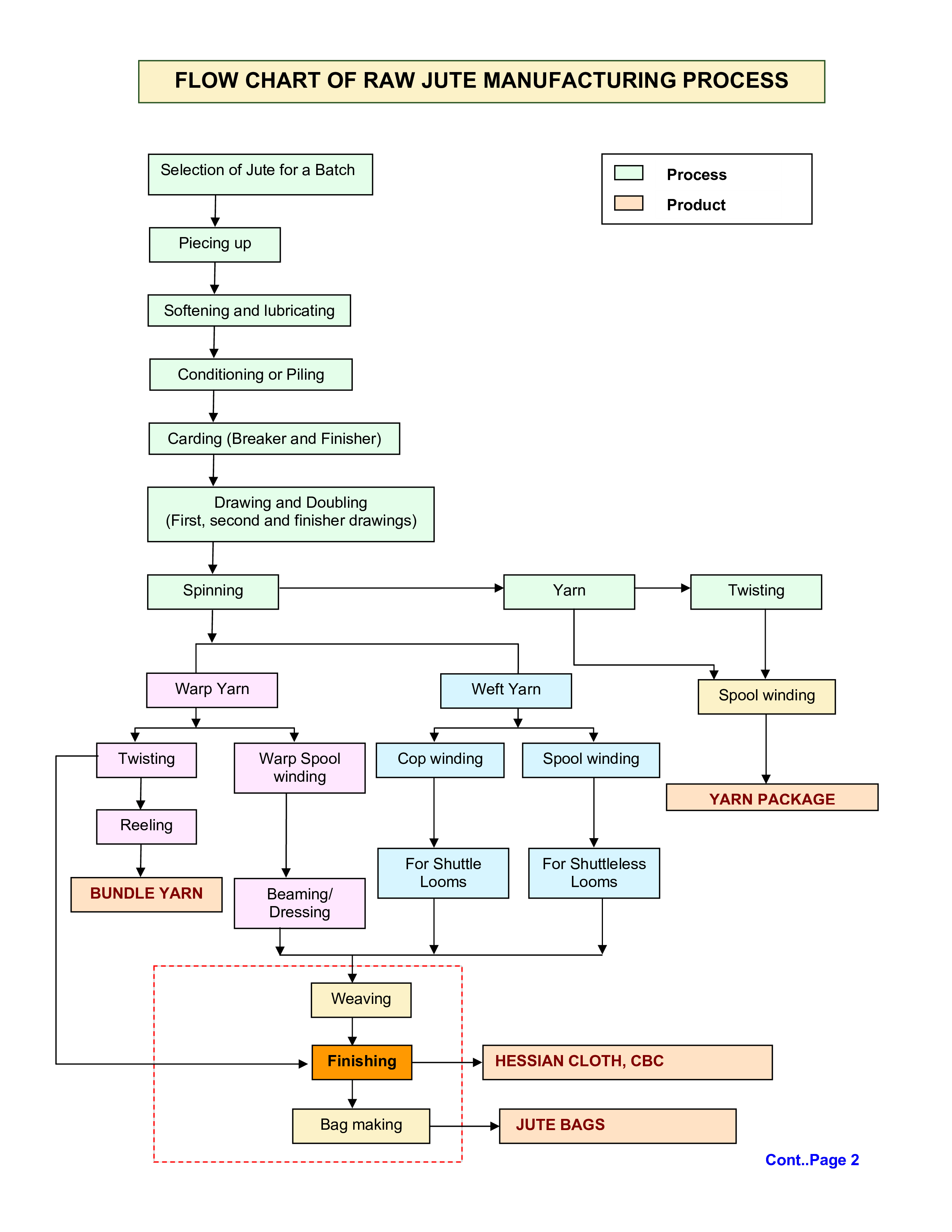

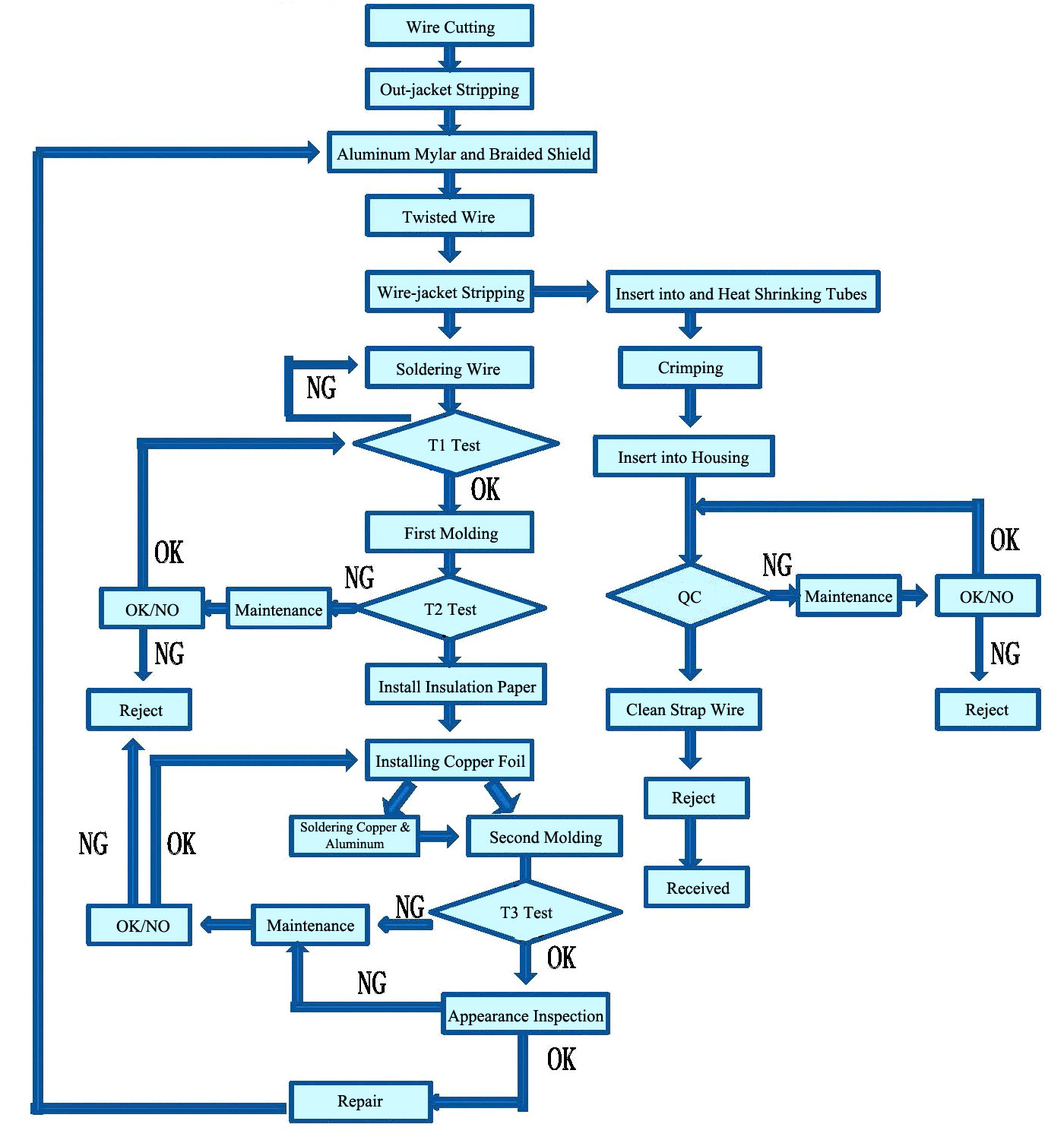

Web a production flowchart is a visualization of an order process from beginning to end. Web a process flow diagram (pfd) is a type of flowchart that illustrates the relationships between major components at an industrial plant. Web this flow chart outlines the process of manufacturing a product from raw materials to finished goods. It uses symbols and arrows to show the flow. It's most often used in chemical.

Web by following a flowchart, manufacturers can identify potential bottlenecks or delays in the process and make adjustments to improve efficiency. Web this manufacturing flow template can help you: Web how to make a process flow diagram. Our production flowchart template allows you to build out and customize your entire. These charts facilitate better communication among team members by providing a shared understanding of the process and its stages. Web check this complete guide to know everything about flowchart, like flowchart types, flowchart symbols, and how to make a flowchart. The process begins with the receipt of raw materials, which are then. Web a production flowchart is a visualization of an order process from beginning to end. Outlining steps and decisions in a process. Web the primary purpose of a manufacturing flowchart is to communicate the process stages, from raw materials to finished products, in a clear and comprehensible manner. It's most often used in chemical. Web create one using a template. Along with the ability to work in almost any scenario, flow charts. Web a process flow chart, also known as a process map or process flow diagram, is a visual representation of a process in a business. Creating a process flow diagram is a structured approach to visualizing and understanding the steps and flow of a process.

