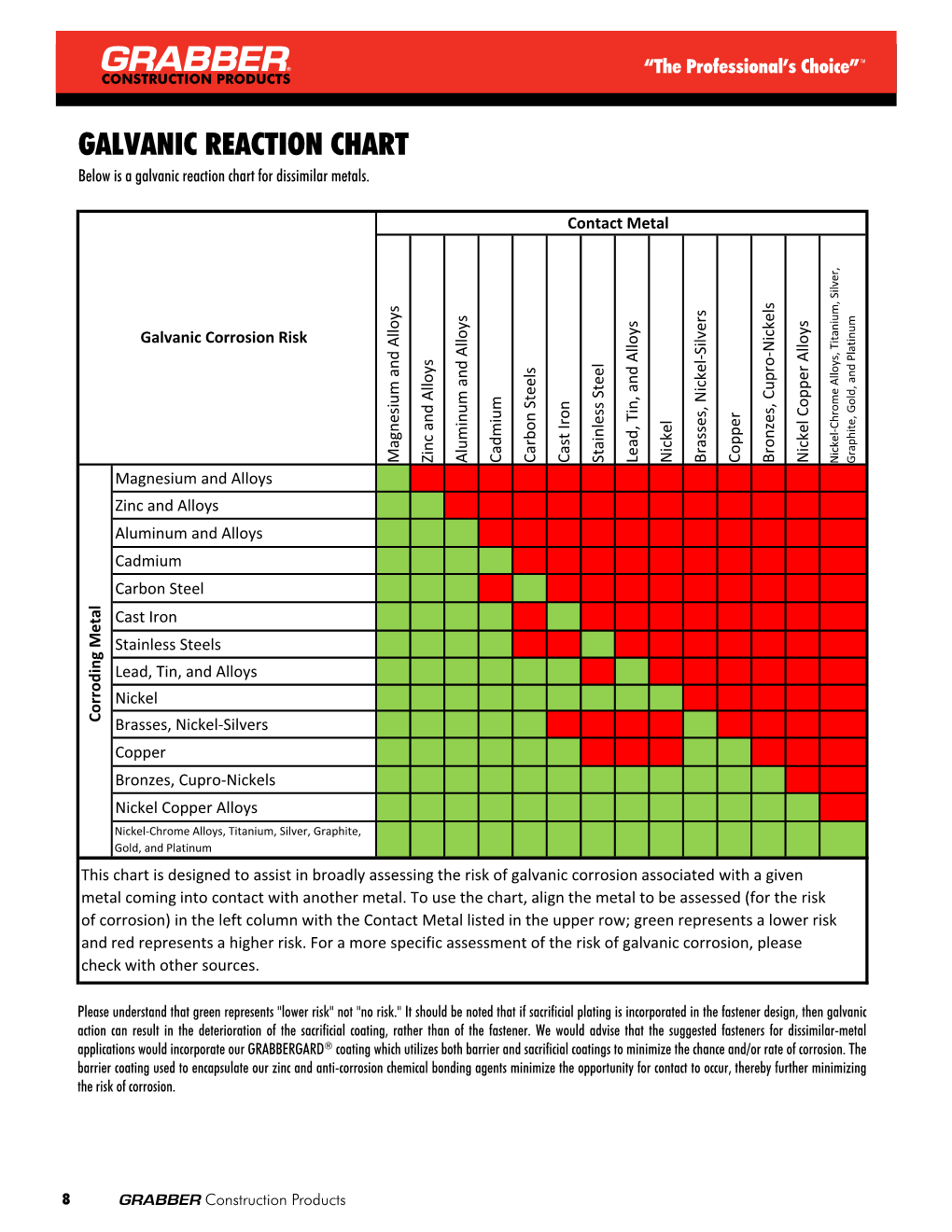

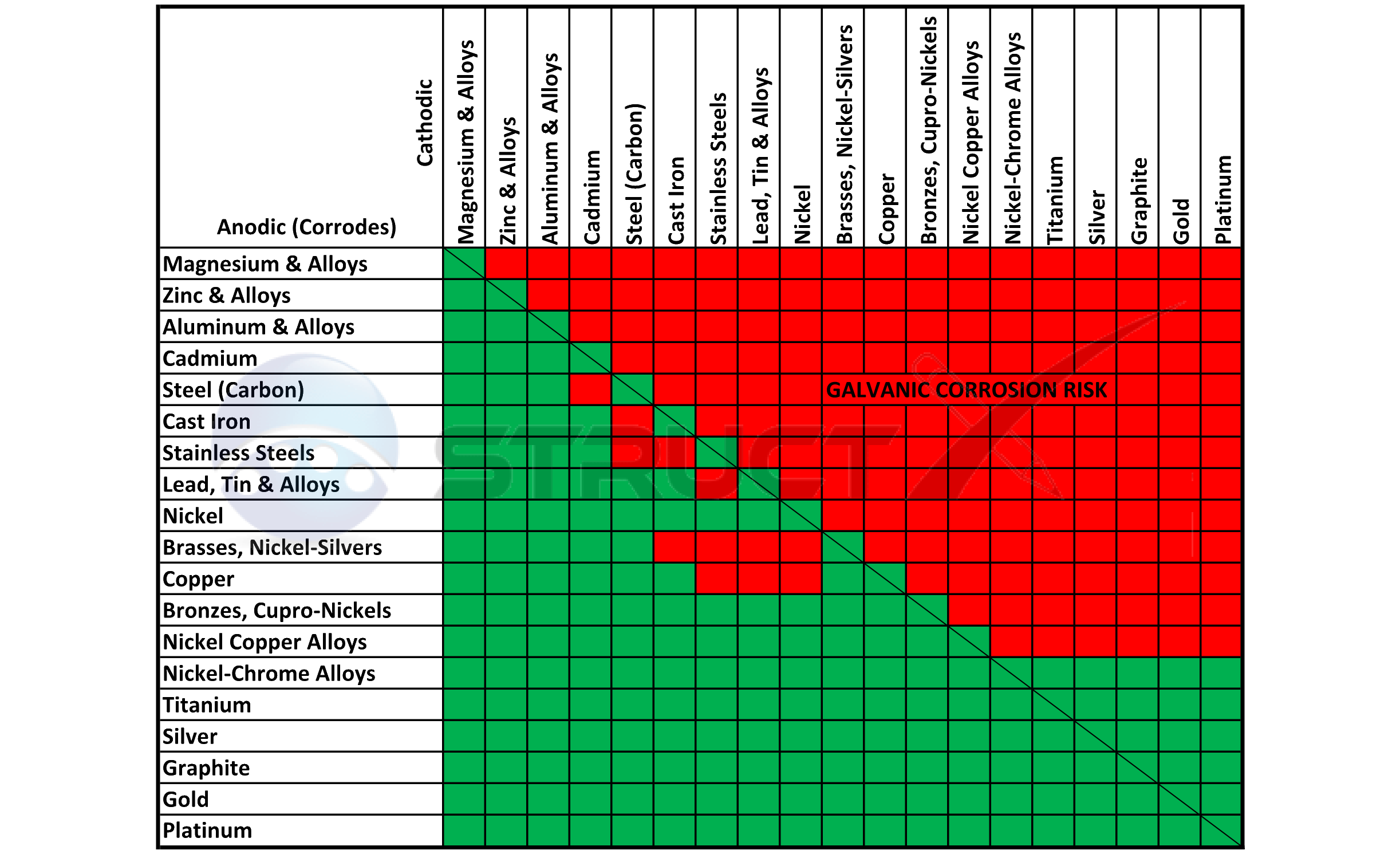

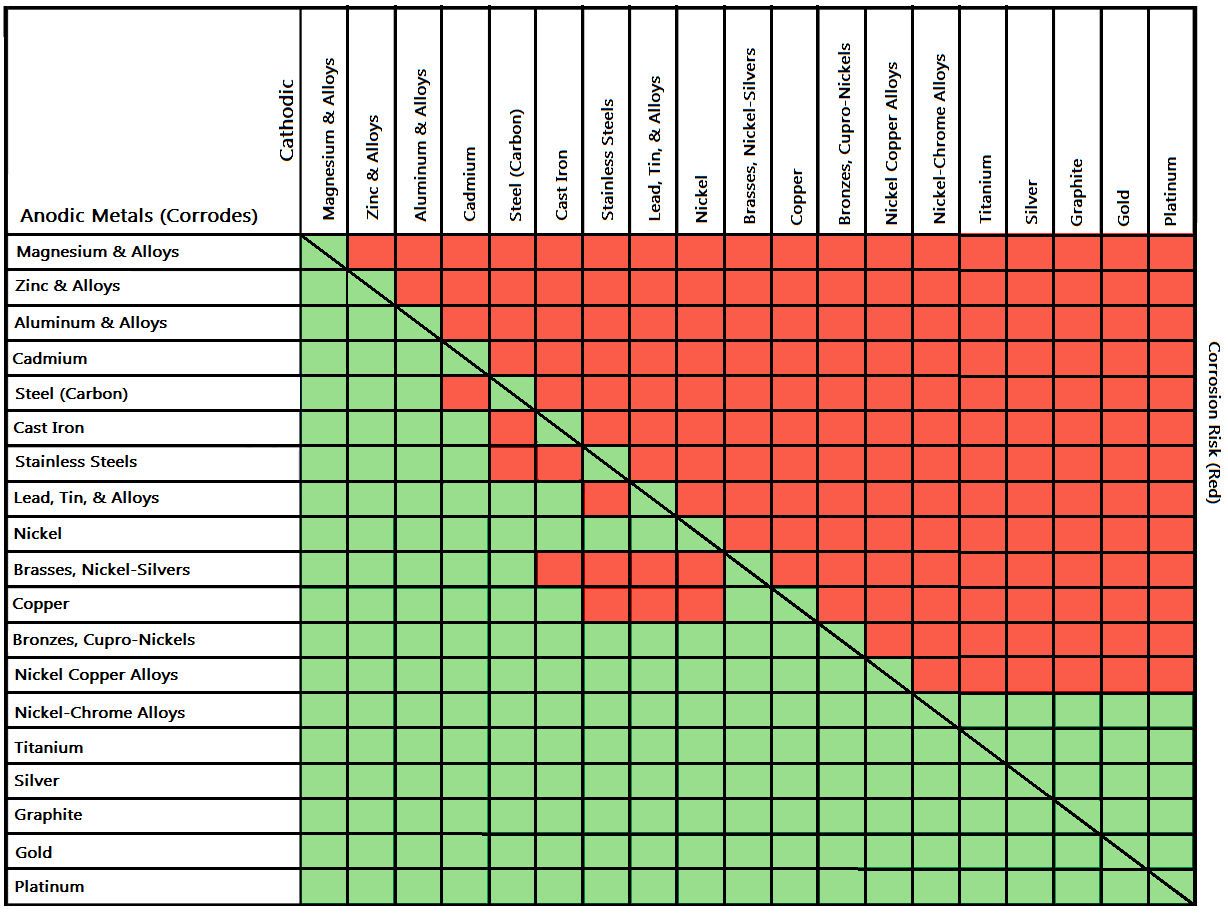

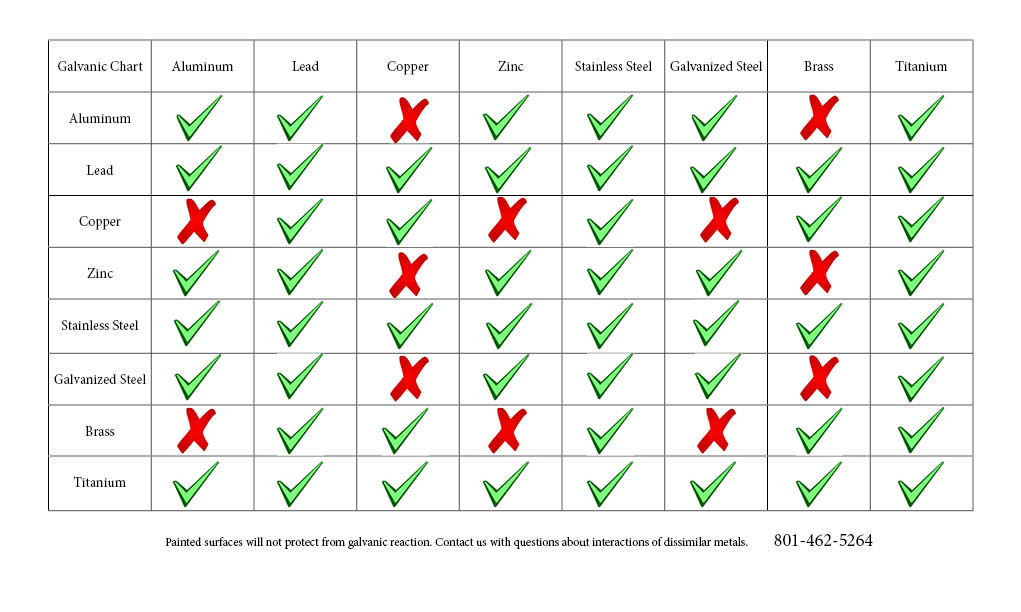

Web the galvanic corrosion table ranks metals from the most “active” to the least active. This chart is designed to assist in broadly assessing the risk of galvanic corrosion associated with a given metal coming. See a chart of metals and their electrochemical potentials, and examples. The most active metals in the galvanic corrosion chart, like aluminum, zinc, or. Web to minimize galvanic corrosion, select fasteners based on their material compatibility with the substrates.

