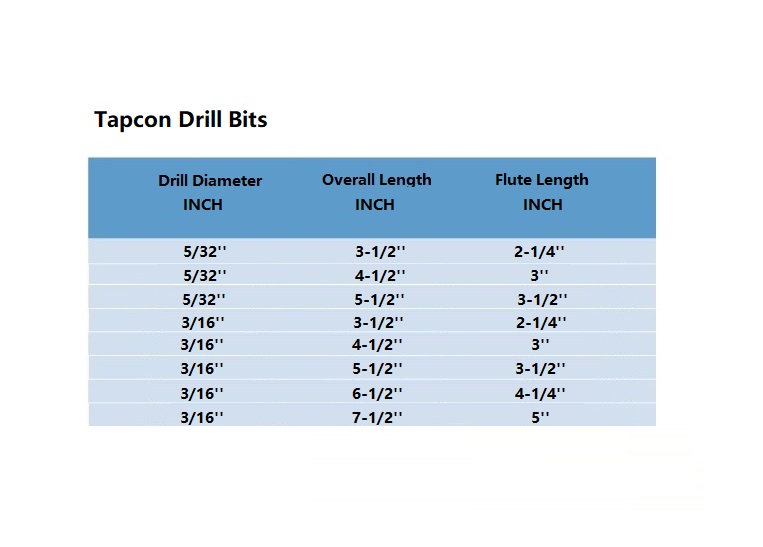

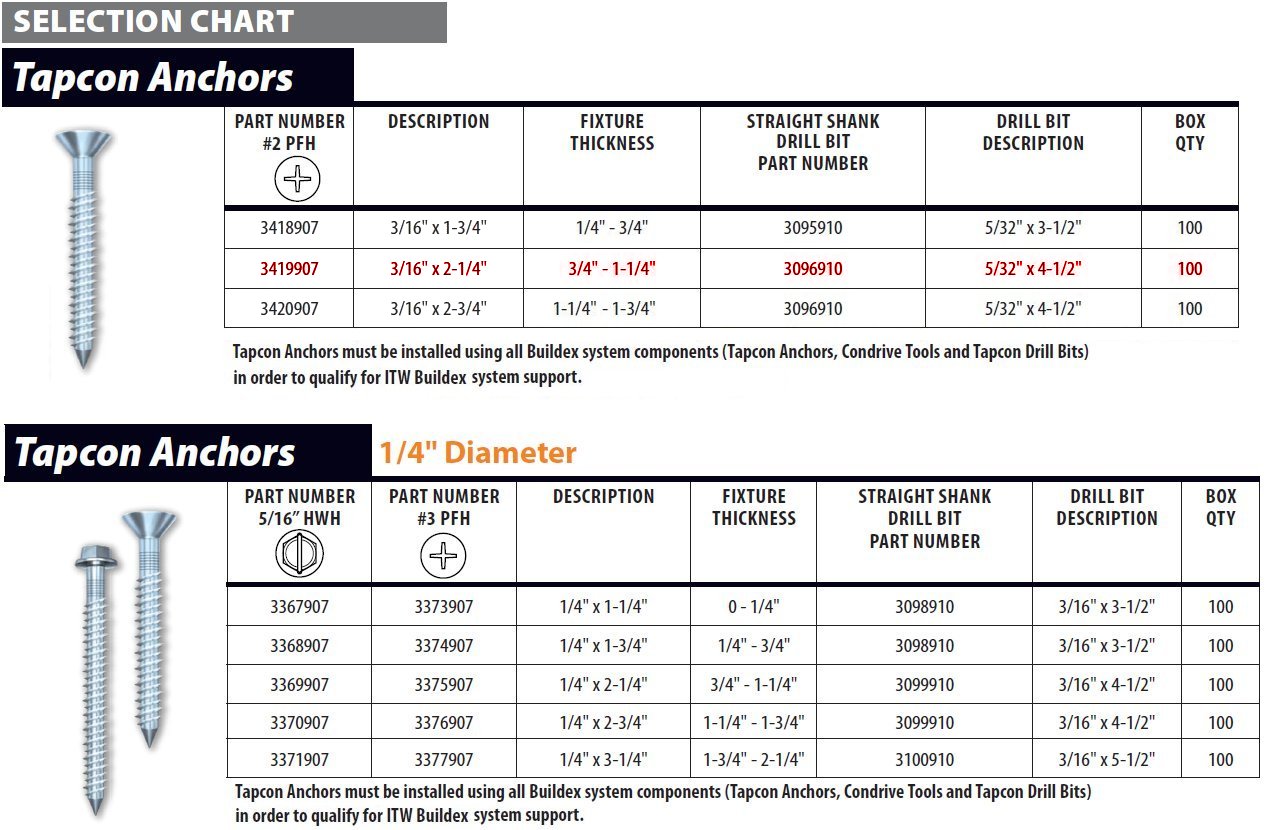

Secure the drill bit in the power drill and make sure it’s aligned and tight. Web the following charts show the diameter and length of the tapcon screw and the diameter and overall length of the carbide bit for the straight shank, sds, sds max, and spline bit. Tapcon is packaged 100 pieces per box and 500 pieces per master carton except 3205407 and 3203407 (400 in master carton). Using a socket wrench insert anchor into hole Web our concrete screw anchors deliver 30% less torque and 20% more holding power, while our drill bits make it possible to create precise holes at maximum power.

Variations in the drill bit size can affect the efficiency of the screw’s installation and the strength of its hold. Web our concrete screw anchors deliver 30% less torque and 20% more holding power, while our drill bits make it possible to create precise holes at maximum power. Secure the drill bit in the power drill and make sure it’s aligned and tight. Patented sawtooth ™ thread design drives easily into concrete to optimize pullout performance and There are numerous technical specifications that must be considered when using tapcon® screws.

Web when it comes to 3/8 tapcons, consider the drill bit size. The diameter of the bit required and the length of the bit. This is key for a secure fit. After setup, each tapcon screw must meet the required embedment depth. Web tapcon concrete screw technical specifications and information.

