Overhead, horizontal, vertical, and flat. Let’s delve deeper into the importance of selecting the correct rod size. So, choosing the appropriate welding rod size is crucial. Plus you'll get the most complete welding rod chart on the internet in pdf! 3.2 how welding positions affect electrode size choice.

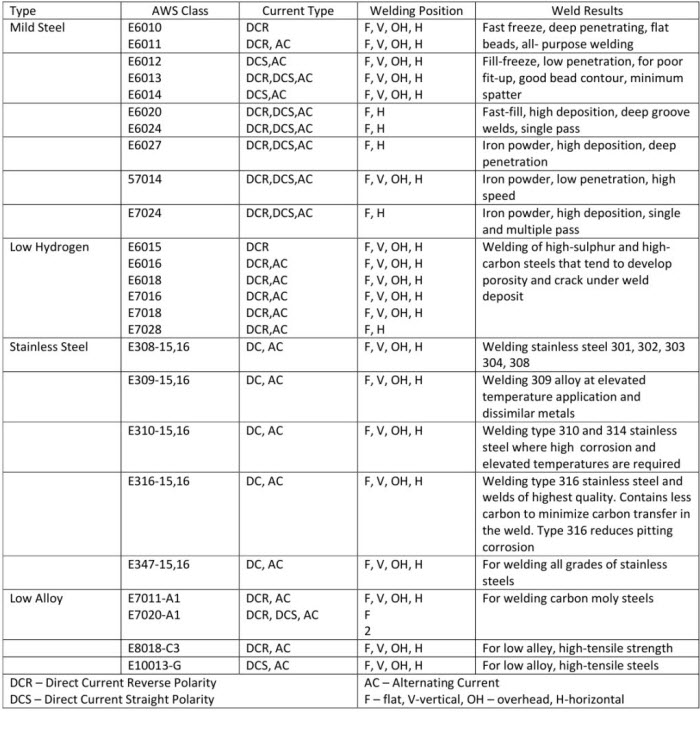

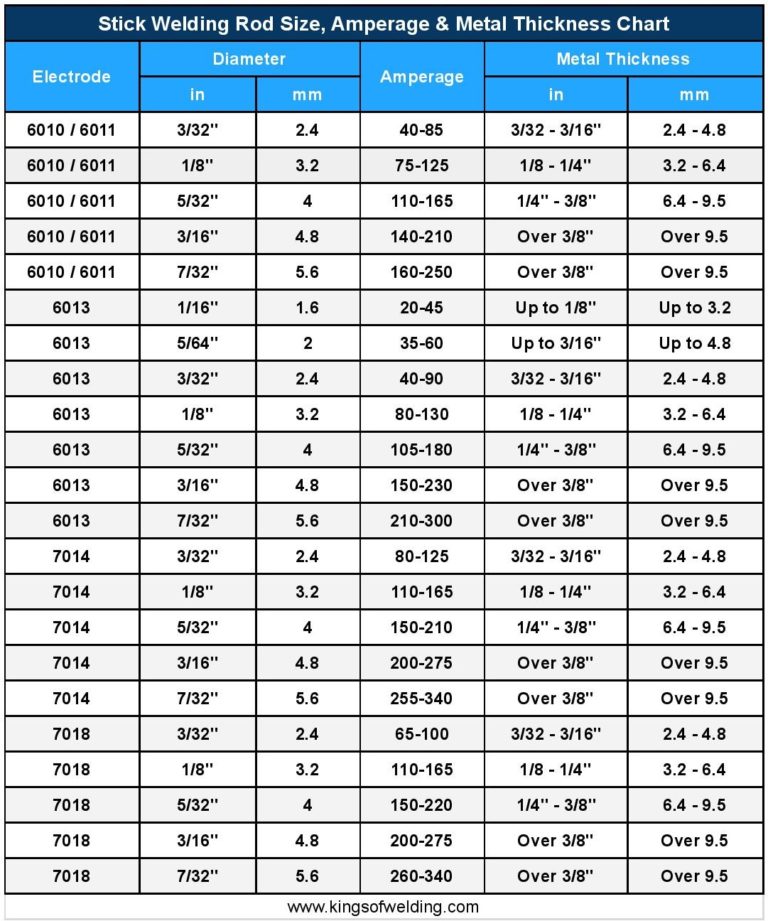

Web welding rod sizes explained. Web neglecting position and joint type. We have gone into this in more detail below. This chart provides valuable information on which