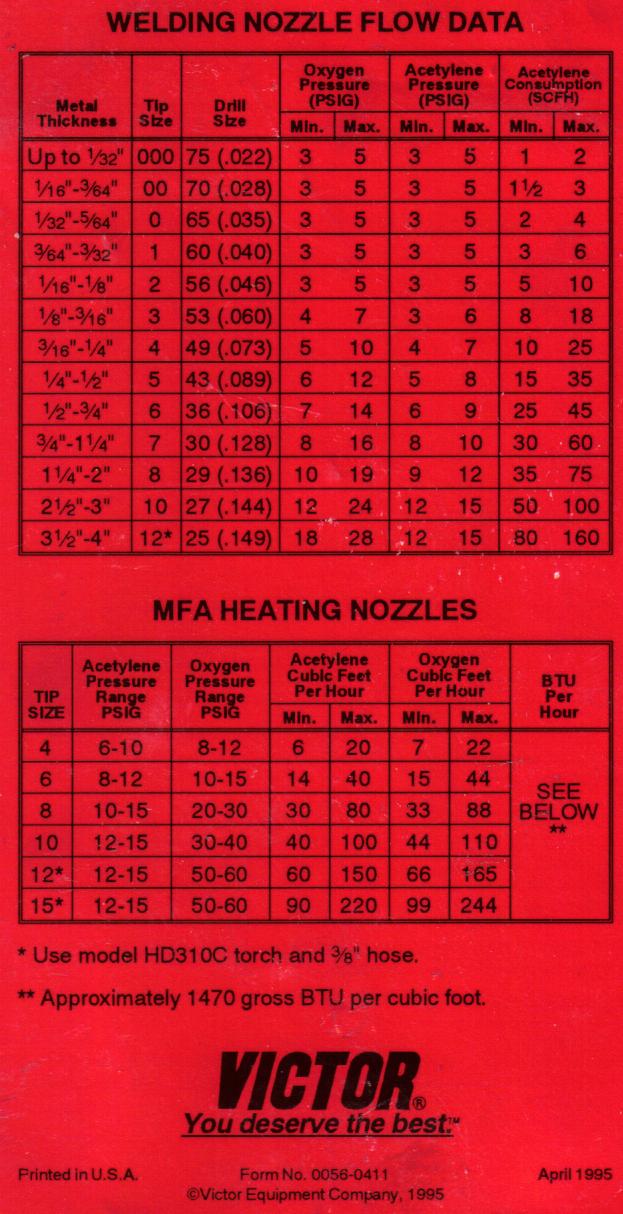

Tip orifice shown above at actual size. Arrows on the top of the valve indicate the correct direction for opening and closing if you are not sure. Tip size numbers vary among manufacturers, so orifice sizes are shown in number drill sizes. A larger tip will generate more heat, while a. Valley center, ks 67147 phone:

Open the acetylene cylinder no more than one turn. The recommended setting is for the fuel gas regulator to be set at 10 psig and the oxygen regulator at 45 psig. Web if the hole drill sizes correlate to pressure/cutting metal thickness and i think it does, then this chart shows drill sizes for welding tip size on one side and cutting on opposite side. Web acetylene welding tips sizes oxy acetylene cutting tip size victor welding torch tip size. Web the first step in setting up your oxy acetylene rosebud torch is to choose the right tip.

The cutting side only shows tip size. A larger tip will generate more heat, while a. The welding tip chart shows the proper tip sizes and oxygen and acetylene pressures related to the thickness of material to be welded. Hundreds of tips for more than 20 brands are listed in this catalog; For the first time, equipment including outfits, handles,.

