Web how much should i inflate my tractor tires? Proper ballast and tire pressure will maximize traction and tire life while minimizing fuel consumption and compaction. Web pressures at the bottom of the tire can be 1.5 psi higher than at the top. Calculate the weight needed for proper tractor setup. Web the air pressures in farm tractor tires are extremely important for getting the optimal wear and performance from the tires, as well as possibly avoiding dreaded downtime.

Web correct tire pressure for the load and speed will be manufacturer specific with each publishing charts with their recommendations. By properly inflating radial tires, you will reduce fuel consumption, finish your field work in less time, and reduce soil compaction. Understanding the gibberish printed on the sidewall of your tires is your first step to understanding what you need to buy to properly shod your mechanical workhorse. Web each calculator provides inflation recommendations for their brand of tires only. To check tire pressure, use a calibrated pressure gauge.

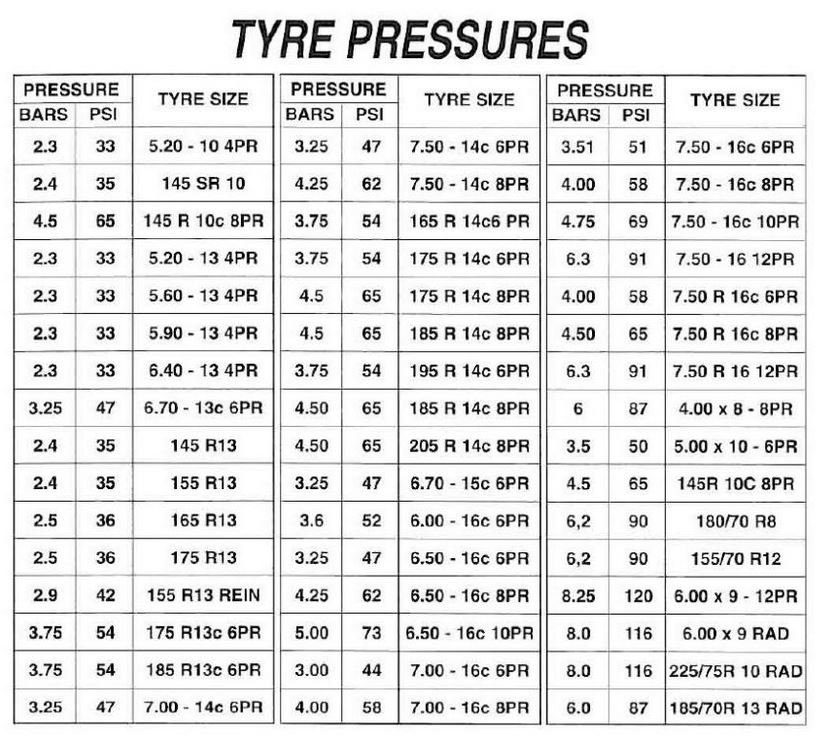

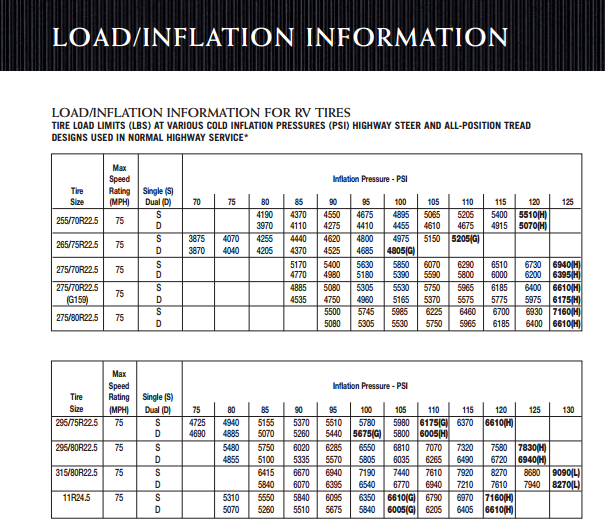

For intermediate inflation pressures and for tires not shown, the field service loads in table e may be increased by 87% for 6. Web get michelin's simple tools to perform functions like calculating your tractor's tire pressure or finding the right air pressure for your construction loader. Web for shipping purposes, tire inflation pressures may be increased to 30 psi (210 kpa). Web utilize these tire pressure charts to calculate the correct minimum psi based on tire size and load limits. A lot of these machines, you can have eight to 10 different tire options for the machine.

Web this article introduces a comprehensive tractor tire psi chart detailing tire size and load index to guide you in maintaining your tractor’s tires for peak condition and longevity. Web that led to putting in strain gauges to know the load on each tire, capturing the speed of the planter from the tractor system, and loading tire inflation tables to compute the tire pressure needed for each wheel as the weight would shift. For intermediate inflation pressures and for tires not shown, the field service loads in table e may be increased by 87% for 6. Inflate to the air pressure that is appropriate for. At 80psi, a 265/75r16 10ply itire will carry 3,085 pounds of load. Web utilize these tire pressure charts to calculate the correct minimum psi based on tire size and load limits. Web here are the six steps that will help determine the optimum tire inflation rate for your equipment. Calculate the weight needed for proper tractor setup. Proper ballast and tire pressure will maximize traction and tire life while minimizing fuel consumption and compaction. * cyclic applications include the normal usages of loader, log stackers, etc. A decrease in tyre pressure allows you to reduce soil compaction but limits the load on each tyre. For cyclic loading service see table f2. Web determining the proper ballast and tire pressure for your tractor should be a key part of spring equipment maintenance. Web minimum recommended inflation pressures for tires with aspect ratio 90 and higher when used as singles are 50% of the rated inflation pressure, rounded to the nearest step below with a minimum of 80 kpa. This should come as no great surprise—after all, every field is different, and the load, weight, and ballasting vary widely from one tractor to the next.

Web That Led To Putting In Strain Gauges To Know The Load On Each Tire, Capturing The Speed Of The Planter From The Tractor System, And Loading Tire Inflation Tables To Compute The Tire Pressure Needed For Each Wheel As The Weight Would Shift.

Discover how to enhance your tractor’s efficiency,. An increase in pressure allows you to carry more load but increases soil compaction. Tire weight / tire pressure = load capacity pounds per psi. This should come as no great surprise—after all, every field is different, and the load, weight, and ballasting vary widely from one tractor to the next.

Calculate The Weight Needed For Proper Tractor Setup.

A lot of these machines, you can have eight to 10 different tire options for the machine. Web for shipping purposes, tire inflation pressures may be increased to 30 psi (210 kpa). The minimum load must not exceed 60% of. For cyclic loading service see table f2.

For Transport Service Above 20 Mph (30 Km/H), Recommended Minimum Inflation Pressure Is 8 Psi (60 Kpa).

Web determining the proper ballast and tire pressure for your tractor should be a key part of spring equipment maintenance. Inflate to the air pressure that is appropriate for. At 60 psi on a 10ply tire, the tire's load carrying capacity is reduced to 2,314 pounds per tire. Inflation pressure must be adjusted to correct operating inflation before placing tires in service.

The Above Loads Are Also Applicable To Equipment, Including Hillside Combines, Operating On Slopes Above 11° (20% Grade).

Web get michelin's simple tools to perform functions like calculating your tractor's tire pressure or finding the right air pressure for your construction loader. Web checking that tire inflation pressure there, it gives a whole chart of all of the different tires that could be potentially on your tractor. Dual tractor tire load pressure chart. For optimum performance, set all tires on an axle to the same pressure.