rod size to use for different metal thicknesses and welding positions. The electrode identification system for steel arc welding is set up as follows:

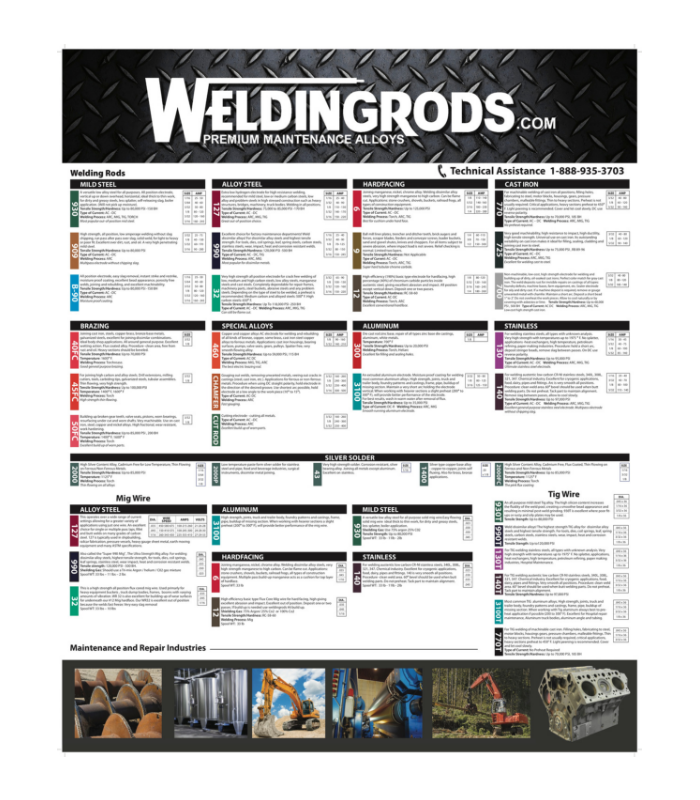

We have gone into this in more detail below. Web this chart provides an overview of the most common stick welding rod sizes and their corresponding classifications. In one of these packets, there are about 277 rods. This chart provides valuable information on which rod size to use for different metal thicknesses and welding positions. Web what are welding rods?

