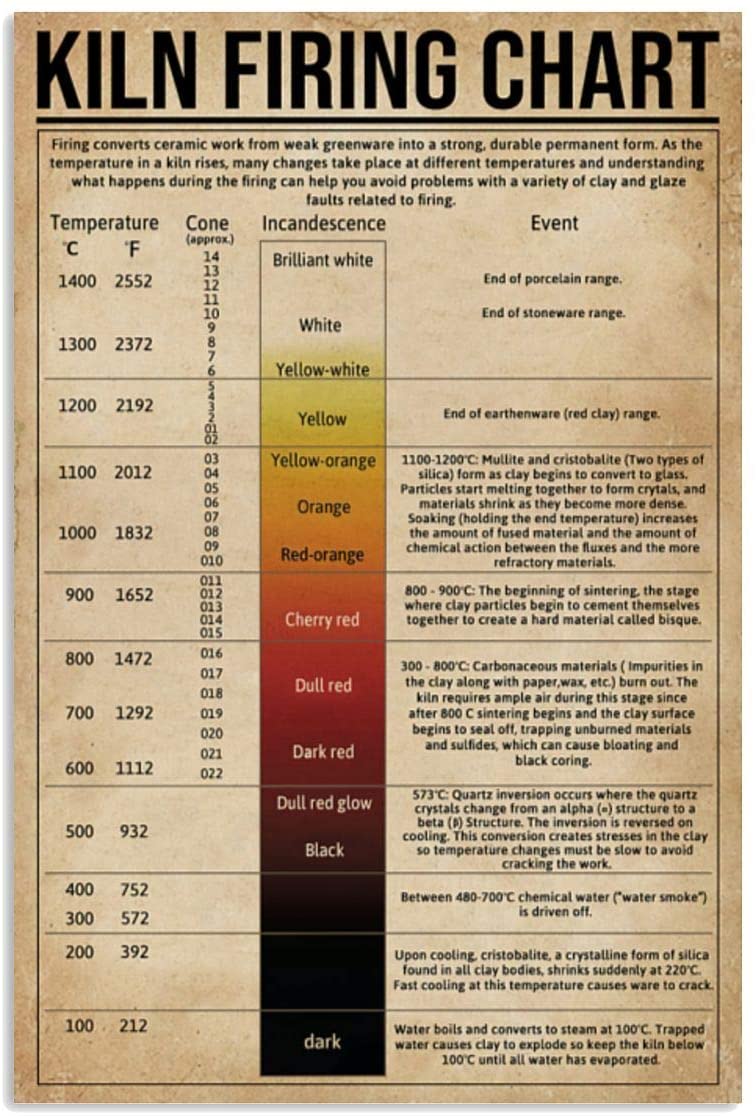

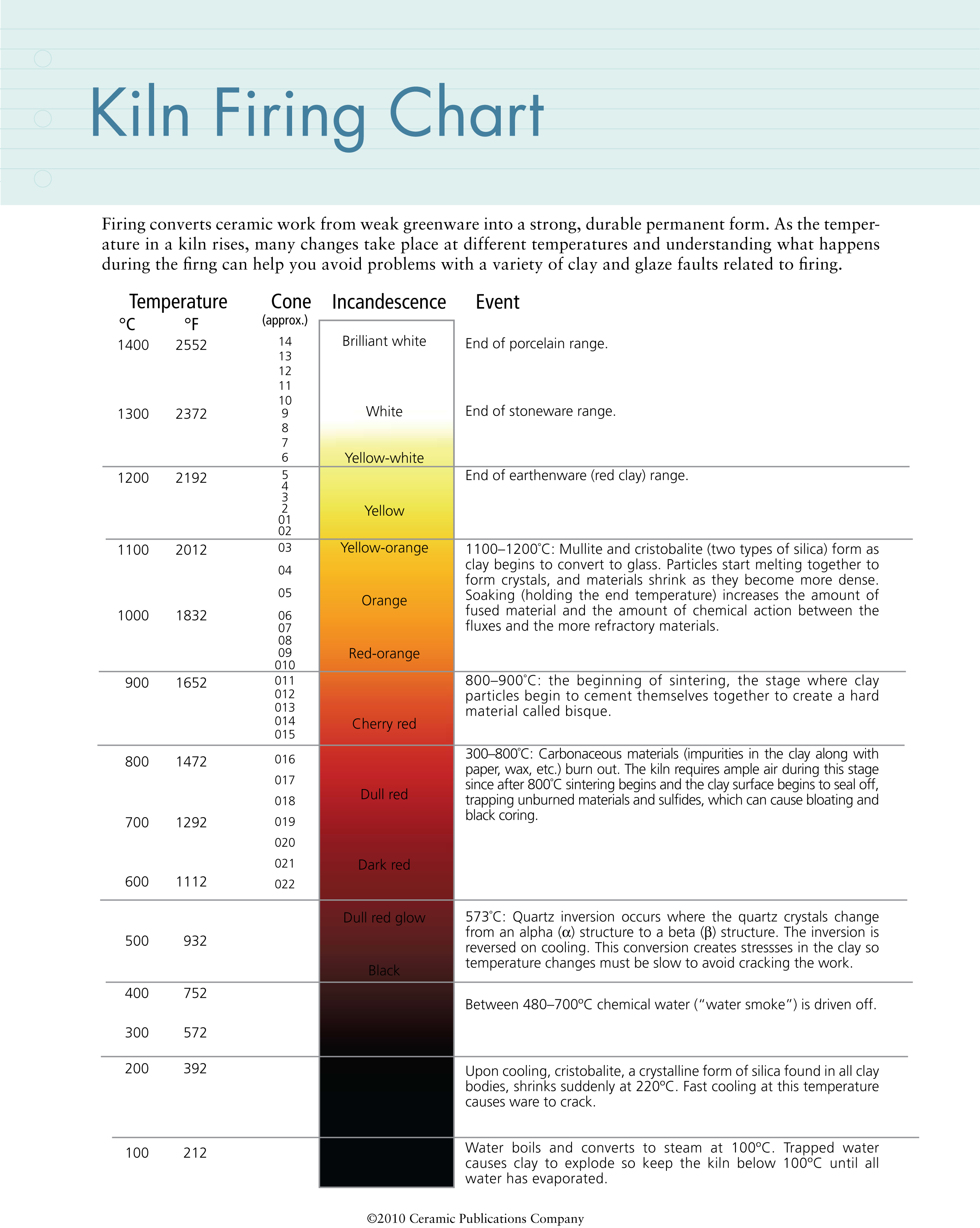

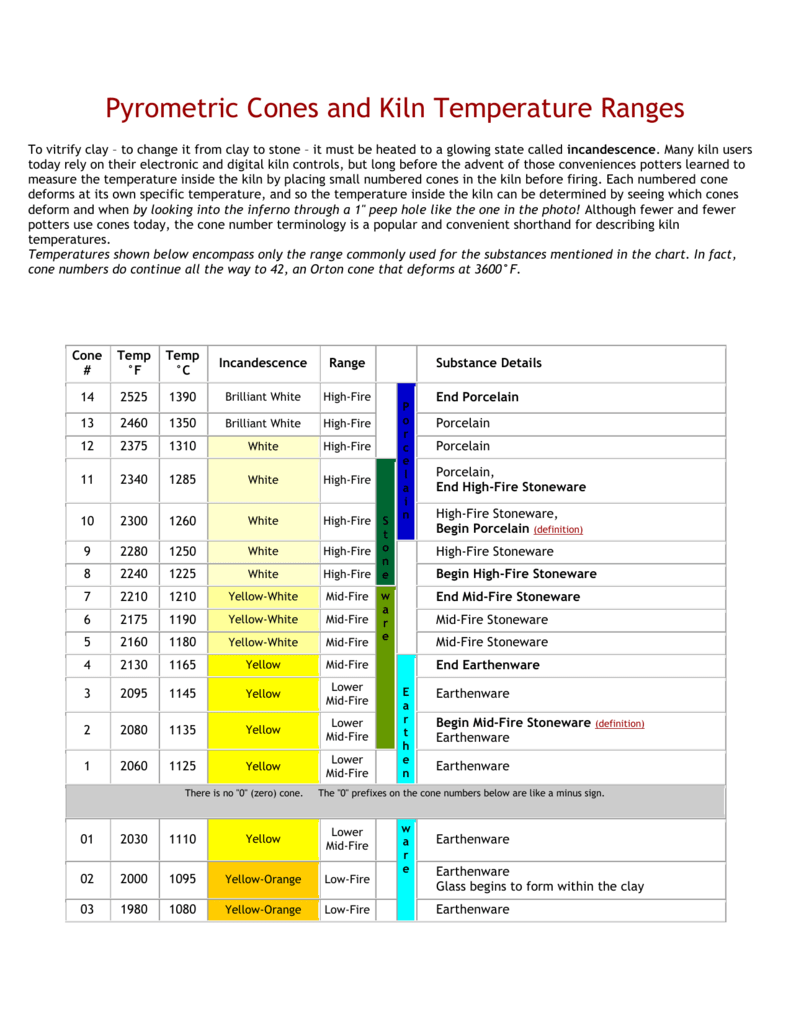

Web pyrometric kiln cones measure heat absorption as kiln temperatures reach heating ranges. Keep the chart near your kiln for quick reference. Learn how cones work & how to use them. This guide provides useful information on cones and how firings can affect your pottery. Web pyrometric cones have been used to monitor ceramic firings for more than 100 years.

They are useful in determining when a firing is complete, if the kiln provided enough heat, if. Web generate cone temperature chart and see the conversion between kiln cones in fahrenheit and celsius based on selected heat rate increase. Web download and print the orton cone wall chart at sheffield pottery. Web pyrometric cones have been used to monitor ceramic firings for more than 100 years. They measure “heat work” during a firing, or time plus temperature.

Keep the chart near your kiln for quick reference. They are useful in determining when a firing is complete, if the kiln provided enough heat, if. Web pyrometric cones are designed to melt at certain temperatures in a kiln. This deforming action allows us to either shut the kiln off at the proper point (as in the case of. Web pyrometric cones are designed to deform at certain moments during a firing.

