Different welding rods sizes, types, and their uses. The most common diameter for general purpose welding is 3/32, 1/8 inch, and 5/32 inch. How to choose a correct welding rod size. Avoiding contamination and moisture absorption. It is made out of materials with a similar composition to the metal being welded.

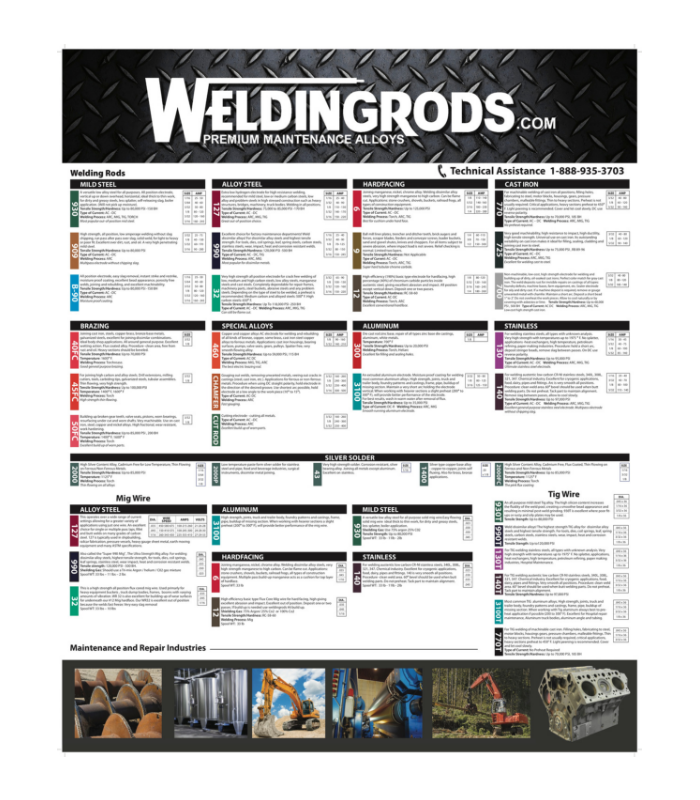

So, choosing the appropriate welding rod size is crucial. Web if you are looking for welding rod charts, we created the ultimate resource, listing everything from electrode sizes and amps to how much welding rod you need This size is used for carbon steel. We cover everything related to rod types, sizes, and how to pick the right one for your needs. Different welding rods sizes, types, and their uses.

The stick welding process is also called shielded metal arc welding (smaw). Web home » welders » stick welders. Web this chart should serve as a guide for all your welding rod size needs and will provide education and knowledge about the selection process as well. How to choose a correct welding rod size. Consider the base metal (s) you will be welding.

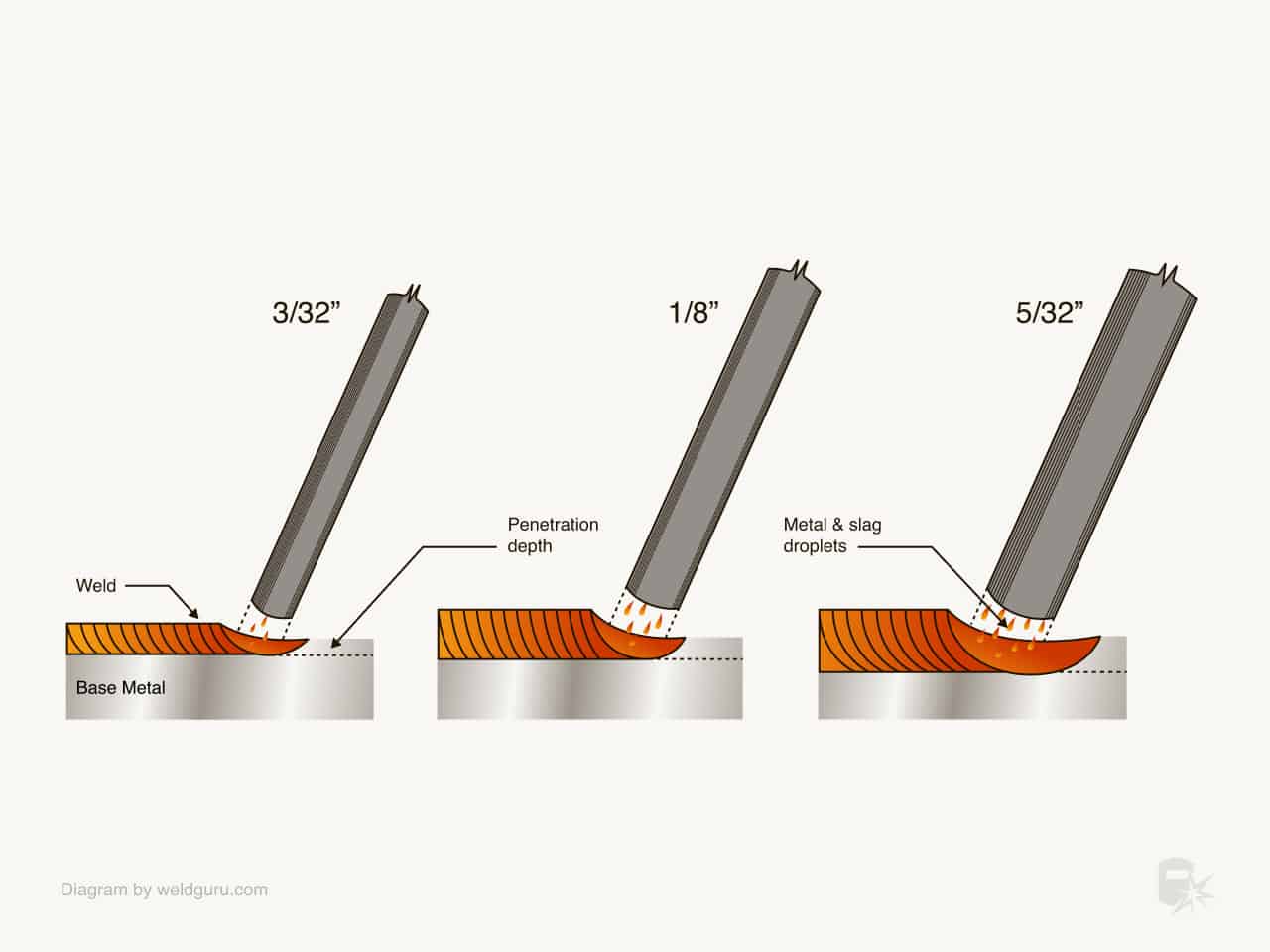

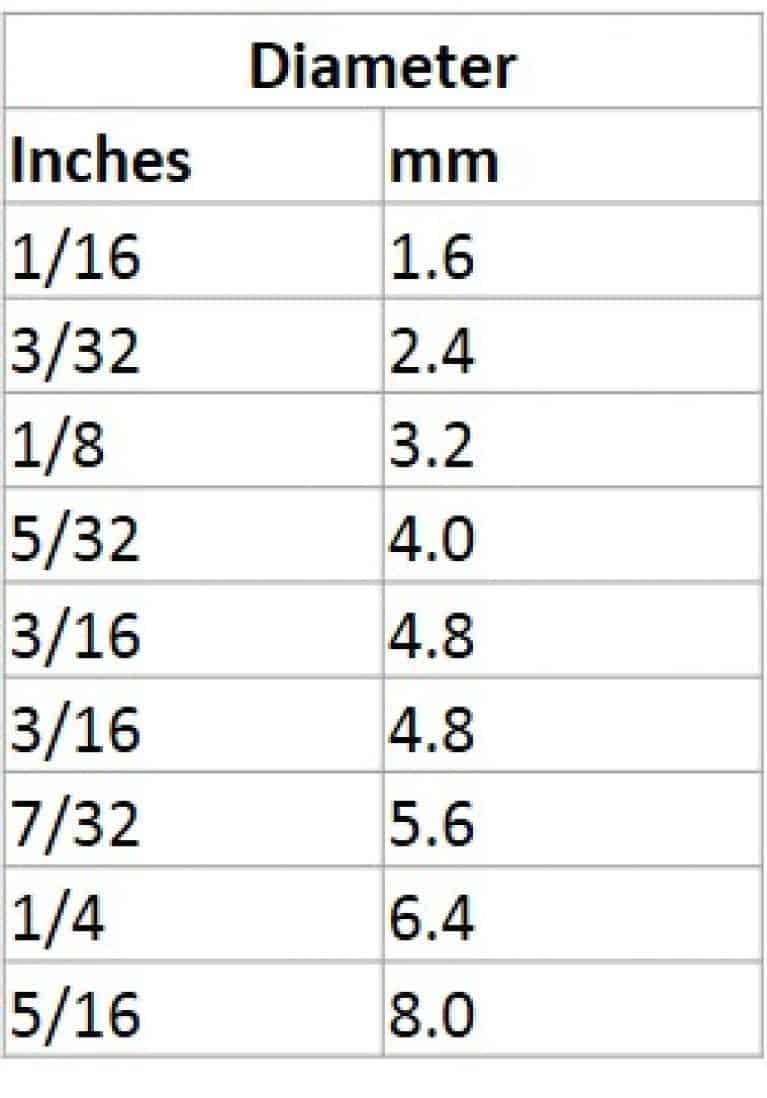

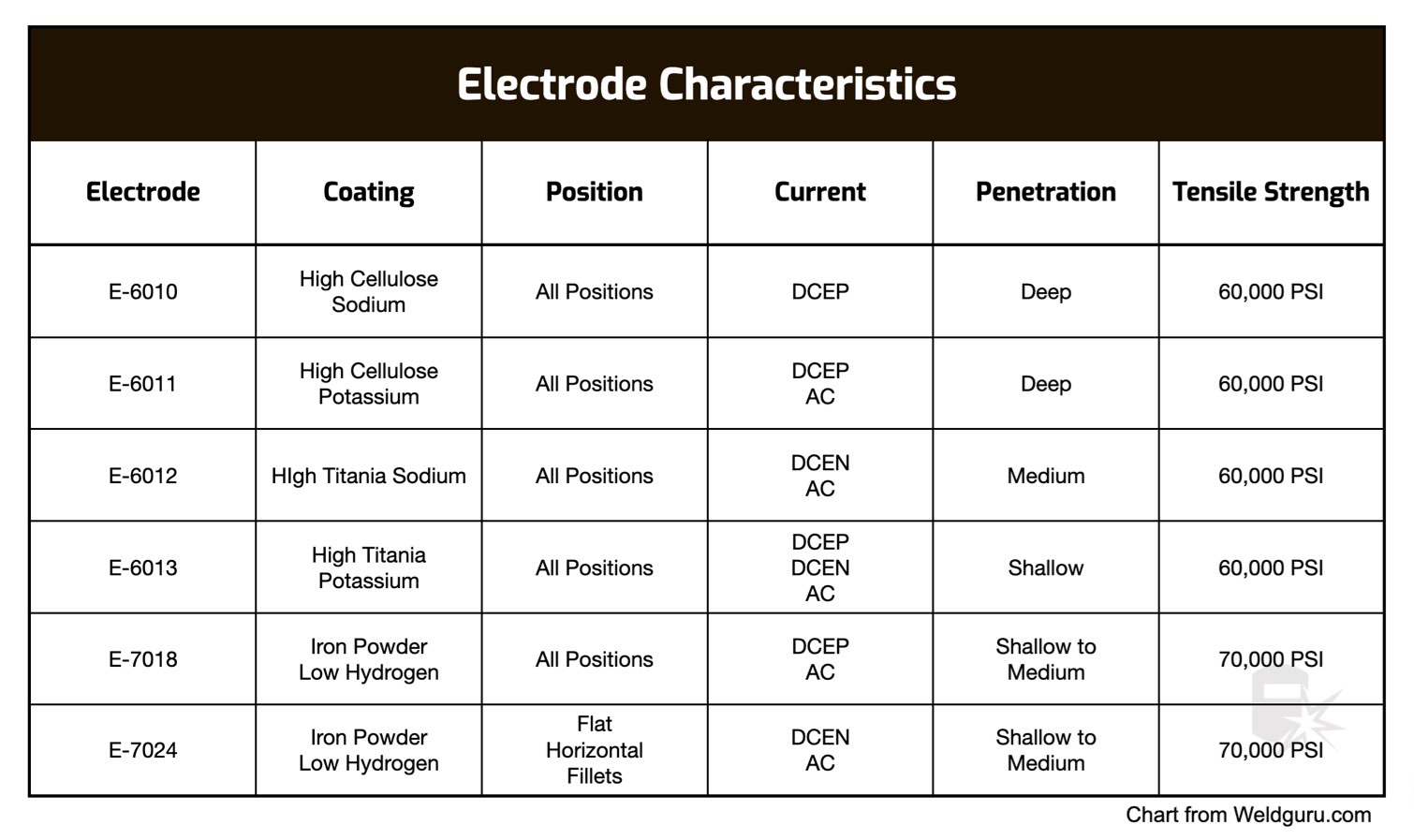

Web welding electrodes & filler rods explained. There are a variety of factors that go into choosing the right electrode for each project. Web our powerful calculator let's you easily determine which stick electrode you need. The table is published in aws a5.1 specification. These guidelines can vary between different manufacturers so always check the manufacturer’s guidelines if possible. Web this chart should serve as a guide for all your welding rod size needs and will provide education and knowledge about the selection process as well. Web the most popular welding rod sizes for home welders are 3/32″, 1/8″, and 5/32″, as they are suitable for common projects. Below is a chart that will give you a starting point for choosing the correct welding rod size. Take a look at the image below to see a typical stick welding setup. Web see our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables. You should not be perplexed with these numbers for these numbers correspond to certain values. The american welding society (aws) has created a numbering classification 5.1 that is the most commonly used way of differentiating between stick electrodes. What are the common sizes of tig welding rods? Balancing quality and economic factors. We cover everything related to rod types, sizes, and how to pick the right one for your needs.

Web To Choose The Right Welding Rod, You Need To:

Web aws classification numbers explained. We cover everything related to rod types, sizes, and how to pick the right one for your needs. This chart provides valuable information on which rod size to use for different metal thicknesses and welding positions. Consider the base metal (s) you will be welding.

Different Welding Rods Sizes, Types, And Their Uses.

What is the best welding rod for a beginner?. How do you know what size welding rods to use? 2.1 how is welding rod diameter measured? Web see the chart below that details some of the weld characteristics for each coating.

Web Our Powerful Calculator Let's You Easily Determine Which Stick Electrode You Need.

Web see our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables. Plus a chart with rod size and amperage per metal thickness in inches and mm. Web welding rod sizes with amperage chart. Proper rod storage to retain performance.

This Size Is Used For Carbon Steel.

How to choose a correct welding rod size. How to build welding lead reels. The table is published in aws a5.1 specification. Know about current and polarity.