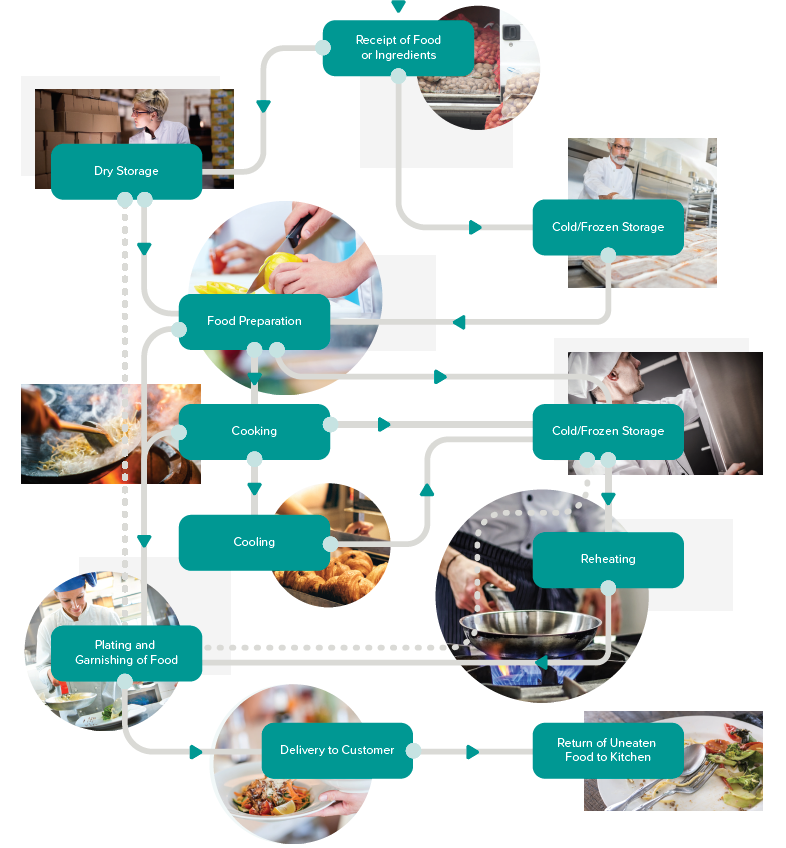

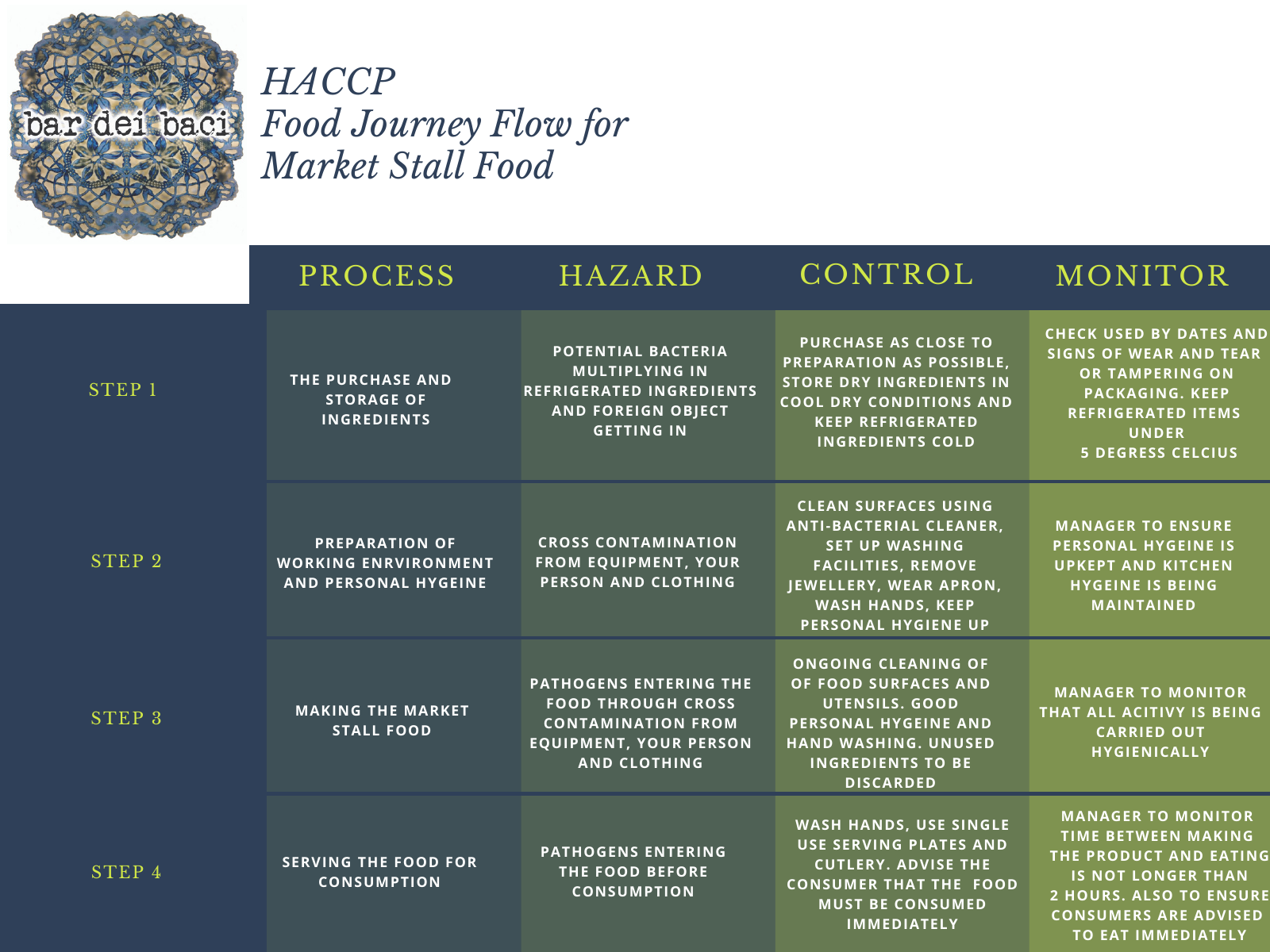

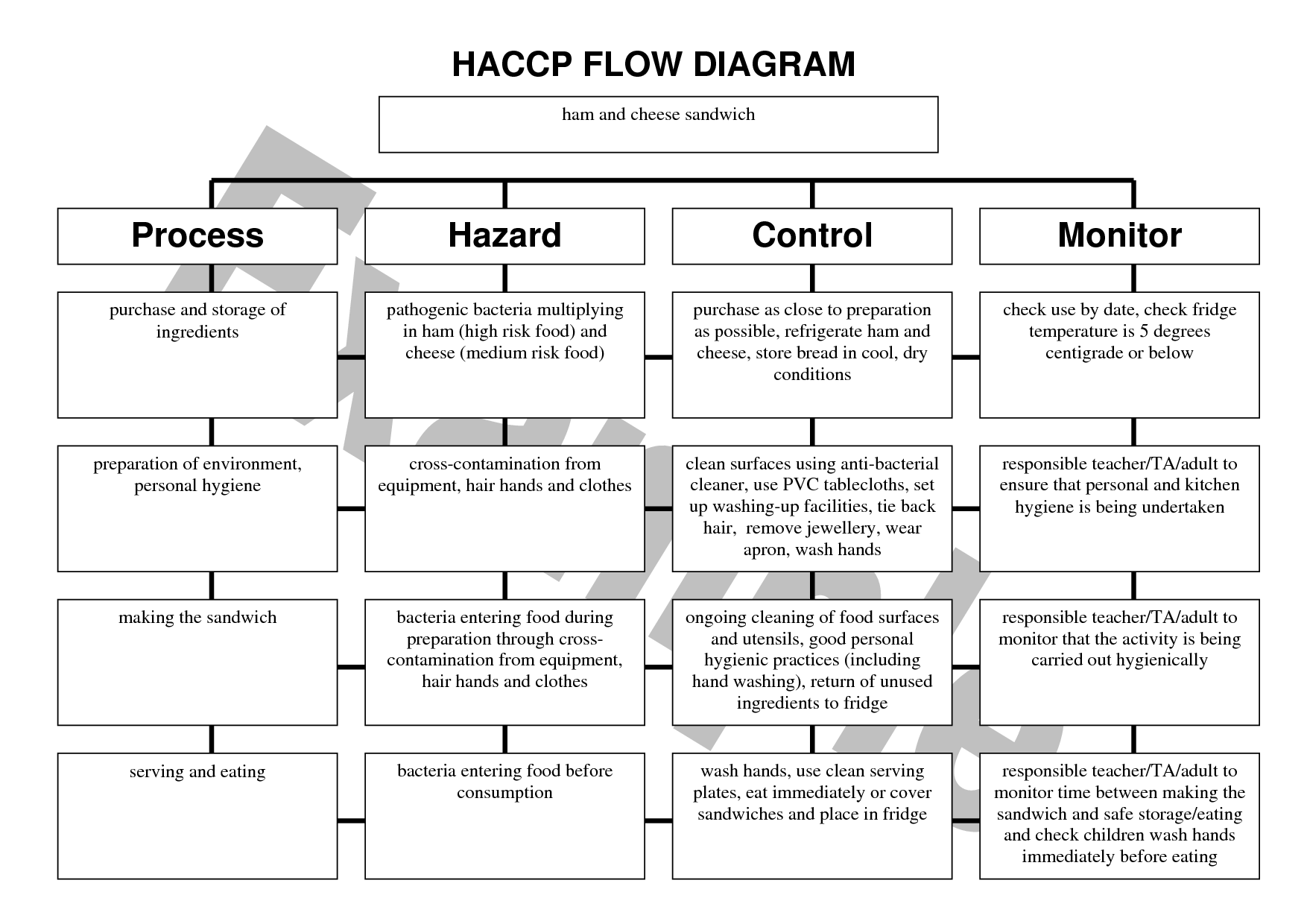

Web a haccp flow chart represents the flow of food materials in your food business starting from receiving any raw material to serving your finished products. Conduct a hazard analysis (principle 1) determine critical control points (ccps) (principle 2) establish critical limits (principle 3) establish monitoring procedures. A flow diagram should include all the steps to produce a specific food product, and it should include all inputs, including ingredients and contact materials, water and air, if relevant. Web the hazard analysis will help you determine which steps in your commodity flow are critical in protecting consumers. Haccp food safety system requires a detailed and comprehensive food flow chart to properly identify the associated hazards in your manufacturing process.

The accuracy of the flow diagram is critical in conducting a hazard analysis. Web the hazard analysis will help you determine which steps in your commodity flow are critical in protecting consumers. (see principle 1 for more information.) document hazard type, likelihood, and control methods on a hazard analysis worksheet. Web foodready food safety software has a haccp builder and customizable haccp templates that make creating your haccp plan flow chart and associated logs and documents much simpler and easier than using a paper system. Web a haccp flow chart represents the flow of food materials in your food business starting from receiving the raw materials to serving your finished products.

Web a haccp flow chart represents the flow of food materials in your food business starting from receiving the raw materials to serving your finished products. Haccp food safety system requires a detailed and comprehensive food flow chart to properly identify the associated hazards in your manufacturing process. Flow diagram and worksheets are recommended in documenting the hazard analysis and final haccp plan. A flow diagram should include all the steps to produce a specific food product, and it should include all inputs, including ingredients and contact materials, water and air, if relevant. Haccp food safety system requires a detailed and comprehensive food flow chart to properly identify the associated hazards in your manufacturing process.