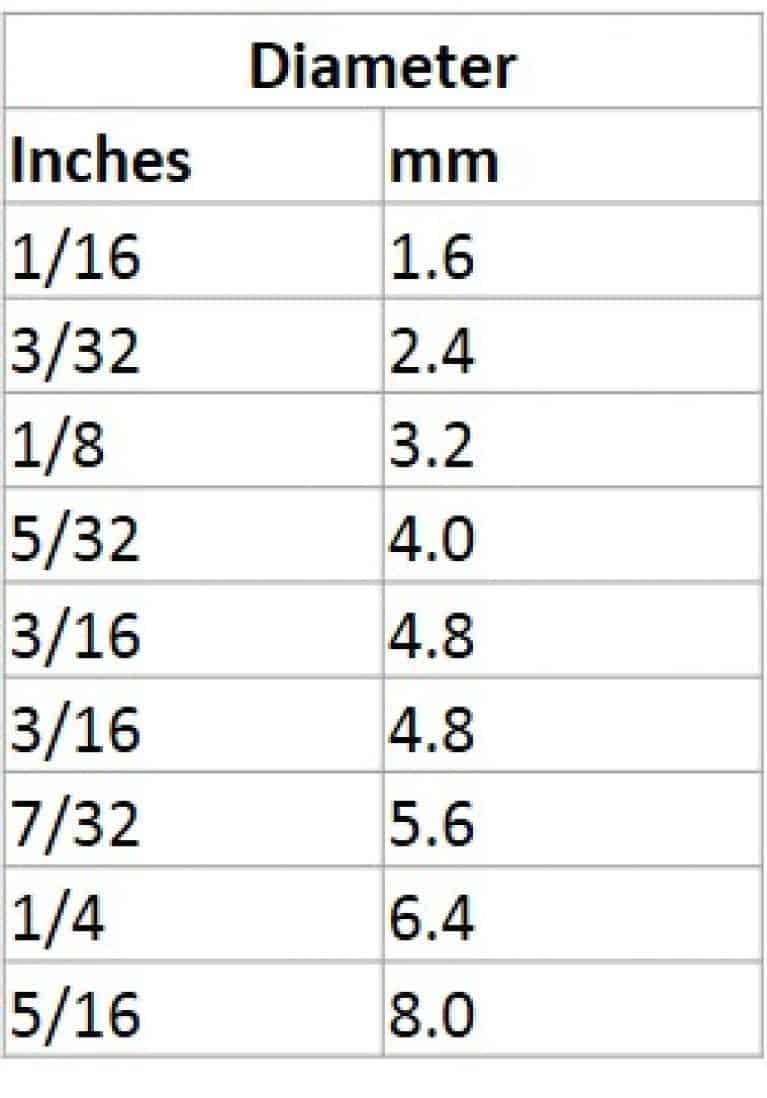

Proper rod storage to retain performance. The electrode identification system for steel arc welding is set up as follows: Web stick welding rod size, amperage & metal thickness chart. Web see our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables. Below is a chart that will give you a starting point for choosing the correct welding rod size. Web what are welding rods? The welding industry has adopted the american welding society’s classification number series for welding rod electrodes. Some of the most common welding rod sizes include: Click here to see the welding rod chart in pdf format. Web you can use below welding rod sizes chart to choose the welding amperage for different diameters of welding rods used for carbon steel welding. 2.1 how is welding rod diameter measured? Web welding rod sizes explained. Understanding stick welding rod classification is essential in selecting the correct electrode for your welding needs. Balancing quality and economic factors. Web if you are looking for welding rod charts, we created the ultimate resource, listing everything from electrode sizes and amps to how much welding rod you need

Ensures The Electrode Meets The Required Joint Strength.

Web if you are looking for welding rod charts, we created the ultimate resource, listing everything from electrode sizes and amps to how much welding rod you need These guidelines can vary between different manufacturers so always check the manufacturer’s guidelines if possible. Selecting the correct rod size. Web this chart provides an overview of the most common stick welding rod sizes and their corresponding classifications.

This Size Is Used For Carbon Steel.

3.2 how welding positions affect electrode size choice. 2.1 how is welding rod diameter measured? Web this page serves as a point of reference and a guide for selecting the right stick welding rod size and amperage to get the best results when stick welding. Web below is a chart of the different types of stick welding rod and explanations of what the different numbers mean.

Plus You'll Get The Most Complete Welding Rod Chart On The Internet In Pdf!

Web neglecting position and joint type. The electrode identification system for steel arc welding is set up as follows: Anything up to 1/4″ (6.35 mm) thick would be best welded with a 1/8″ (3.2 mm) electrode, and thicker metal would use 5/32″ (4.0 mm). The welding rod is used to carry electrical current through the workpiece and join two pieces.

We Have Gone Into This In More Detail Below.

You can’t use a rod that doesn’t run on your power supply. Web see our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables. Let’s delve deeper into the importance of selecting the correct rod size. What size welding rod for general purpose?