Web all of our resources for orton's pyrometric cones. Keep the chart near your kiln for quick reference. They are useful in determining when a firing is complete, if the kiln provided enough heat, if. Learn how cones work & how to use them. This guide provides useful information on cones and how firings can affect your pottery. Web pyrometric cones are designed to deform at certain moments during a firing. They measure “heat work” during a firing, or time plus temperature. Web this pyrometric cone chart provides the temperature equivalents for orton cones based on specific heating rates. Web differences between a cone touching the shelf and a cone at the 4 o’clock position are small, usually 1 or 2 degrees. Web this comprehensive chart shows the temperatures of orton pyrometric cones in degrees f. Web download and print the orton cone wall chart at sheffield pottery. Web this is a chart showing the temperatures and firing rates at which various cones bend. Temperatures are shown for specific heating rates. Web temperatures shown on the charts were determined under controlled firing conditions in electric kilns and an air atmosphere. Web pyrometric cones have been used to monitor ceramic firings for more than 100 years.

Web This Pyrometric Cone Chart Provides The Temperature Equivalents For Orton Cones Based On Specific Heating Rates.

This deforming action allows us to either shut the kiln off at the proper point (as in the case of. They are useful in determining when a firing is complete, if the kiln provided enough heat, if. Web differences between a cone touching the shelf and a cone at the 4 o’clock position are small, usually 1 or 2 degrees. Refer to this cone temperature chart before firing.