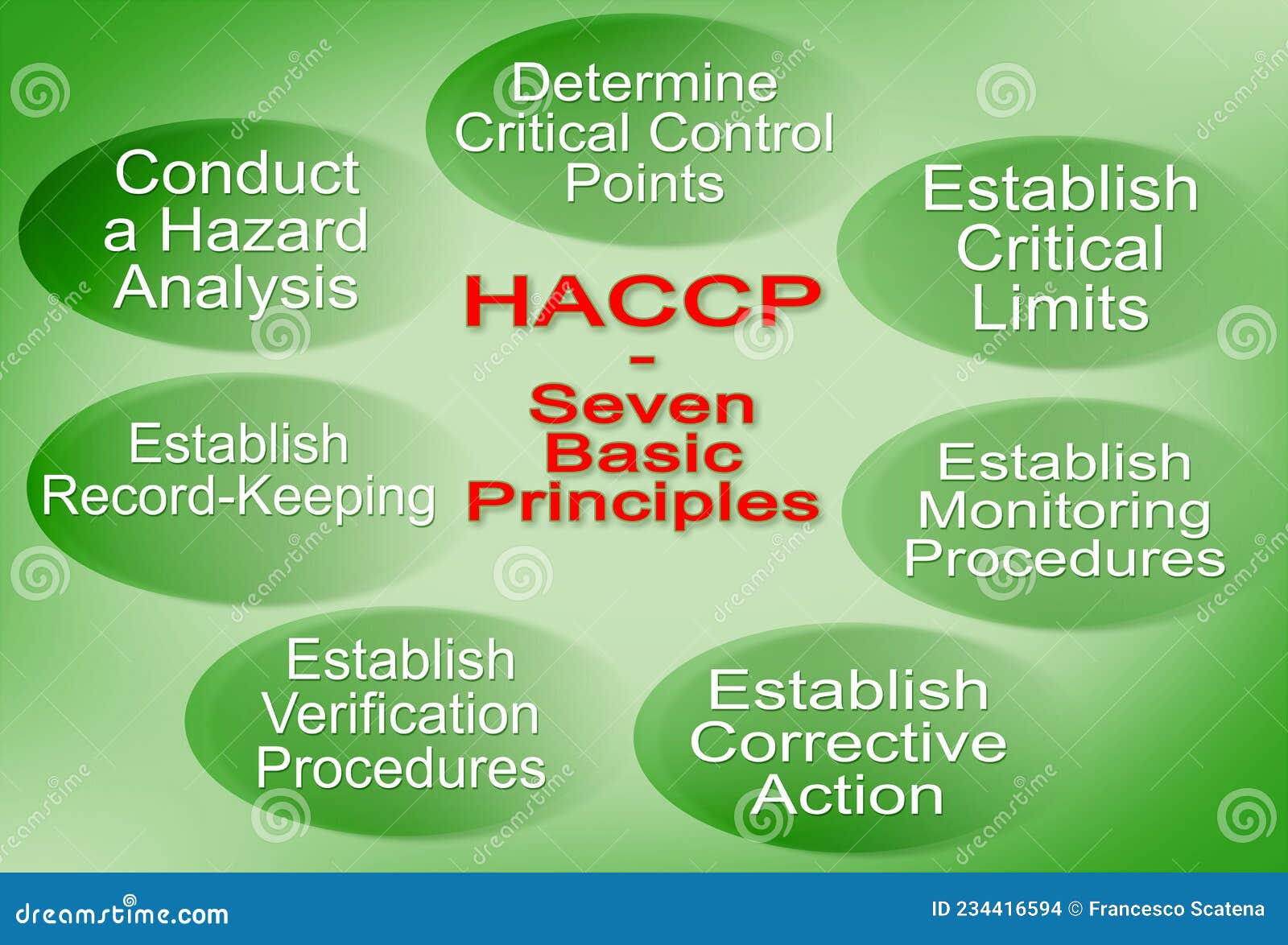

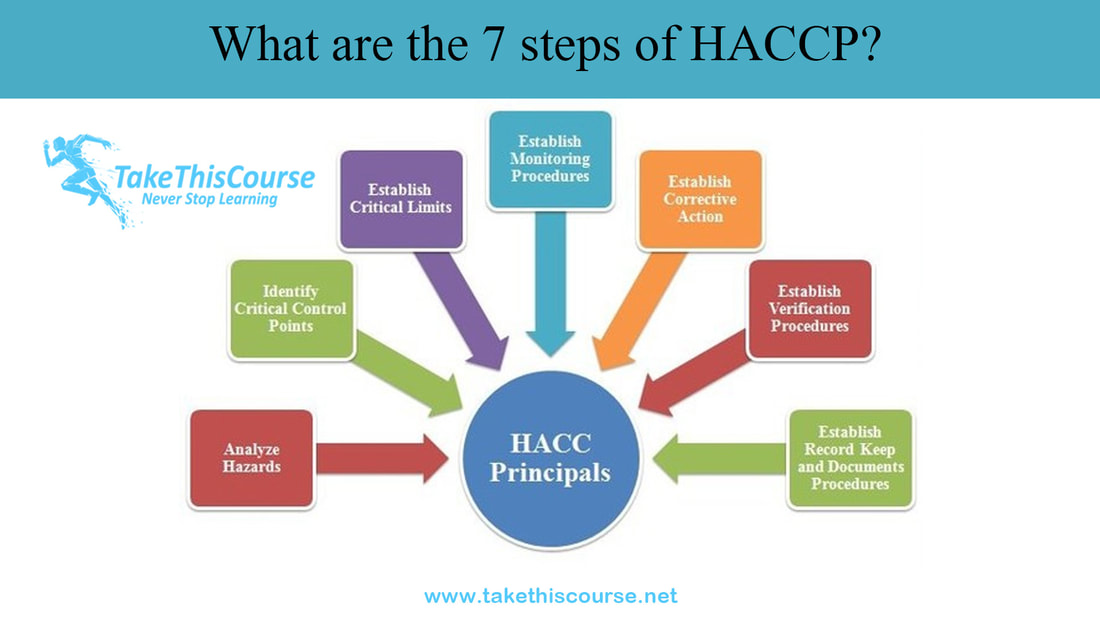

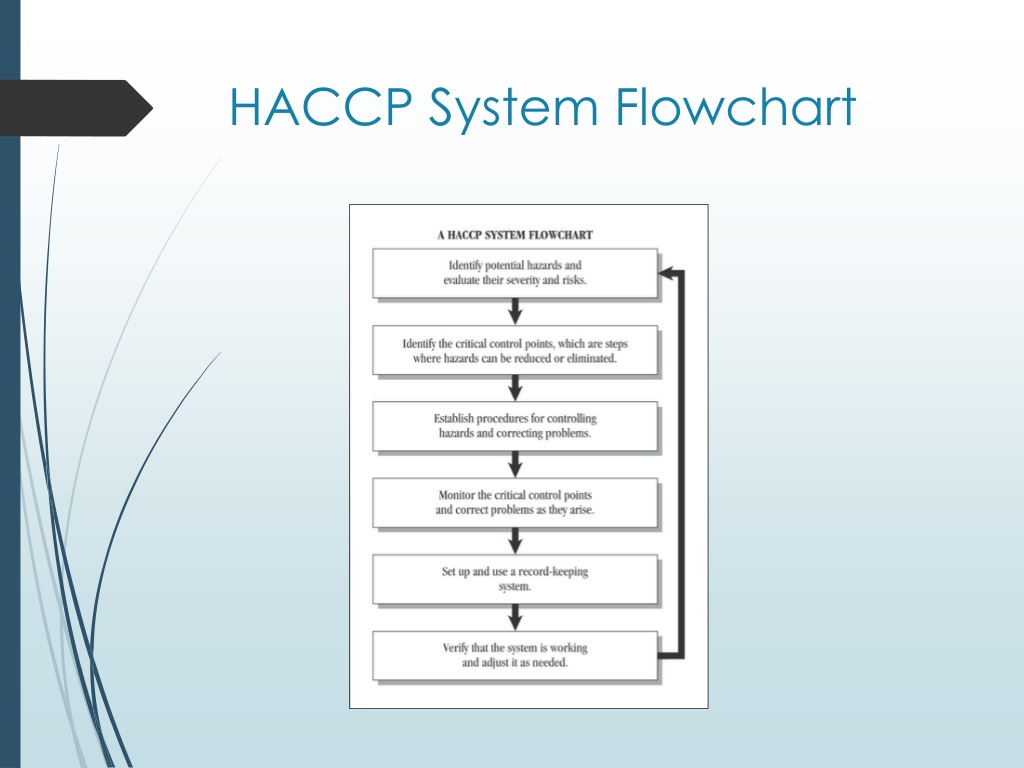

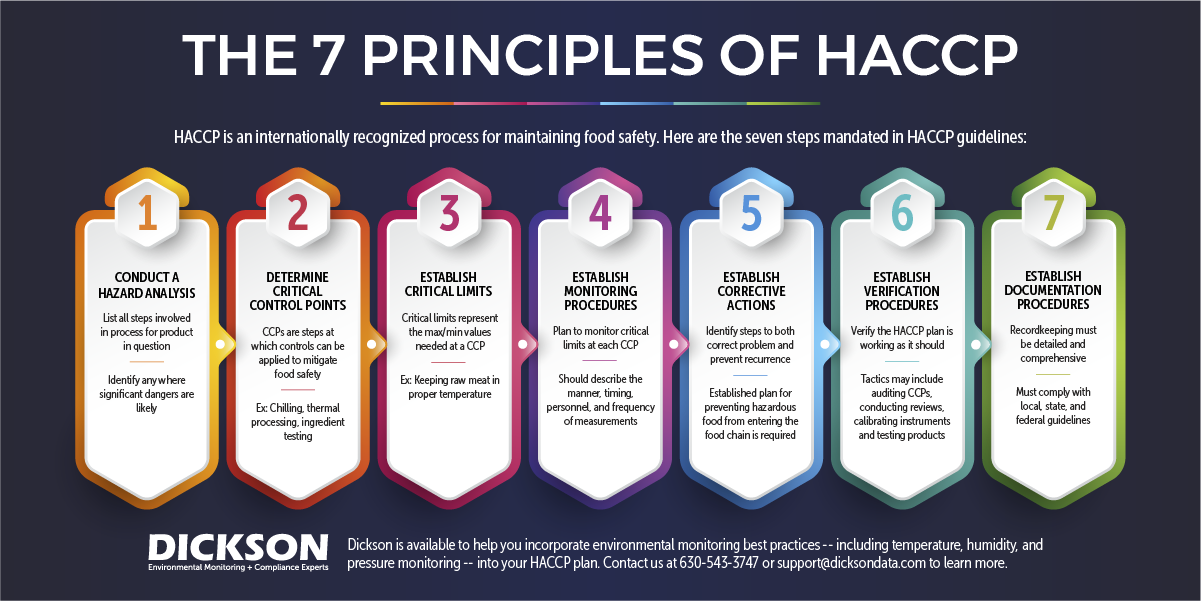

Haccp food safety system requires a detailed and comprehensive food flow chart to properly identify the associated hazards in your manufacturing process. Web foodready food safety software has a haccp builder and customizable haccp templates that make creating your haccp plan flow chart and associated logs and documents much simpler and easier than using a paper system. Web a haccp flow chart represents the flow of food materials in your food business starting from receiving any raw material to serving your finished products. Flow diagram and worksheets are recommended in documenting the hazard analysis and final haccp plan. Web this guidebook for the preparation of haccp plans provides information that may be useful to establishments when developing plans specific to their food production processes and when implementing a food safety system. Web verify the flow diagram. Learn how to implement a haccp plan in this article. Web a haccp flow chart represents the flow of food materials in your food business starting from receiving the raw materials to serving your finished products. In this article, we will be discussing the steps of writing a haccp plan. The accuracy of the flow diagram is critical in conducting a hazard analysis. Haccp food safety system requires a detailed and comprehensive food flow chart to properly identify the associated hazards in your manufacturing process. Fsis developed