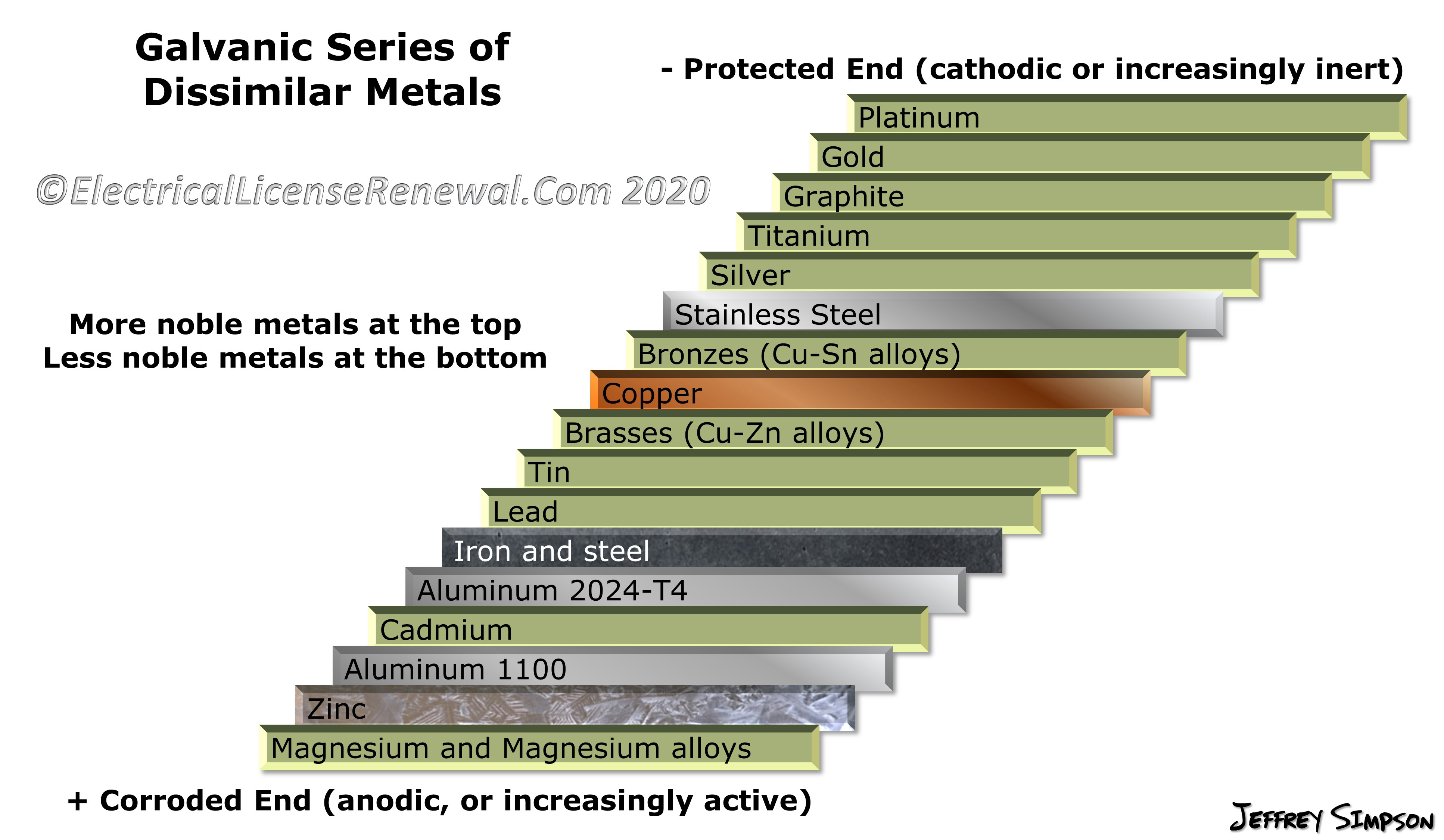

Web a chart depicting the galvanic series for some common metals in a frequently encountered conducting solution, seawater, is included in figure 1. See a chart of metals and their electrochemical potentials, and examples. Web below is a galvanic reaction chart for dissimilar metals. Web the galvanic corrosion table ranks metals from the most “active” to the least active. Web galvanic corrosion (also called bimetallic corrosion or dissimilar metal corrosion) is an electrochemical process in which one metal corrodes preferentially when it is in electrical.

So, for example, choosing zinc on zinc would have the lowest risk for. Web below is a galvanic reaction chart for dissimilar metals. Web the galvanic corrosion chart, also referred to as the galvanic series or compatibility chart, is a valuable tool used to assess the compatibility of different metal. Web below, we give a brief overview of galvanic corrosion and provide a galvanic corrosion chart to help fabricators and machinists avoid using the wrong metal. Web the increased corrosion of the anode is called “galvanic corrosion.” galvanic corrosion is sometimes used to extend the life of materials (i.e.

The following galvanic table lists metals in the order of their relative activity in seawater environment. Web below is a galvanic reaction chart for dissimilar metals. Web there are four elements necessary for corrosion to occur in a galvanic cell: Web the galvanic corrosion table ranks metals from the most “active” to the least active. Web the increased corrosion of the anode is called “galvanic corrosion.” galvanic corrosion is sometimes used to extend the life of materials (i.e. Web galvanic corrosion (also called bimetallic corrosion or dissimilar metal corrosion) is an electrochemical process in which one metal corrodes preferentially when it is in electrical. Web galvanic corrosion (some times called dissimilar metal corrosion) is the process by which the materials in contact with each other oxidizes or corrodes. The most active metals in the galvanic corrosion chart, like aluminum, zinc, or. Web learn what galvanic action is, how it occurs, and how to prevent it in construction. Web the galvanic corrosion chart, also referred to as the galvanic series or compatibility chart, is a