Thicker materials will require more current and thus bigger tungsten. Web in this article, we will explore the world of tig tungsten electrodes, their types, and usage, with the help of a color chart for easy reference. Web mainly on the material thickness and the amperage needed to achieve a proper weld. Web tungsten electrodes are used when arc welding with the tungsten inert gas (tig) process or when plasma welding. This type is often preferred for automated welding.

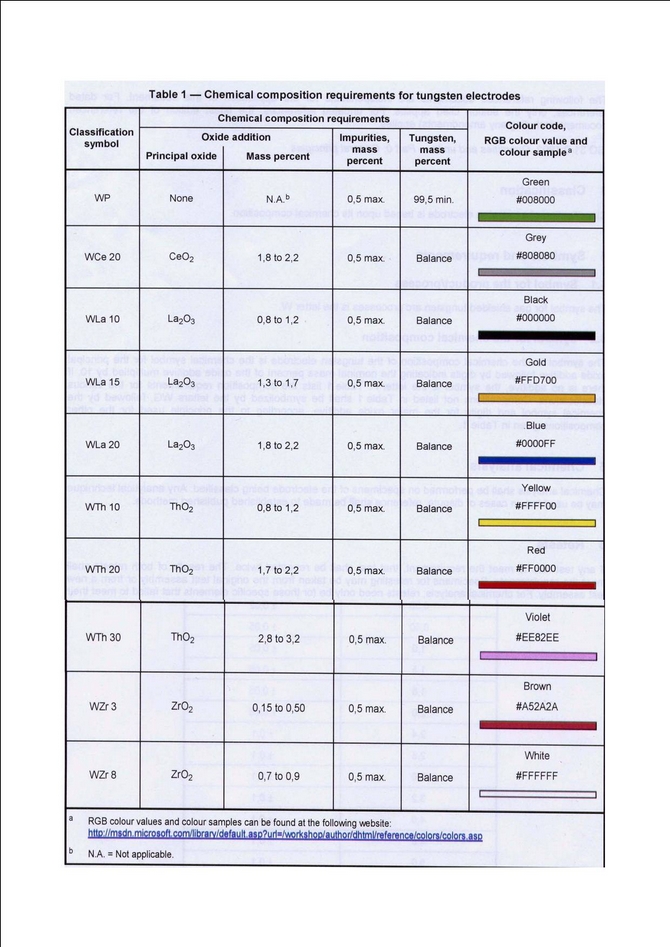

Web tungsten and oxide dispersed tungsten electrodes for arc welding and cutting. Tig tungsten size selection criteria. The american welding society document provides a table that shows the general current ranges for tungsten using direct current (dc) and alternating current (ac). Web the color chart below summarizes the various tig tungsten electrodes you may come across: Web a tig welding chart visually represents the welding parameters needed to achieve a specific weld.

The chart usually includes the current range, polarity, filler metal type, shielding gas type, and tungsten electrode size. Thicker materials will require more current and thus bigger tungsten. Web tungsten electrodes are essential for tig welding and come in several different types, each with its own unique characteristics and benefits. Web this article will discuss the different selection criteria for tig tungsten electrodes. Web tungsten electrodes are used when arc welding with the tungsten inert gas (tig) process or when plasma welding.