generic haccp models for each process category which establishments can reference when developing their. A flow diagram should include all the steps to produce a specific food product, and it should include all inputs, including ingredients and contact materials, water and air, if relevant. Web haccp flow process charts are a pictorial representation showing the steps that raw materials go through to become a finished food product. Conduct a hazard analysis (principle 1) determine critical control points (ccps) (principle 2) establish critical limits (principle 3) establish monitoring procedures.

Web A Haccp Flow Chart Represents The Flow Of Food Materials In Your Food Business Starting From Receiving Any Raw Material To Serving Your Finished Products.

Web a haccp flow chart represents the flow of food materials in your food business starting from receiving the raw materials to serving your finished products. In this article, we will be discussing the steps of writing a haccp plan. Web this guidebook for the preparation of haccp plans provides information that may be useful to establishments when developing plans specific to their food production processes and when implementing a food safety system. Conclude the inspection with recommendations and digital signatures.

A Flow Diagram Should Include All The Steps To Produce A Specific Food Product, And It Should Include All Inputs, Including Ingredients And Contact Materials, Water And Air, If Relevant.

Web foodready food safety software has a haccp builder and customizable haccp templates that make creating your haccp plan flow chart and associated logs and documents much simpler and easier than using a paper system. Web the hazard analysis will help you determine which steps in your commodity flow are critical in protecting consumers. Haccp food safety system requires a detailed and comprehensive food flow chart to properly identify the associated hazards in your manufacturing process. Web verify the flow diagram.

Haccp Food Safety System Requires A Detailed And Comprehensive Food Flow Chart To Properly Identify The Associated Hazards In Your Manufacturing Process.

Flow diagram and worksheets are recommended in documenting the hazard analysis and final haccp plan. Fsis developed generic haccp models for each process category which establishments can reference when developing their. (see principle 1 for more information.) document hazard type, likelihood, and control methods on a hazard analysis worksheet. Web determine ccp and establish its critical limits and monitoring procedures.

Web Haccp Flow Process Charts Are A Pictorial Representation Showing The Steps That Raw Materials Go Through To Become A Finished Food Product.

The accuracy of the flow diagram is critical in conducting a hazard analysis. Learn how to implement a haccp plan in this article. Conduct a hazard analysis (principle 1) determine critical control points (ccps) (principle 2) establish critical limits (principle 3) establish monitoring procedures.

![26 Fantastic Flow Chart Templates [Word, Excel, Power Point]](https://templatelab.com/wp-content/uploads/2021/08/HACCP-Flow-Chart-scaled.jpg)