Web setting the correct working pressures. Pure oxygen is used for the cutting jet and it's mixed with either acetylene, propane, or. Check the thickness of the metal to be cut or welded. First, we must clean the nozzle because if the head of the nozzle is dirty will cause a flame bad. Web oxygen acetylene torch 101:

First, we must clean the nozzle because if the head of the nozzle is dirty will cause a flame bad. Web there's lots of info in that chart but i still have two questions: Pure oxygen is used for the cutting jet and it's mixed with either acetylene, propane, or. Selecting the correct cutting tips. Web setting the correct working pressures.

Once everything is set up correctly, and you have adjusted the flame size appropriately for your job at hand, now it’s time for some action! 1) the table lists victor, harris, and airco seat types. Everyone in the hvac/r trade uses some type of torch to braze or solder alloys together. Pure oxygen is used for the cutting jet and it's mixed with either acetylene, propane, or. Web there's lots of info in that chart but i still have two questions:

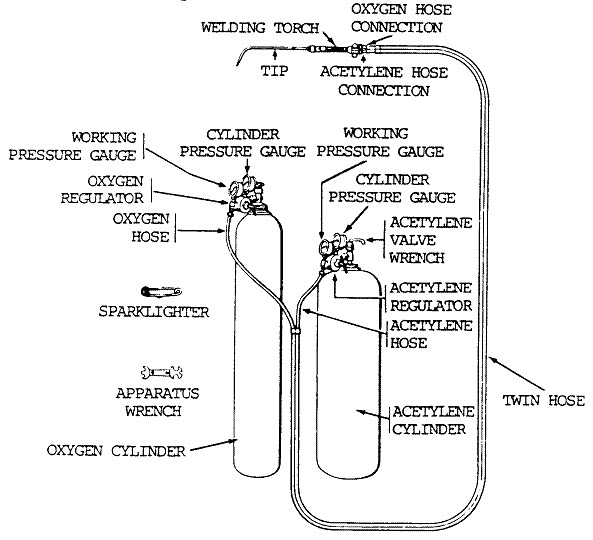

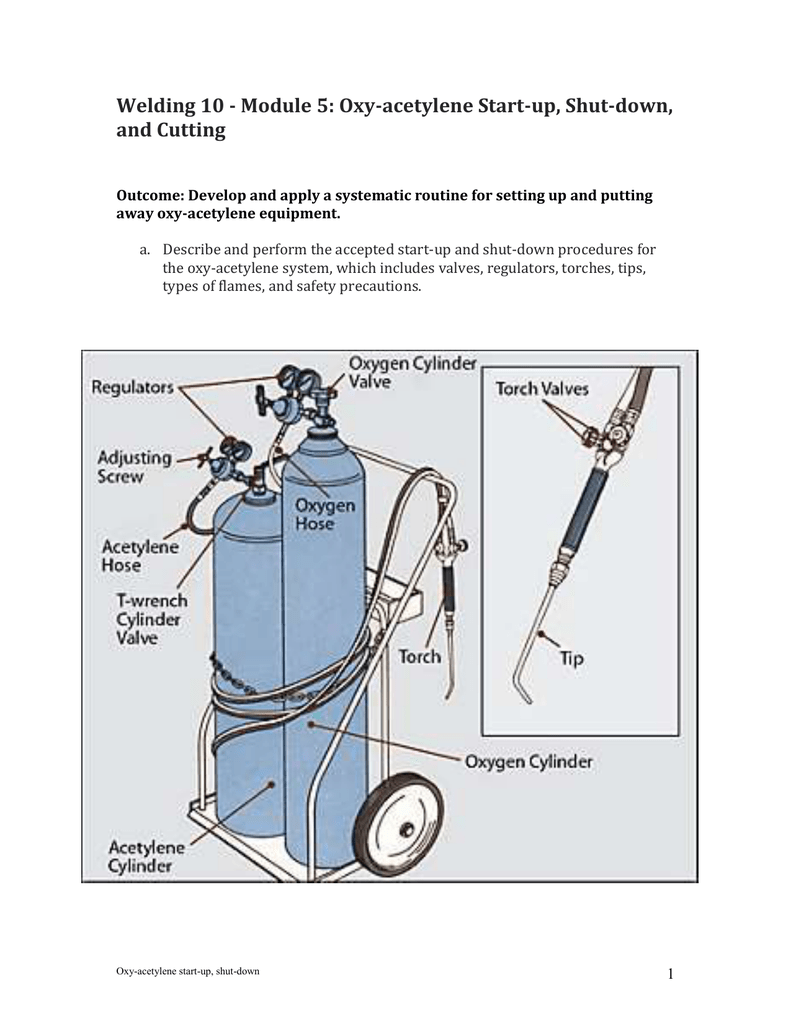

Everyone in the hvac/r trade uses some type of torch to braze or solder alloys together. By understanding the basics, selecting the right tip, setting proper gas. So, what is the proper way to handle an. Web setting the correct working pressures. Do you happen to know which type seat is most. Web carrying out your job. Refer to welding tip selection chart to determine the recommended. First, we must clean the nozzle because if the head of the nozzle is dirty will cause a flame bad. How to select the correct cutting tips for your oxygen acetylene torch. 1) the table lists victor, harris, and airco seat types. Web mastering the oxy acetylene cutting torch settings is essential for achieving clean and efficient cuts. Discover welding techniques, tips, and more. Welding requires a steady hand and precise movements. Web oxy acetylene welding set up and pressure settings chart : Make use of correct welding & cutting technique.

Web Setting The Correct Working Pressures.

Everyone in the hvac/r trade uses some type of torch to braze or solder alloys together. Check the thickness of the metal to be cut or welded. Pure oxygen is used for the cutting jet and it's mixed with either acetylene, propane, or. Discover welding techniques, tips, and more.

Web There's Lots Of Info In That Chart But I Still Have Two Questions:

Web oxygen acetylene torch 101: Web keep a steady hand. So, what is the proper way to handle an. This guideline will let you.

1) The Table Lists Victor, Harris, And Airco Seat Types.

Welding requires a steady hand and precise movements. Web do a quick visual inspection of the hoses and equipment. Web the ideal cutting settings for oxy acetylene depend on factors like material type, thickness, and torch tip size. Web mastering the oxy acetylene cutting torch settings is essential for achieving clean and efficient cuts.

Selecting The Correct Cutting Tips.

Refer to welding tip selection chart to determine the recommended. By understanding the basics, selecting the right tip, setting proper gas. Once everything is set up correctly, and you have adjusted the flame size appropriately for your job at hand, now it’s time for some action! Whether you are buying your.