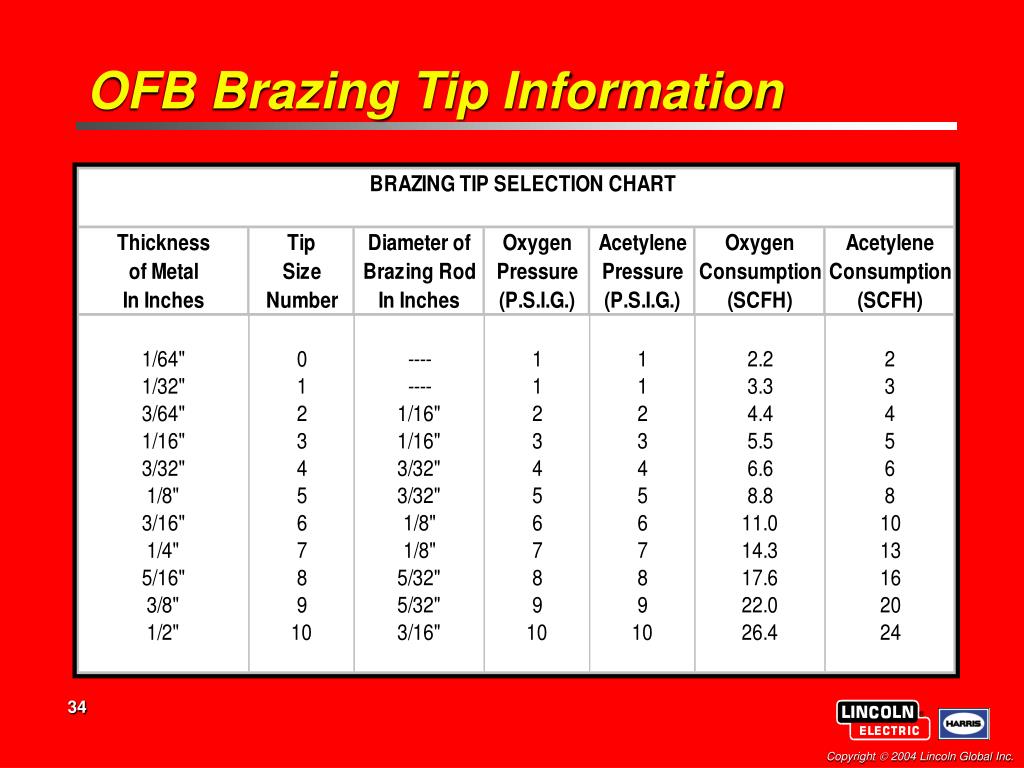

For the first time, equipment including outfits, handles,. If too large a tip is used and the flame softened, the tip heats up unnecessarily and is often accompanied by a popping noise. Valley center, ks 67147 phone: Hose for cutting 2 (51 mm) steel and above. Web acetylene tips are manufactured with four or six preheat holes and are produced to allow light, medium, and heavy preheats for use with clean, dirty, or rusted plate. Including harris®, esab®, smith®, and victor®. Tip sizes are often labeled differently depending on the manufacturer, as companies have no industry standards to follow. Hundreds of tips for more than 20 brands are listed in this catalog; Web orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. Web the first step in setting up your oxy acetylene rosebud torch is to choose the right tip. The thickness of the workpiece metal will determine the size of the tip, with thicker metals typically requiring bigger tips. Web data based on 25 ft (7.6 m) of 3/16 in. Refer to welding tip selection chart to determine the recommended tip size and regulator pressure setting for the job. The cutting side only shows tip size. Gas pressure) tip brazing brazing no.

Open The Acetylene Cylinder No More Than One Turn.

The welding tip chart shows the proper tip sizes and oxygen and acetylene pressures related to the thickness of material to be welded. Arrows on the top of the valve indicate the correct direction for opening and closing if you are not sure. Web orifice (drill size) pressure (psi) tables show approximate gas pressures for welding or cutting. Web match your torch type, your cutting fuel, and your material thickness to begin reviewing which tip size is appropriate for your cutting setup.

If Too Large A Tip Is Used And The Flame Softened, The Tip Heats Up Unnecessarily And Is Often Accompanied By A Popping Noise.

Alternate fuel tips are also available for gouging, rivet washing, and cutting close to bulkheads. In order to comfortably and safely see the flame when welding or cutting, welding goggles must be worn. The tip size is determined by the orifice for cutting oxygen gas. The thickness of the workpiece metal will determine the size of the tip, with thicker metals typically requiring bigger tips.

Tip Size Numbers Vary Among Manufacturers, So Orifice Sizes Are Shown In Number Drill Sizes.

Mm flames fuel gases & oxy. Valley center, ks 67147 phone: The cutting side only shows tip size. Recommended oxygen acetylene torch best practices:

Web Recommended Oxy/Acetylene Cutting Tip Pressures Vary With Size.

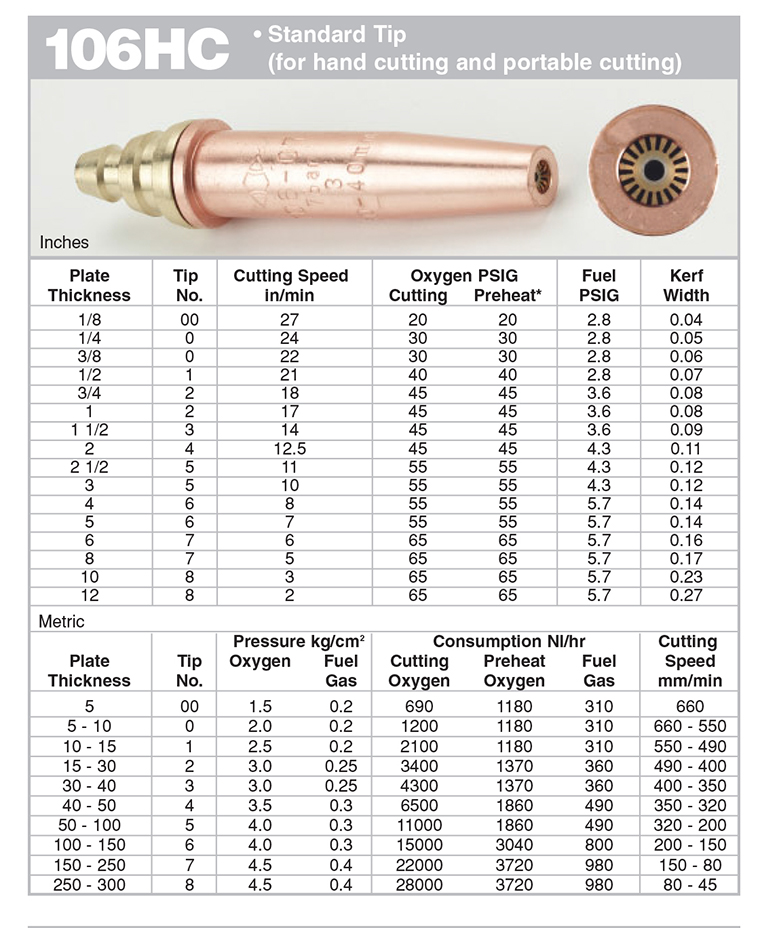

Use the right tip size for every job. Each gas fuel needs the proper torch tip in order to be used properly and efficiently. Acetylene adaptor at40 lp adaptor at41 (injector) (works to 4 oz. Web the tip sizes range from 000 to 8, coinciding with a metal thickness of 1/8 to 12 inches.