valuable tool used to assess the compatibility of different metal. Web view this chart of galvanic compatibility. We consider two metals compatible if their emf. This can help you in the selection of the best. This chart is designed to assist in broadly assessing the risk of galvanic corrosion associated with a given metal coming. The list begins with the more.

Web Galvanic Corrosion (Some Times Called Dissimilar Metal Corrosion) Is The Process By Which The Materials In Contact With Each Other Oxidizes Or Corrodes.

Web the galvanic corrosion chart, also referred to as the galvanic series or compatibility chart, is a valuable tool used to assess the compatibility of different metal. This chart is designed to assist in broadly assessing the risk of galvanic corrosion associated with a given metal coming. The closer together the material are on the chart to the right, the less. The below galvanic corrion chart or anodic index table shows anodic index for different materials.

Web A Chart Depicting The Galvanic Series For Some Common Metals In A Frequently Encountered Conducting Solution, Seawater, Is Included In Figure 1.

The following galvanic table lists metals in the order of their relative activity in seawater environment. Zinc coatings on carbon steel and. Web however, you can completely avoid galvanic corrosion by choosing matching metal anchors. Though the order of metals in a.

Web To Minimize Galvanic Corrosion, Select Fasteners Based On Their Material Compatibility With The Substrates.

We consider two metals compatible if their emf. Web view this chart of galvanic compatibility. This chart is designed to assist in broadly assessing the risk of galvanic corrosion associated with a given metal coming. Web learn what galvanic action is, how it occurs, and how to prevent it in construction.

Web Galvanic Corrosion (Also Called Bimetallic Corrosion Or Dissimilar Metal Corrosion) Is An Electrochemical Process In Which One Metal Corrodes Preferentially When It Is In Electrical.

See a chart of metals and their electrochemical potentials, and examples. The most active metals in the galvanic corrosion chart, like aluminum, zinc, or. So, for example, choosing zinc on zinc would have the lowest risk for. Web there are four elements necessary for corrosion to occur in a galvanic cell: