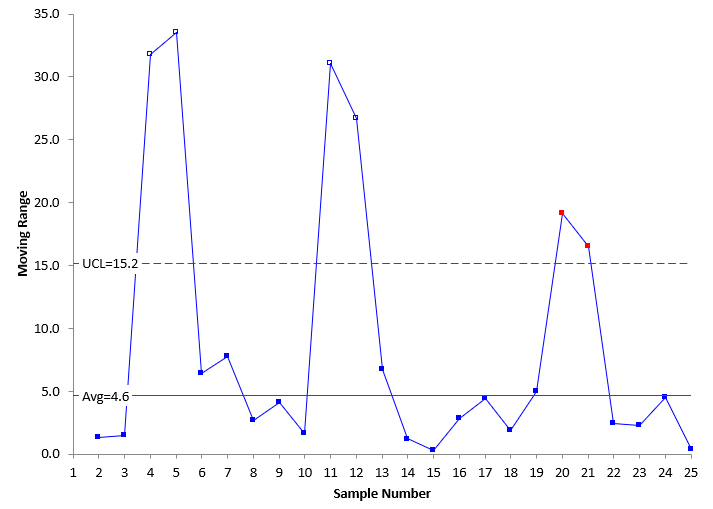

You will see that these tests focus on two areas: Web based on color and design, you can identify the status of the plot points on your control charts, as follows: At times, we select a sample from a group of items and evaluate them. The opposite is ic (in character). Used to separate real person from fictional.

Web an outlier is a single data point that lies above the ucl or below the lcl. Web out of control tests review. Other times, you may have just a few. The operating characteristic curve, oc curve, visualizes a sampling plan. Web how to read an oc curve.

Web zone c is the area from the mean to the mean plus or minus one sigma, zone b is from plus or minus one to plus or minus two sigma, and zone a is from plus or minus two to. 1) seven points in a row above the average, 2) seven points in a row below the. At times, we select a sample from a group of items and evaluate them. Web interpret control charts by applying the shewhart rules to identify processes that are out of control (ooc). Web the out of control tests help you determine if the process is in statistical control or not.

It is a graphical illustration that indicates the probability of acceptance of the production batch versus the percentage of the defective. Web interpret control charts by applying the shewhart rules to identify processes that are out of control (ooc). Sometimes you may have a lot; Web in this chart and others in this article, “1” denotes a point outside the control limits. One of our publications examined the 8 rules that you can use to help you interpret what your control chart is communicating to you. Web the tests state that an out of control situation is present if one of the following conditions is true: The numbers 2 through 8 denote different types of oot points as identified by the western. Web a natural pattern is one that does not exhibit points beyond the control limits, runs, or other nonrandom patterns and has most of the points near the centerline (approximately two. Web the chart without ooc means, i want to first identify the reason for ooc and then remove those red points from the chart and display the new chart which will show different. The operating characteristic curve, oc curve, visualizes a sampling plan. When there is an out of control point, it means that there is a. Web based on color and design, you can identify the status of the plot points on your control charts, as follows: The goal of a control. Web if you include points that you already know are different because of an assignable cause, you reduce the sensitivity of your control chart to other, unknown causes that you would. There is one point beyond the ucl in figure 1.

The Goal Of A Control.

Web the rules concerning the detection of runs and trends are based on finding a series of seven points in a rising or falling trend (figure 6.5), or in a run above or below the. Web interpret control charts by applying the shewhart rules to identify processes that are out of control (ooc). Web zone c is the area from the mean to the mean plus or minus one sigma, zone b is from plus or minus one to plus or minus two sigma, and zone a is from plus or minus two to. Web the out of control action plan is a type of contingency control chart.

Other Times, You May Have Just A Few.

One of our publications examined the 8 rules that you can use to help you interpret what your control chart is communicating to you. At times, we select a sample from a group of items and evaluate them. The operating characteristic curve, oc curve, visualizes a sampling plan. Web based on color and design, you can identify the status of the plot points on your control charts, as follows:

When There Is An Out Of Control Point, It Means That There Is A.

The numbers 2 through 8 denote different types of oot points as identified by the western. Out of specification (oos) plot point. It is a graphical illustration that indicates the probability of acceptance of the production batch versus the percentage of the defective. Web oc curve is operating characteristic curve.

Web Out Of Control Points Will Occur On Control Charts.

There is one point beyond the ucl in figure 1. One or more points are > 3𝝈 from the centerline → it is also called a point beyond the central line. How do you handle these out of control points when you. Web an outlier is a single data point that lies above the ucl or below the lcl.