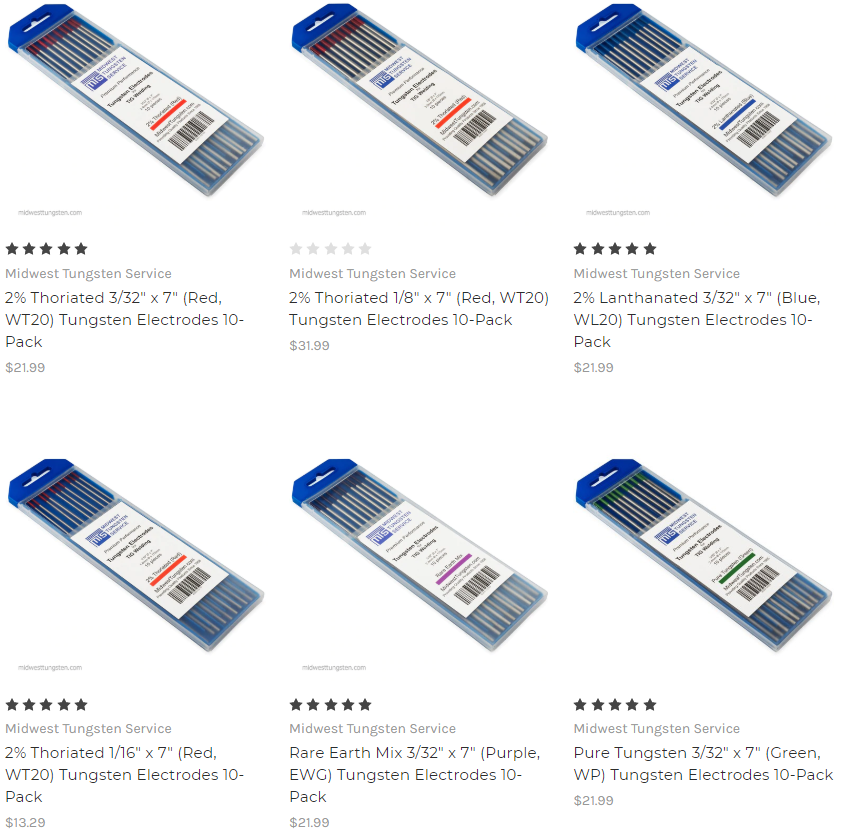

Web tungsten and oxide dispersed tungsten electrodes for arc welding and cutting. In both processes the electrode, arc and weld pool are protected from atmospheric contamination by an inert gas. Web tungsten electrodes are used when arc welding with the tungsten inert gas (tig) process or when plasma welding. Zirconiated tungsten (white) is good for welding aluminum and magnesium alloys. Gtaw was the official name at one time but it is now commonly referred to as tig. The american welding society document provides a table that shows the general current ranges for tungsten using direct current (dc) and alternating current (ac). Selecting the right tungsten electrode is an essential part of tig welding. We break down the different tungsten colors and explain when you should use each one. Here is a great reference guide to help you determine which electrode is right for your next job. This type is often preferred for automated welding. The chart usually includes the current range, polarity, filler metal type, shielding gas type, and tungsten electrode size. Web when it comes to tig welding, the most commonly asked question is “what tungsten do i use?” this tungsten selection guide will help you select the correct tungsten for your tig application. Our chart & guide explain types (pure, ceriated, etc.), colors, & best uses for flawless tig welds on steel, aluminum, & more! Browse suggested weld parameter settings for tig welding. Web tig, gtaw and argon welding are suitable tungsten processes.

This Type Is Often Preferred For Automated Welding.

Web what metal are you welding? Tig tungsten size selection criteria. Tig stands for tungsten inert gas and gtaw stands for gas tungsten arc welding. Web the color chart below summarizes the various tig tungsten electrodes you may come across:

Pure Tungsten Is Best Suited For Dc Welding Applications, While Lanthanide, Zirconiated, And Rare Earth Tungsten Electrodes Are Suitable For Both Ac And Dc Welding.

For beginners it’s recommended to stick with a 3/32” diameter tungsten. See the chart below for current ranges of all sizes. Selecting the right tungsten electrode is an essential part of tig welding. Web information on specifications and usage.

Web Tungsten And Oxide Dispersed Tungsten Electrodes For Arc Welding And Cutting.

Zirconiated tungsten (white) is good for welding aluminum and magnesium alloys. Here is a great reference guide to help you determine which electrode is right for your next job. The chart usually includes the current range, polarity, filler metal type, shielding gas type, and tungsten electrode size. Web this article will discuss the different selection criteria for tig tungsten electrodes.

Web Tungsten Electrodes Come In Various Compositions, Each With Distinct Properties That Make Them Suitable For Different Applications.

Web tig, gtaw and argon welding are suitable tungsten processes. Web this information applies only to the selection and preparation of electrodes for gas tungsten arc welding (gtaw), also known as tungsten inert gas (tig) welding and plasma arc welding (paw). There are many factors that affect the choice of the right tungsten size when tig welding—the weld amperages, material thickness, and tungsten type, to name a few. Click the chart to get the full size.