Web Generate Cone Temperature Chart And See The Conversion Between Kiln Cones In Fahrenheit And Celsius Based On Selected Heat Rate Increase.

Learn how cones work & how to use them. Web pyrometric kiln cones measure heat absorption as kiln temperatures reach heating ranges. Web pyrometric cones have been used to monitor ceramic firings for more than 100 years. Web pyrometric cones have been used to monitor ceramic firings for more than 100 years.

Web All Of Our Resources For Orton's Pyrometric Cones.

Temperatures are shown for specific heating rates. Web there are 4 styles of pyrometric cone: Web pyrometric cones are designed to deform at certain moments during a firing. Have you ever glanced at those perplexing columns detailing different firing temperatures for the same cone number and wondered.

Web Download And Print The Orton Cone Wall Chart At Sheffield Pottery.

They are useful in determining when a firing is complete, if the kiln provided enough heat, if. Web pyrometric cones are designed to melt at certain temperatures in a kiln. Web this comprehensive chart shows the temperatures of orton pyrometric cones in degrees f. To produce a properly fired result, the next cone higher in sequence is placed into the shutoff device and the result is confirmed by a cone placed inside the kiln.

![Kiln Firing Chart for Pottery and Ceramics [Infographic]](https://www.kilncontrol.com/wp-content/uploads/2023/07/Kiln-Firing-Chart-for-Pottery-and-Ceramics-Infographic-1.png)