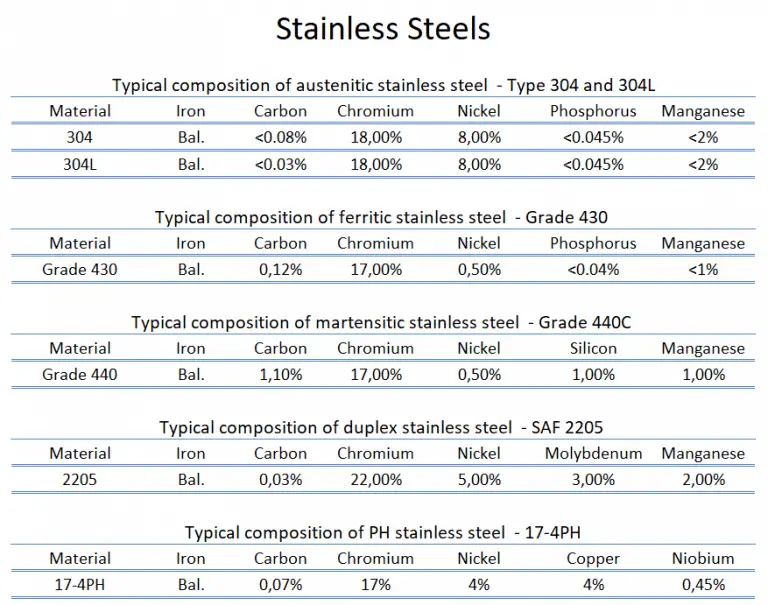

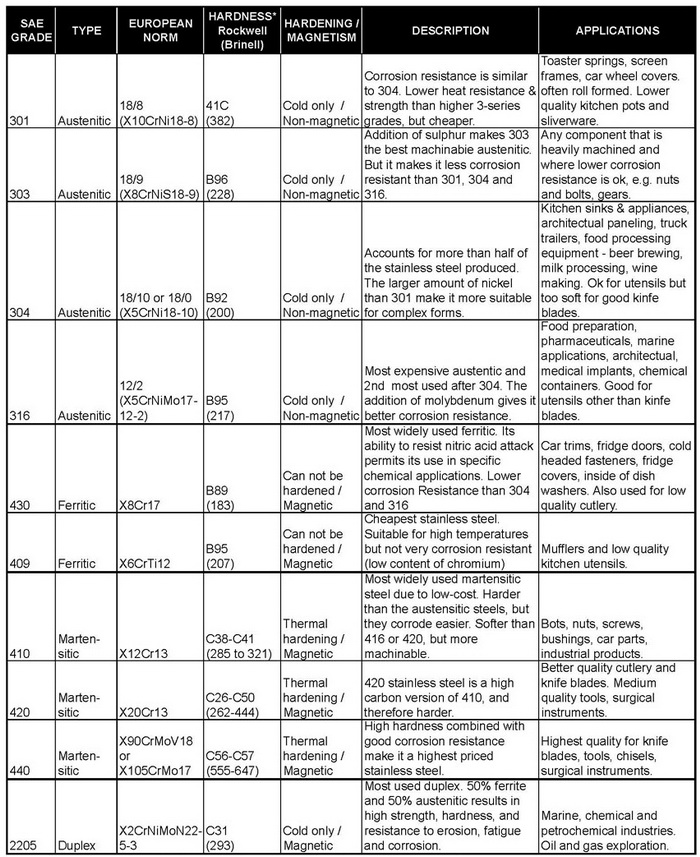

There are different grades of stainless steel, which are distinguished by their chemical and mechanical properties. General purpose ferritic grade awm404gp® stainless steel. In this article we cover: Less carbon content to increase corrosion resistance. When you pair a family and grade together, you get a good indication of what to expect from a specific stainless steel alloy.