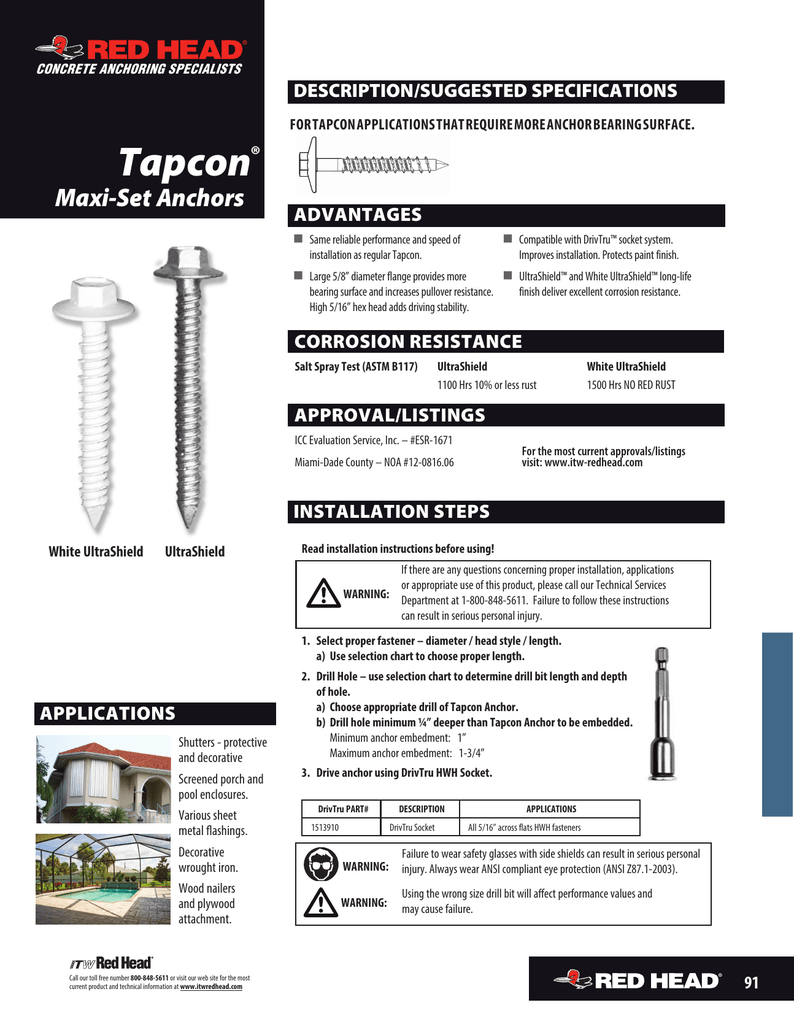

Check the packaging or manufacturer’s instructions for more details. A sds shank tapcon drill bit can be expected to drill 100 holes minimum to full depth in 4,000 psi concrete. A straight shank tapcon drill bit can be expected to drill 60 holes minimum to a 2 depth in 4,000 psi concrete. Web most tapcon screw sizes need a 5/32 inch drill bit. Approved for use in acq treated lumber. Tapcon is packaged 100 pieces per box and 500 pieces per master carton except 3205407 and 3203407 (400 in master carton). Web tapcon concrete screw technical specifications and information. By the end, you’ll be able to find the right drills and drill bits to get the strongest holding threads that offer an accurate fit, thus obtaining higher tolerances for your concrete anchors. Secure the drill bit in the power drill and make sure it’s aligned and tight. Web view detailed information about drill bits for tapcon cement screw anchors, sizes, length and where to purchase. There are numerous technical specifications that must be considered when using tapcon® screws. (see chart for socket size) (do not over tighten). Designed for use with a hammer drill and tapcon drill bits. There are multiple drill bit alternatives to use for different materials or to serve a different purpose. Tension strength design information for tapcon+ screw anchors1.

There Are Multiple Drill Bit Alternatives To Use For Different Materials Or To Serve A Different Purpose.

Tapcon is packaged 100 pieces per box and 500 pieces per master carton except 3205407 and 3203407 (400 in master carton). By the end, you’ll be able to find the right drills and drill bits to get the strongest holding threads that offer an accurate fit, thus obtaining higher tolerances for your concrete anchors. Tapcon® is a registered trademark of buildex, a divison of illinois tool works, inc. Tool drives 3/16” and 1/4” diameter tapcons.

Web Tapcon Sds Plus Drill Bits Are Specially Designed To Be Compatible With Condrive Pro Installation Kit.

Patented sawtooth ™ thread design drives easily into concrete to optimize pullout performance and Web most tapcon screw sizes need a 5/32 inch drill bit. Variations in the drill bit size can affect the efficiency of the screw’s installation and the strength of its hold. N single piece design—no nut and washer assembly.

Installs Both Head Styles And All Lengths Of Tapcons.

There are numerous technical specifications that must be considered when using tapcon® screws. A sds shank tapcon drill bit can be expected to drill 100 holes minimum to full depth in 4,000 psi concrete. Select a length that meets your application needs. Web using the proper size carbide bit (see chart) drill “a pilot hole at least 1” deeper than anchor embedment.

These Two Dimensions Should Match The Tapcon Size In Order To Achieve The Required Holding Values.

Web the following charts show the diameter and length of the tapcon screw and the diameter and overall length of the carbide bit for the straight shank, sds, sds max, and spline bit. Check the packaging or manufacturer’s instructions for more details. Web our concrete screw anchors deliver 30% less torque and 20% more holding power, while our drill bits make it possible to create precise holes at maximum power. Web the ideal drill bit size for a 5/16″ tapcon is generally a 1/4″ bit.