Web A Process Flow Diagram (Pfd) Is A Type Of Flowchart That Illustrates The Relationships Between Major Components At An Industrial Plant.

Web the primary purpose of a manufacturing flowchart is to communicate the process stages, from raw materials to finished products, in a clear and comprehensible manner. It shows the stages, equipment used and quality control checks where you’ll. Majority of printed circuit boards are manufactured by applying a layer of copper over the entire surface of the pcb substrate. Along with the ability to work in almost any scenario, flow charts.

Web A Production Flowchart Is A Visualization Of An Order Process From Beginning To End.

At first glance, you can see the process map for a product family “shaft cty” with an annual. It uses symbols and arrows to show the flow. Web this flow chart outlines the process of manufacturing a product from raw materials to finished goods. So you want to learn flowcharts?

Our Production Flowchart Template Allows You To Build Out And Customize Your Entire.

Web a process flow chart (pfc) in manufacturing is a diagram of the separate steps of a operations/process in sequential order. Web a process flow chart is an effective tool for teams, project managers, and stakeholders to document and communicate a process and ensure everyone involved understands their. This allows anyone to view the flowchart and logically follow the process from beginning to end. Web this manufacturing flow template can help you:

A Good Visual Of A Manufacturing.

Web a flowchart is a picture of the separate steps of a process in sequential order. Web by following a flowchart, manufacturers can identify potential bottlenecks or delays in the process and make adjustments to improve efficiency. Web create one using a template. The process begins with the receipt of raw materials, which are then.