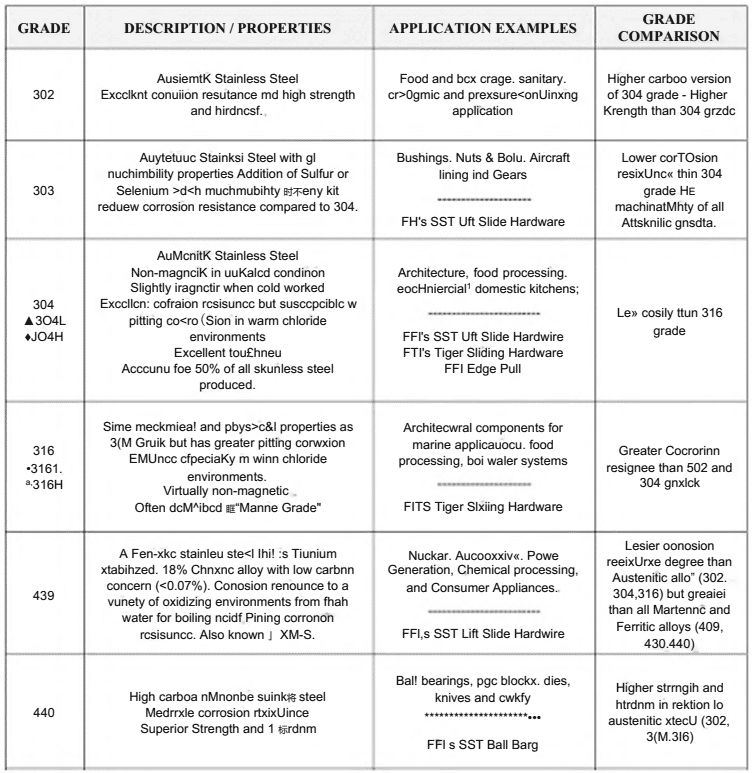

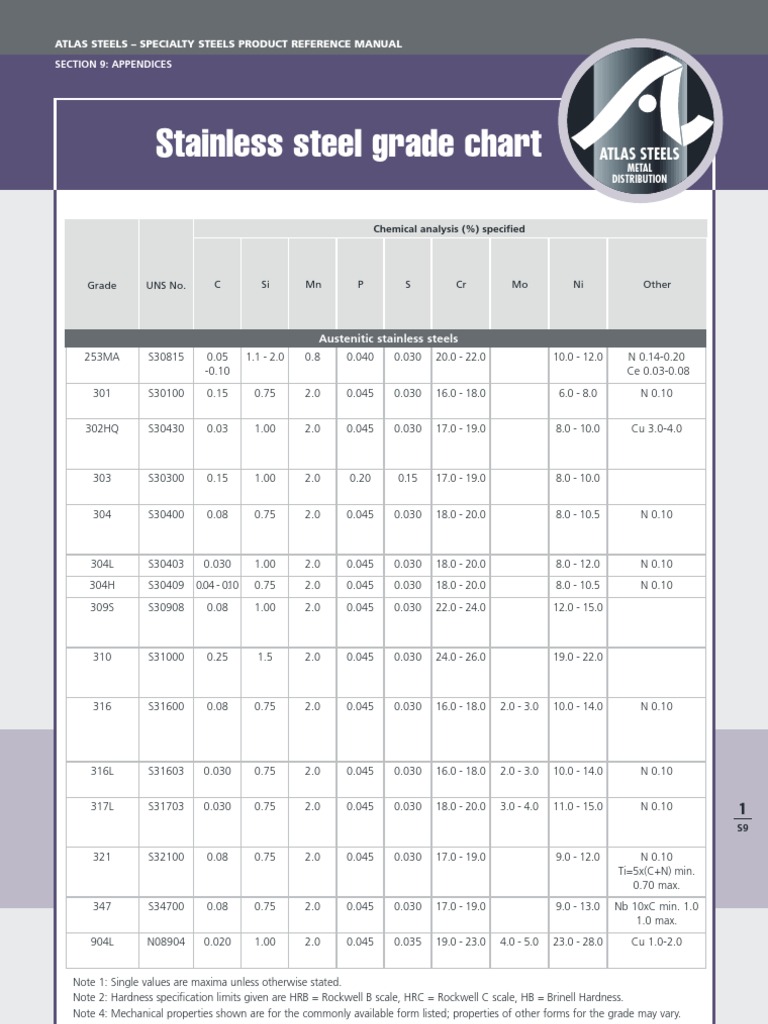

To help you navigate the world of stainless steel grades, we've compiled a detailed chart that highlights the composition, characteristics, and common applications of the most widely used grades. Less carbon content to increase corrosion resistance. First, let’s look at what stainless steels are. Web a useful chart of relevant information on austenitic, ferritic, duplex, martensitic, and precipitation hardening grades of stainless steels including: Must be hardened for maximum heat and corrosion resistance.

** ‘h’ denotes high carbon content: Comparative designations of grades with similar composition from other important standards. General purpose ferritic grade awm404gp® stainless steel. In this article we cover: Web these are plain chromium (10.5 to 18%) grades such as grade 430 and 409.

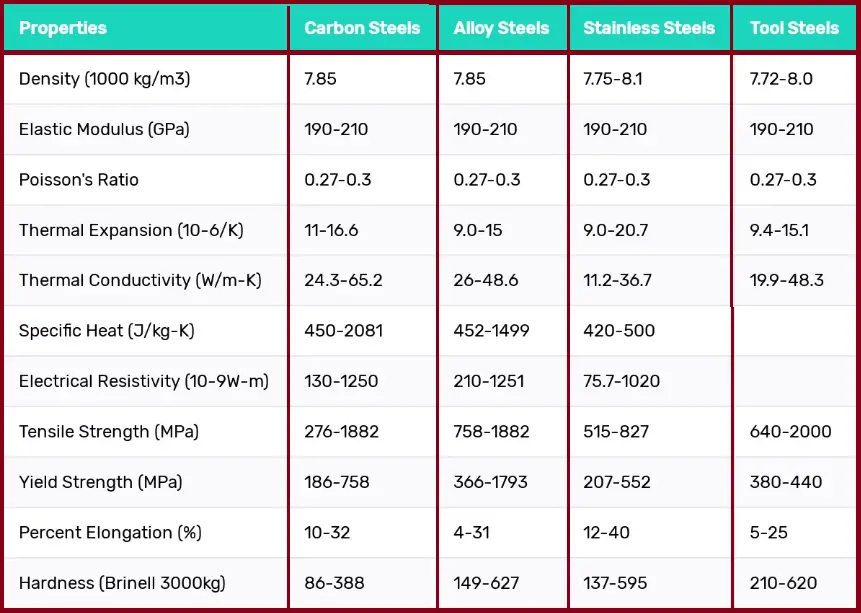

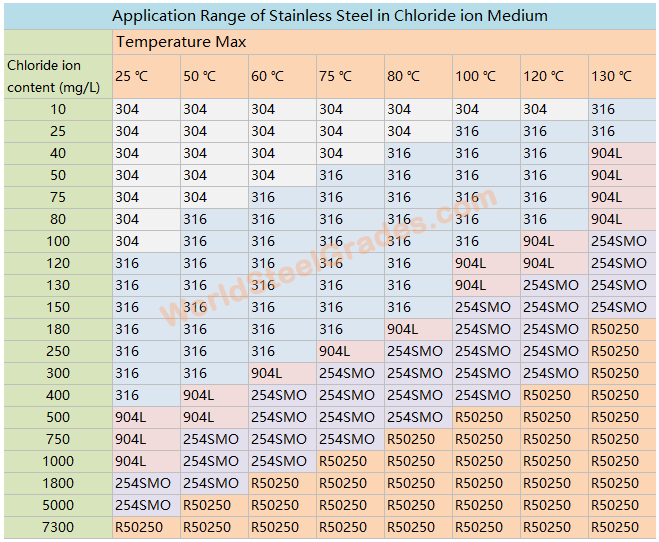

Web there are numerous grades of stainless steel within each category—here are the breakdowns of the most common varieties of each: Web most common grades of stainless steel. You can learn about everything from magnetism and toughness to corrosion resistance and heat resistance. Web stainless steel grades chart and comparison (includes din, astm, jis etc. Grade 301 stainless steel is comprised of additions of chromium and nickel and has exceptionally corrosion resistance. There are a lot of different grades of stainless steel. The relationship between the various ferritic grades is shown in figure 3. Stainless steel grade composition chart. Must be hardened for maximum heat and corrosion resistance. General purpose ferritic grade awm404gp® stainless steel. Web stainless steel grades: What are grades of stainless steel? ** ‘h’ denotes high carbon content: Web the most common us grades of stainless steel are: The duplex structure uses the same amount of ferrite and austenite.

Web The Four Main Kinds Of Stainless Steel Are:

Stainless steel grade composition chart. Web stainless steel grades chart. Must be hardened for maximum heat and corrosion resistance. Web most common grades of stainless steel.

Typical Applications Include Cold Heading, Bolts, Nuts And Screws, Pump Parts And Shafts, Steam And.

Web this results in hundreds of different grades of stainless steel that are covered by a range of national and international standards. Grade 301 stainless steel is comprised of additions of chromium and nickel and has exceptionally corrosion resistance. To help you navigate the world of stainless steel grades, we've compiled a detailed chart that highlights the composition, characteristics, and common applications of the most widely used grades. There are a lot of different grades of stainless steel.

Web These Are Plain Chromium (10.5 To 18%) Grades Such As Grade 430 And 409.

Common types of austenitic stainless steels. The duplex structure uses the same amount of ferrite and austenite. There are different grades of stainless steel, which are distinguished by their chemical and mechanical properties. The amount of chromium ranges from 18 to 28%, and the amount of nickel ranges from 4.5 to 8%.

Web There Are Numerous Grades Of Stainless Steel Within Each Category—Here Are The Breakdowns Of The Most Common Varieties Of Each:

Web a guide to 300 and 400 series stainless steel grades, including material properties, key benefits, applications, and more. Comparative designations of grades with similar composition from other important standards. Web check out the stainless steel grades for austenitic, ferritic, and duplex stainless steel. In this article we cover: